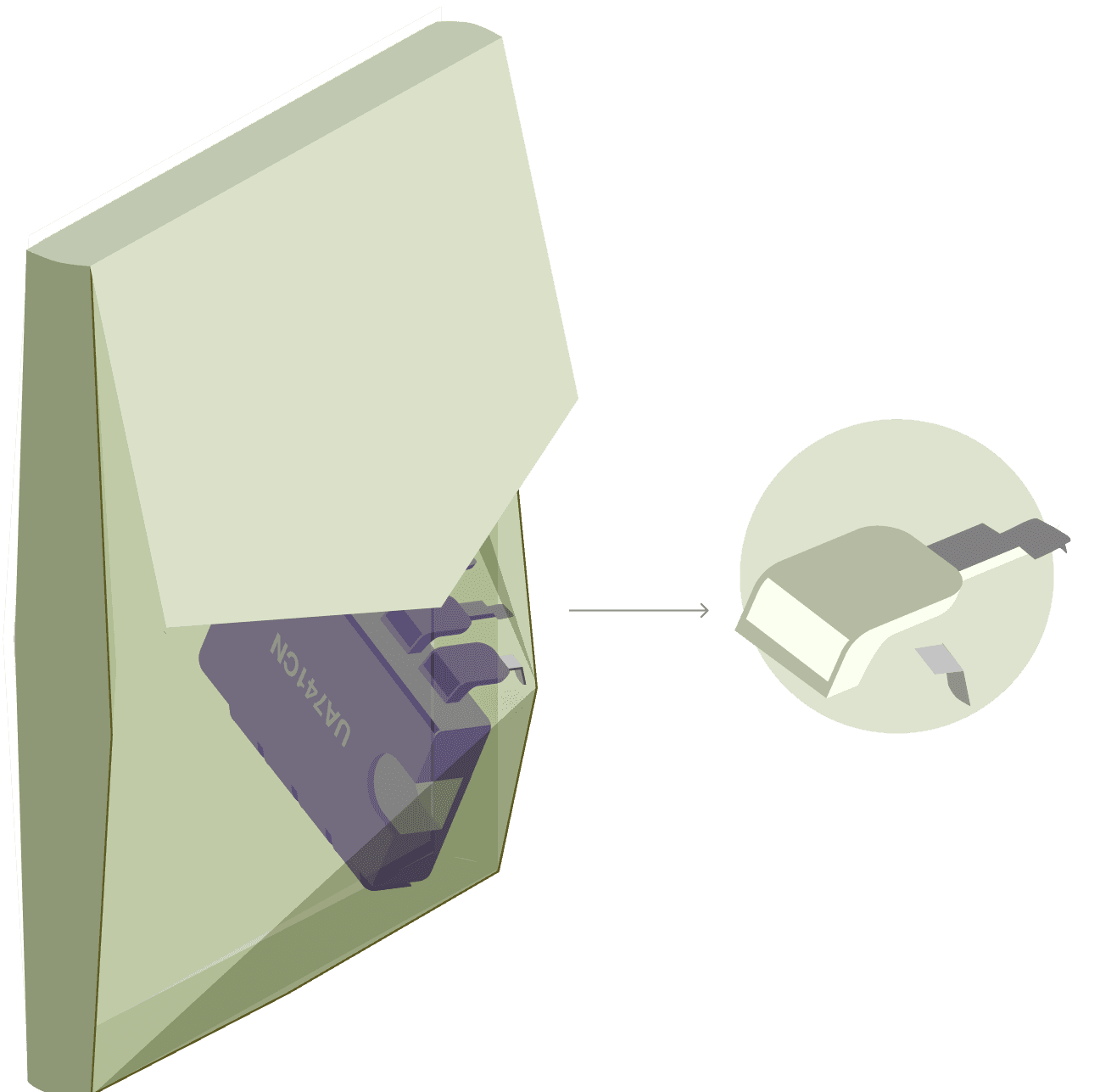

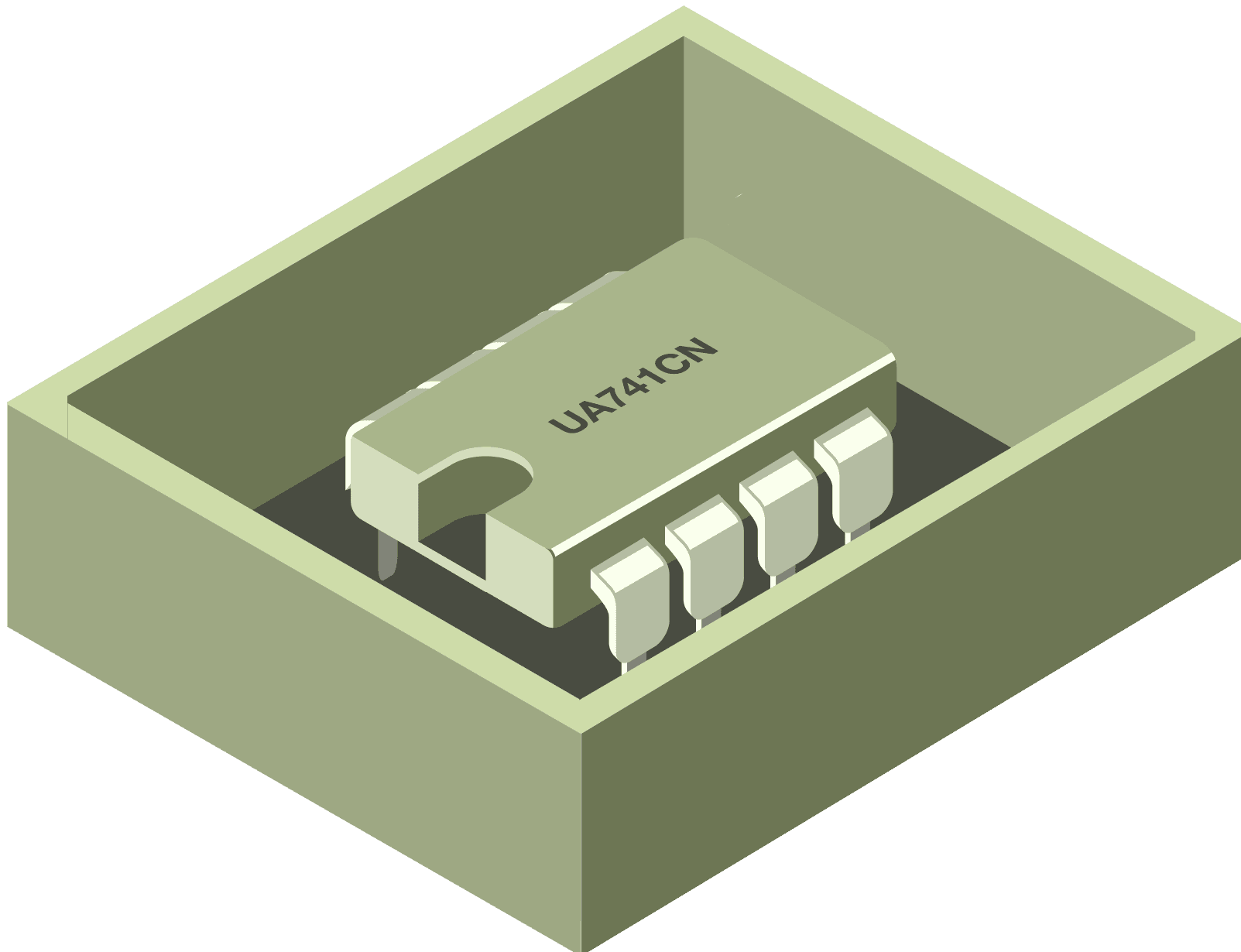

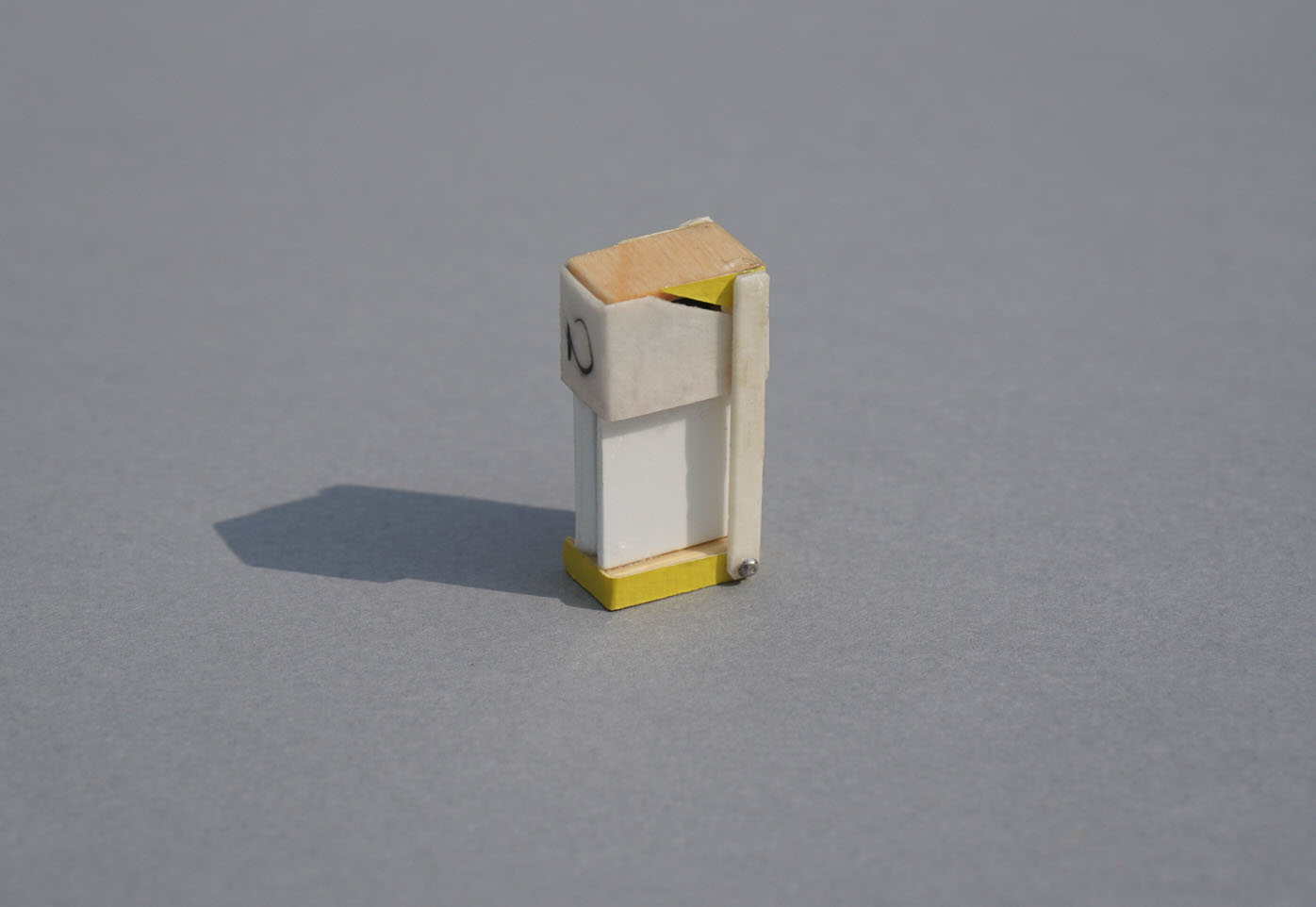

A Packaging for IC Chips

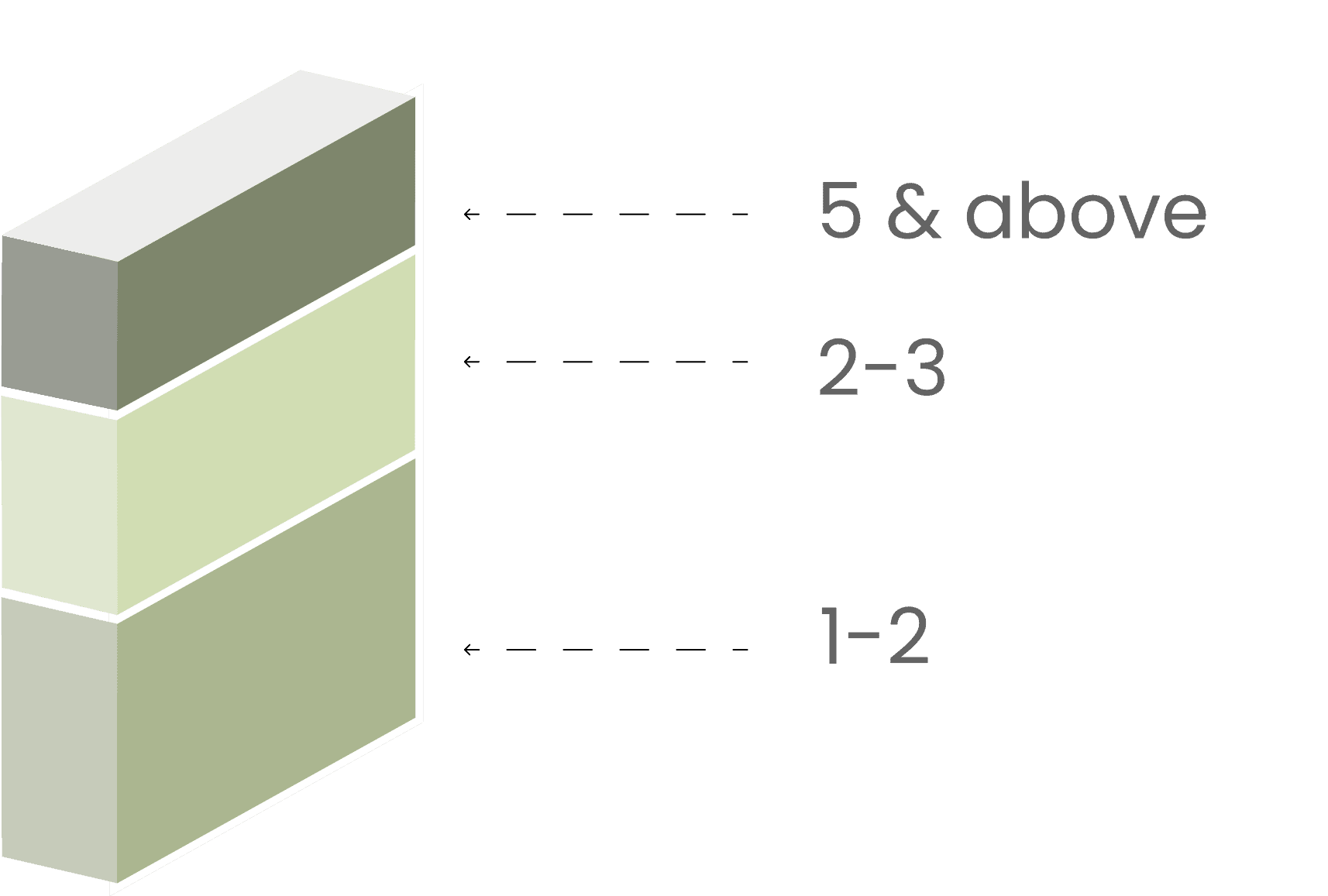

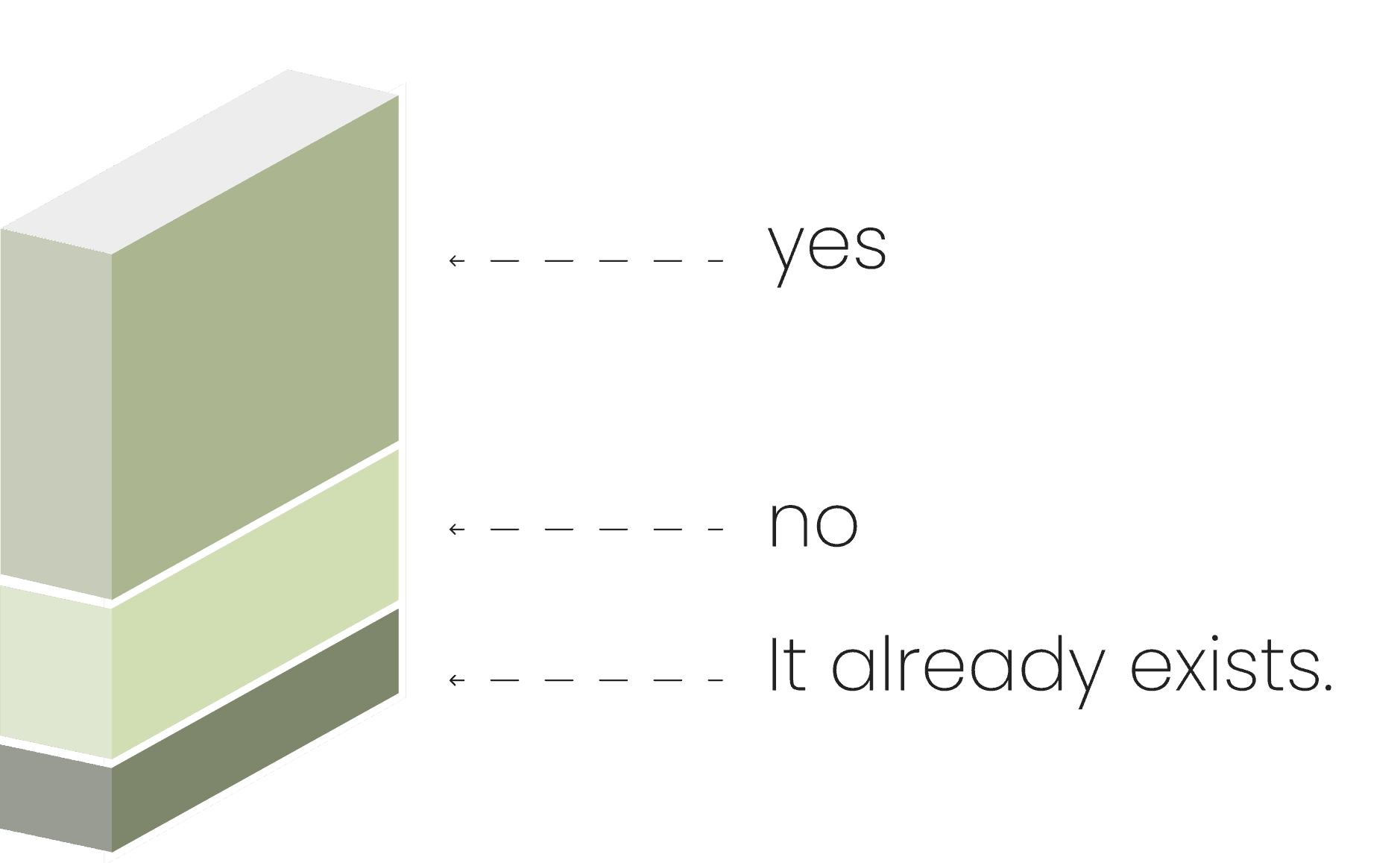

Safer and compact?

Beginner Friendly?

Instructive?

For anyone who needs electronic parts

to be safer, clearer, and easier to store.

(students, hobbyists, and shopkeepers)

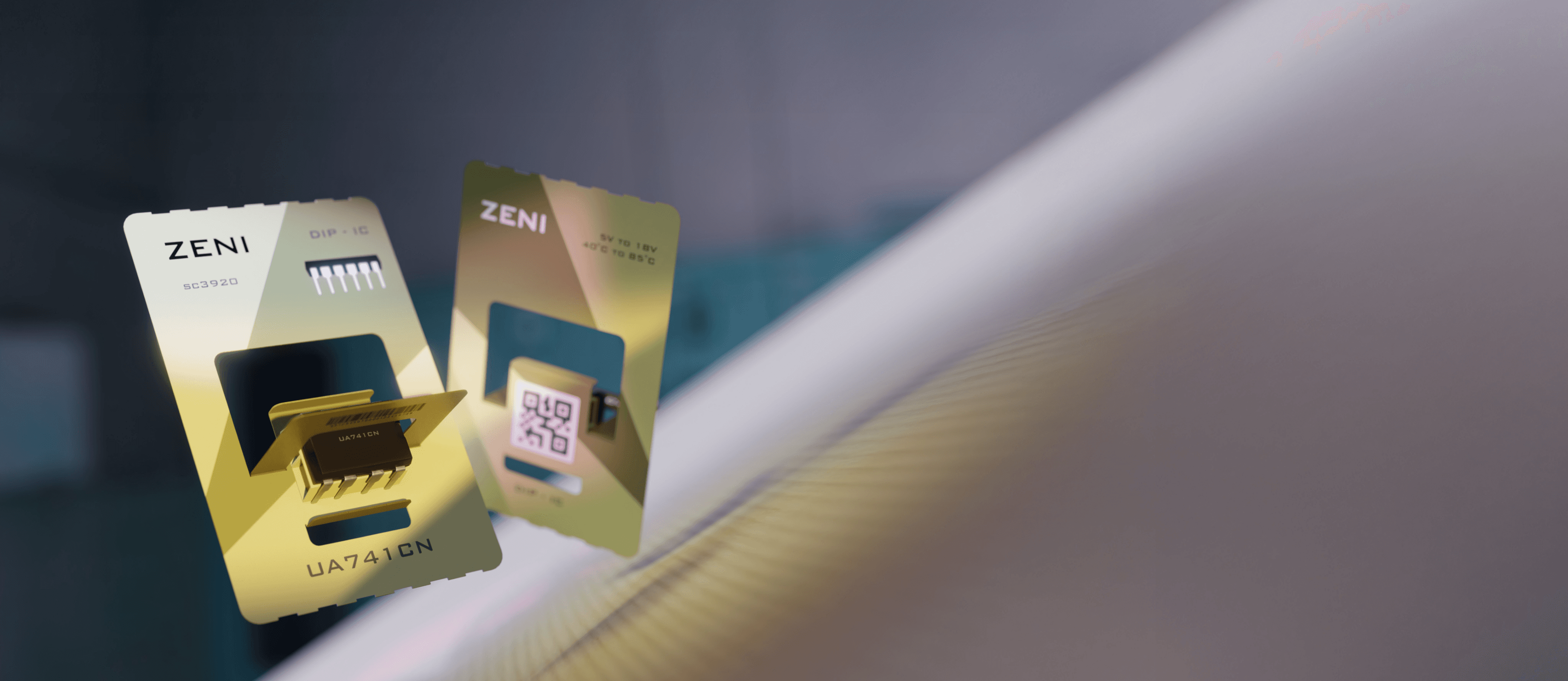

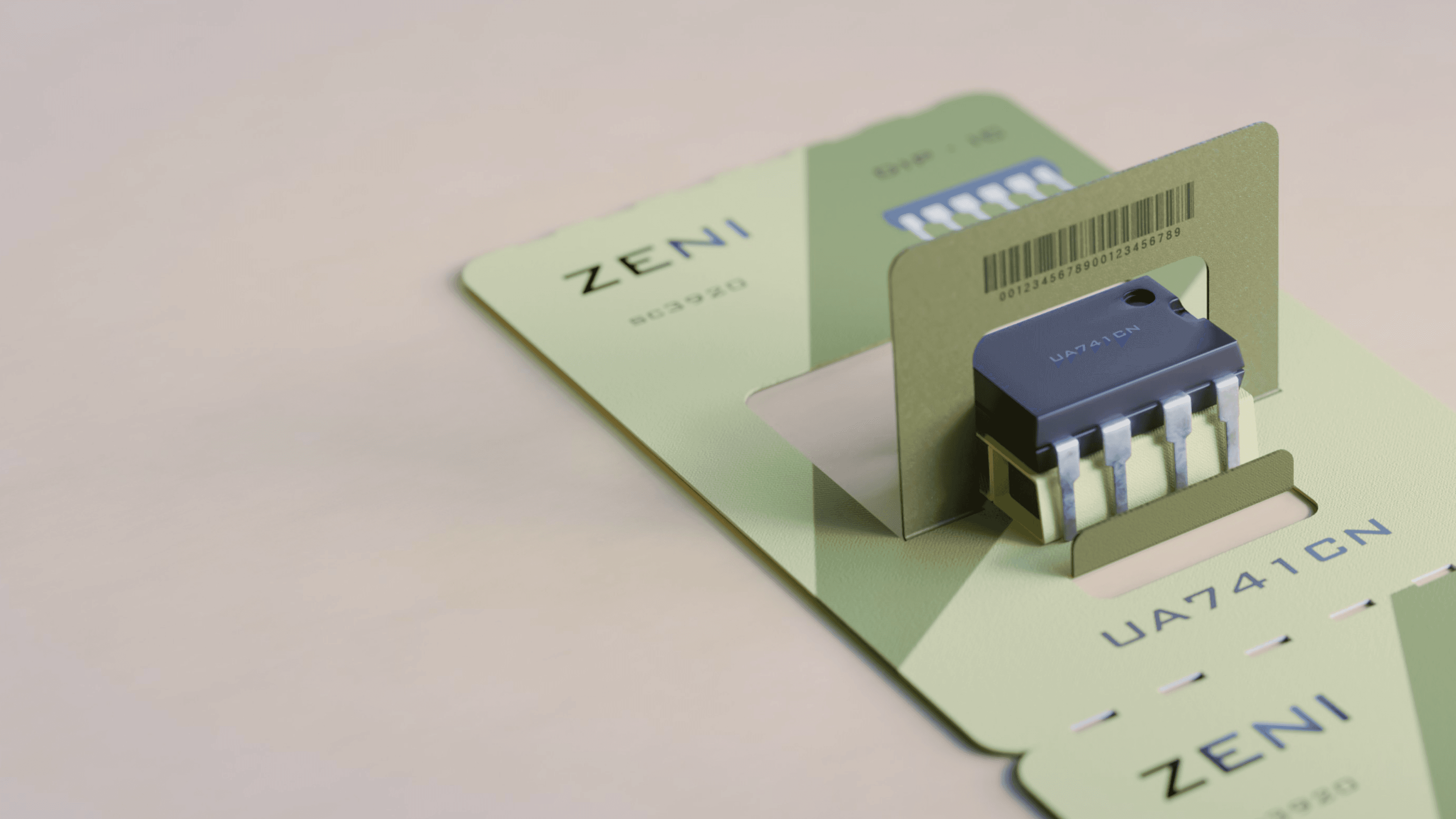

A packaging that stores, organizes and guides.

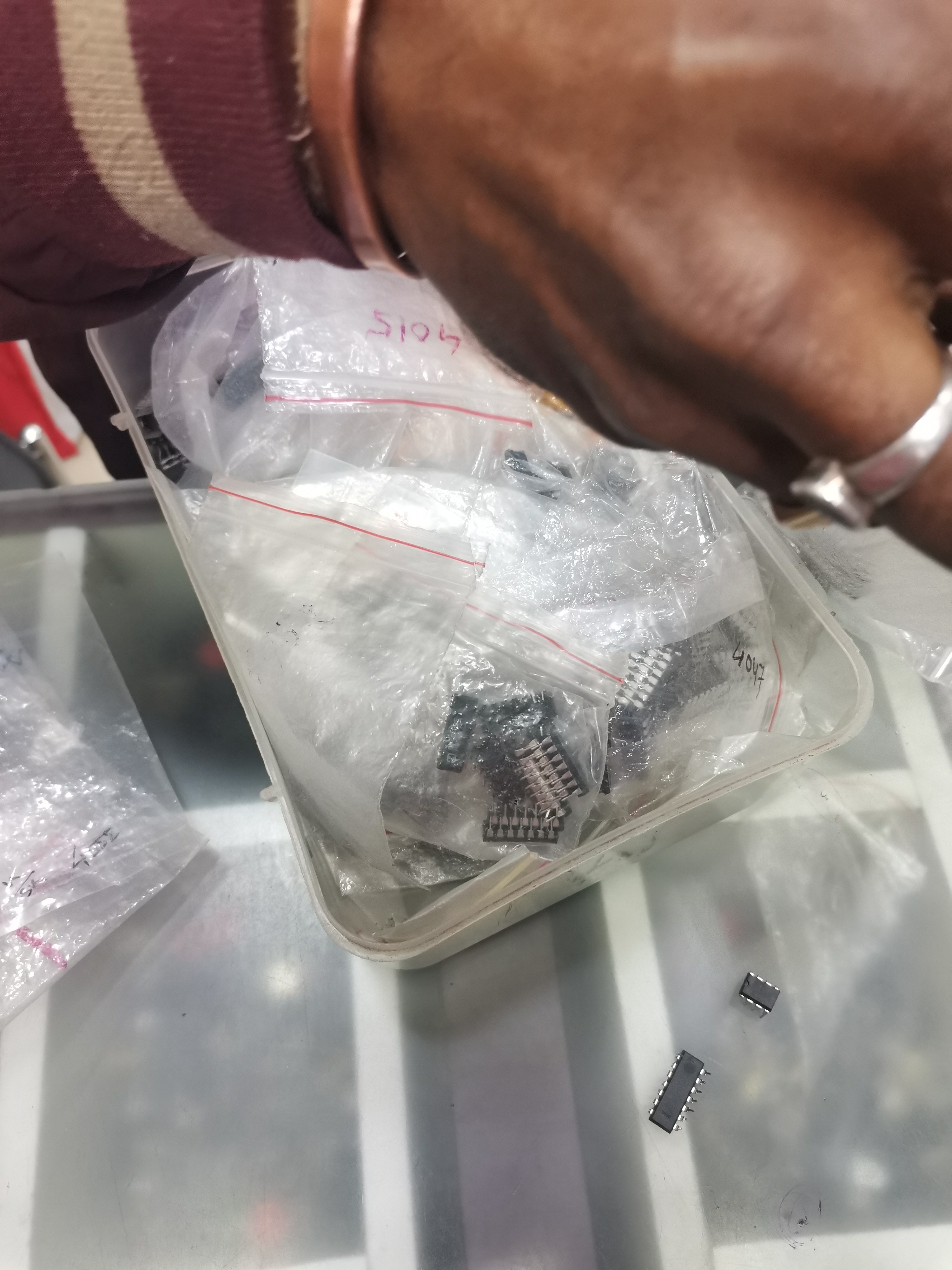

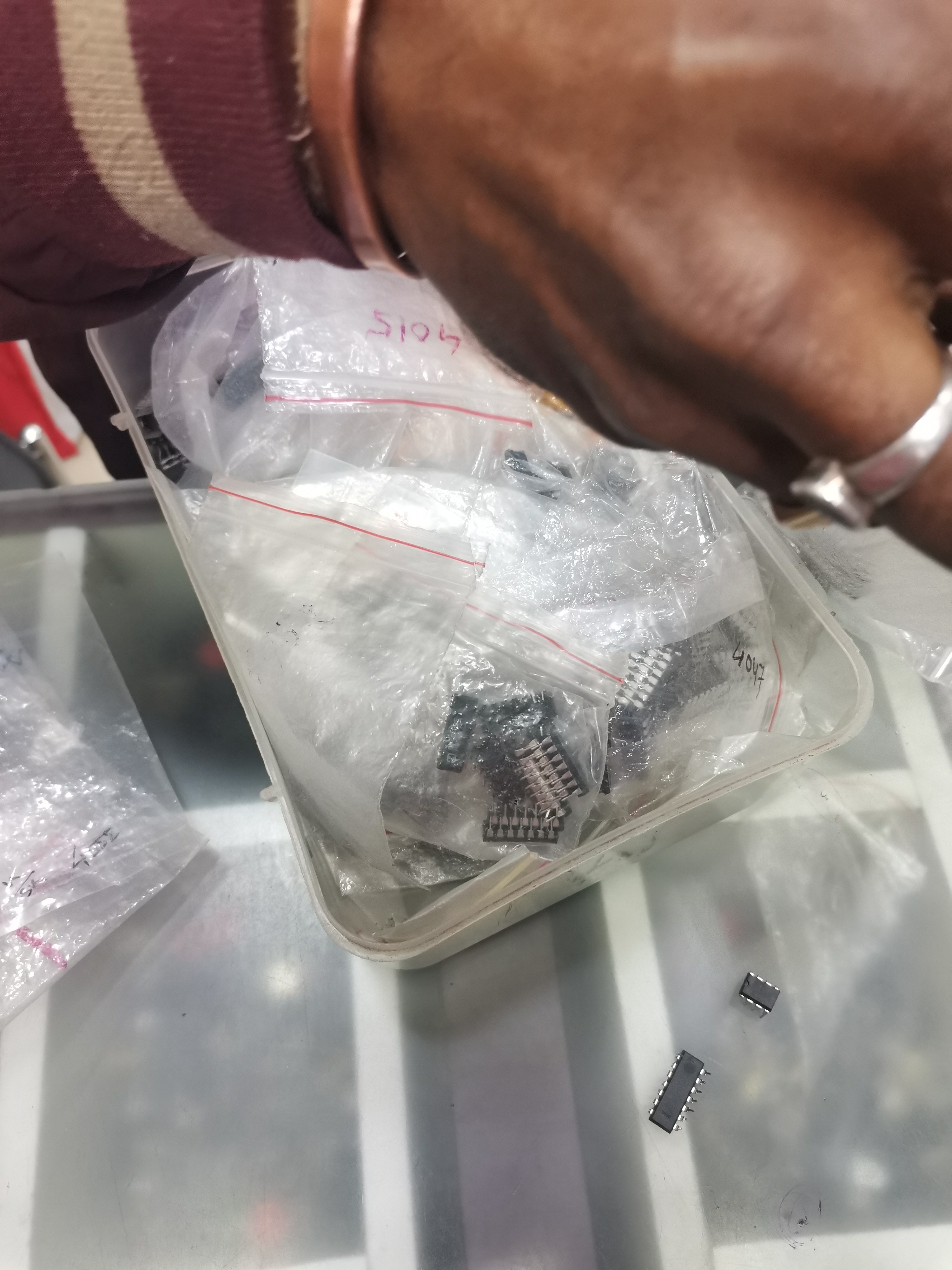

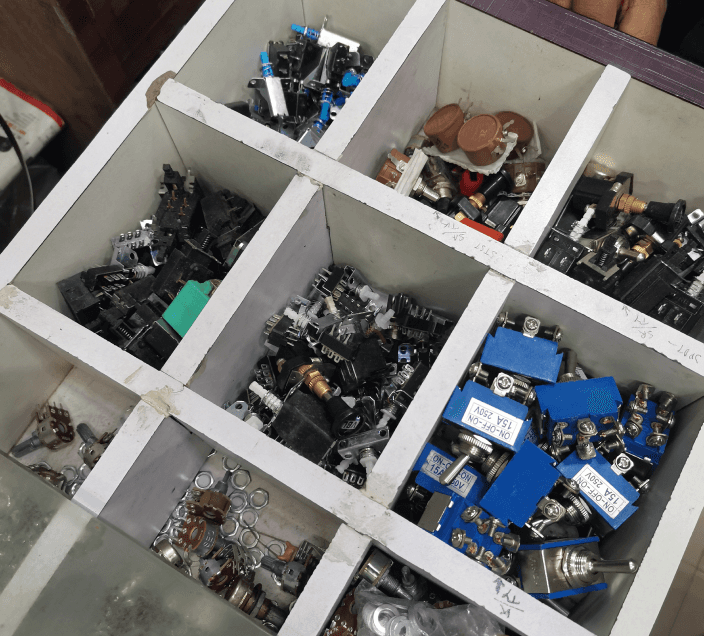

(Shops selling single ICs.

Drawers and pouches where parts get lost.

Workbenches of students, hobbyists, and beginners.)

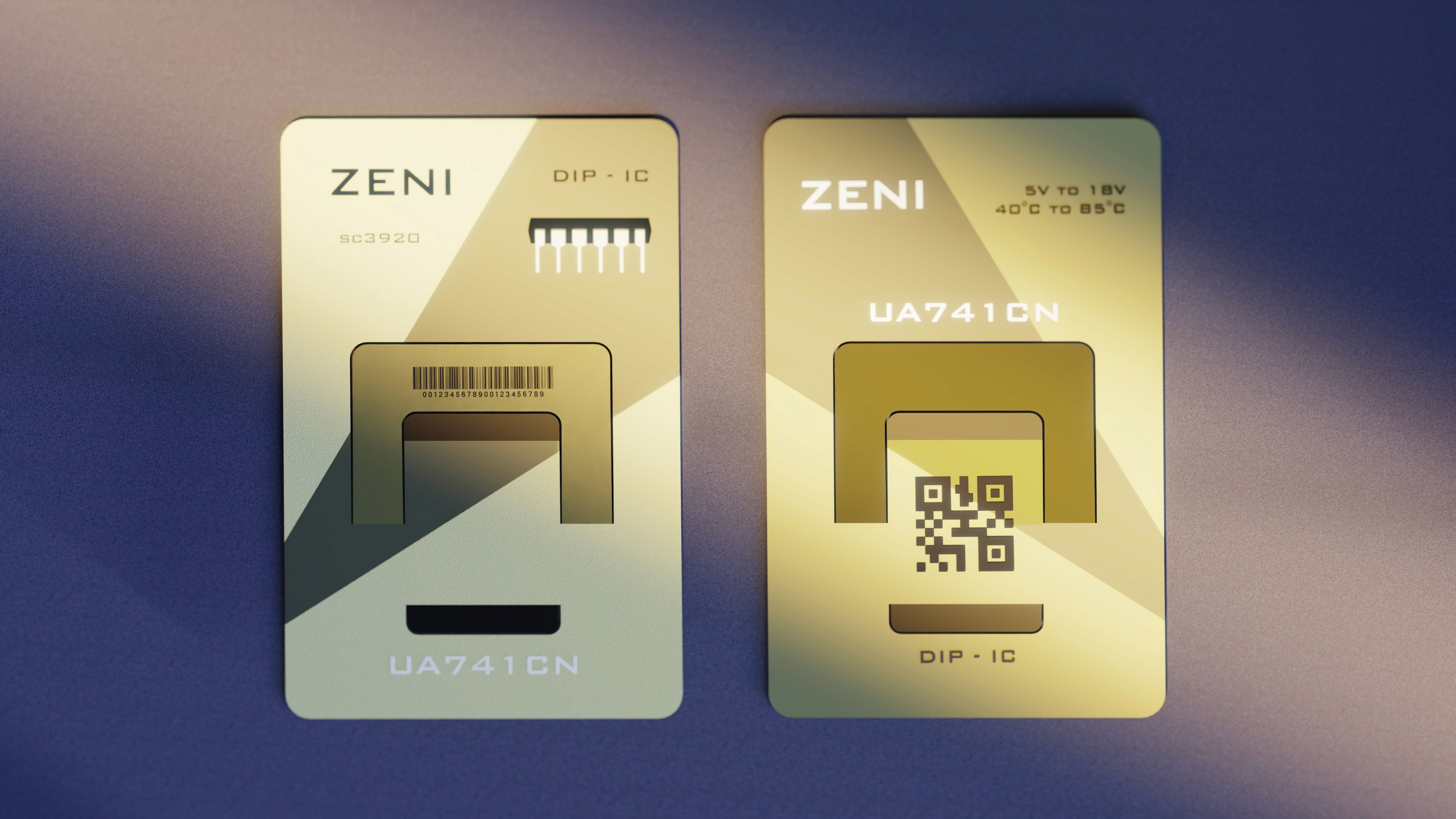

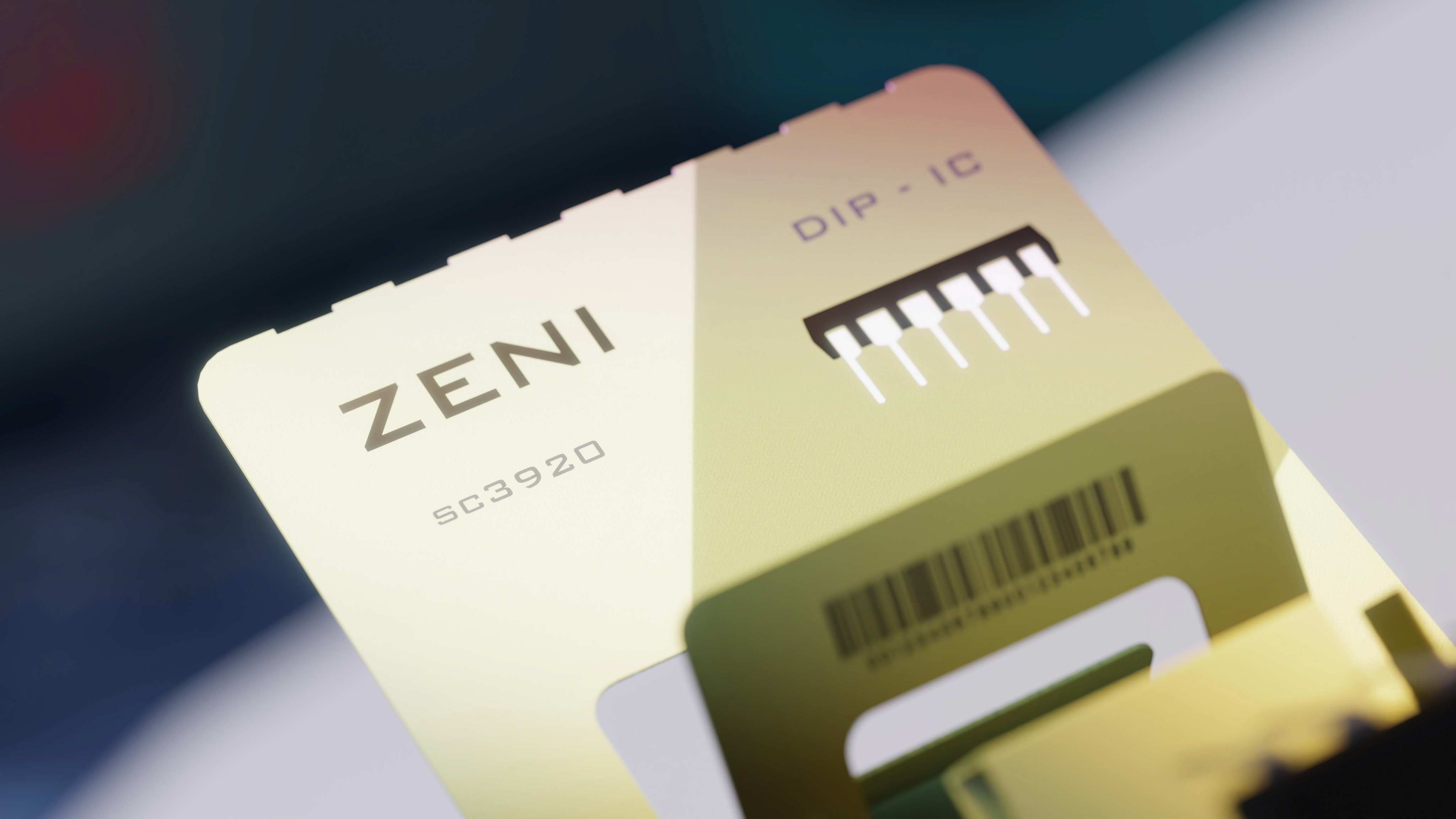

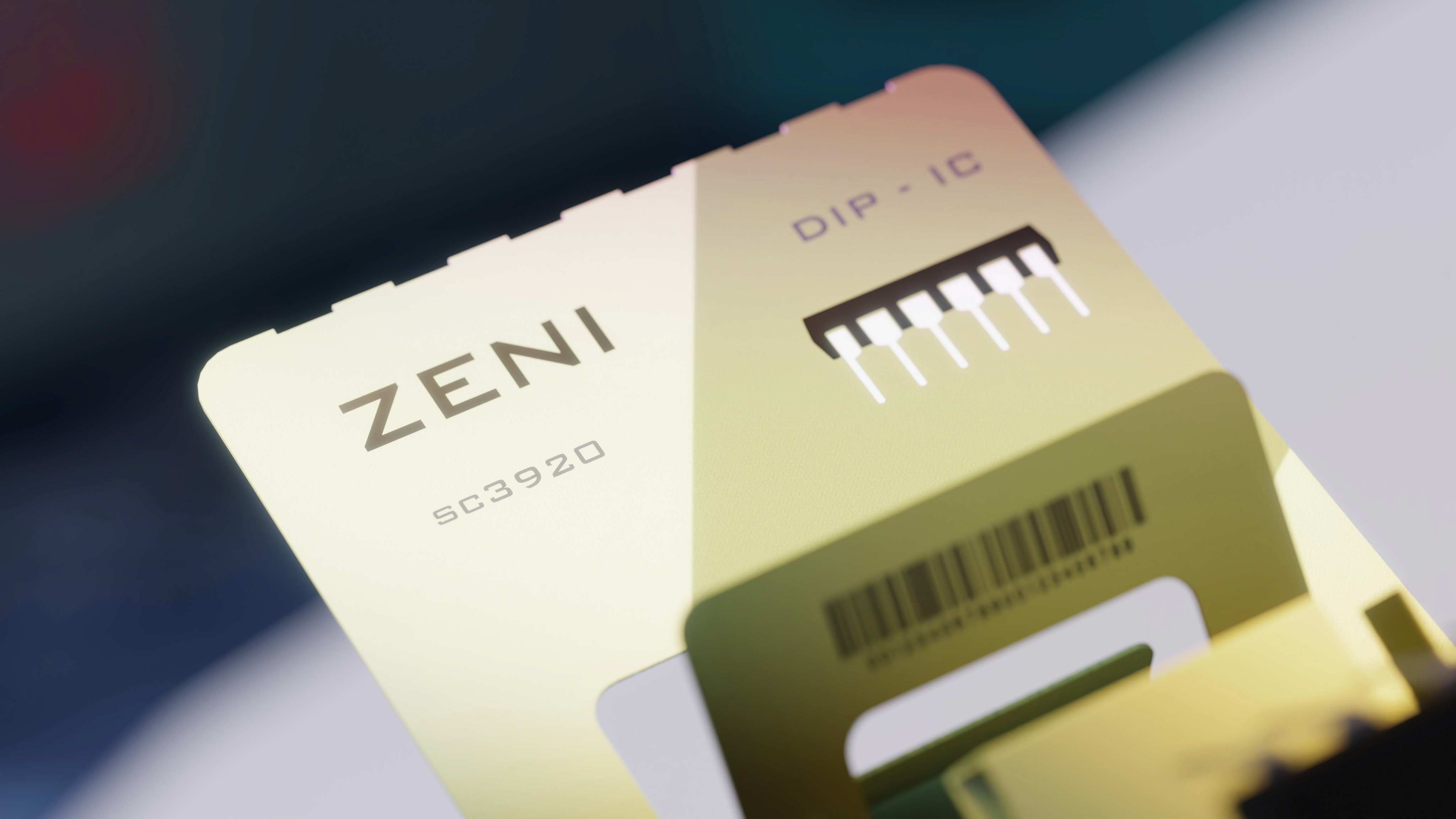

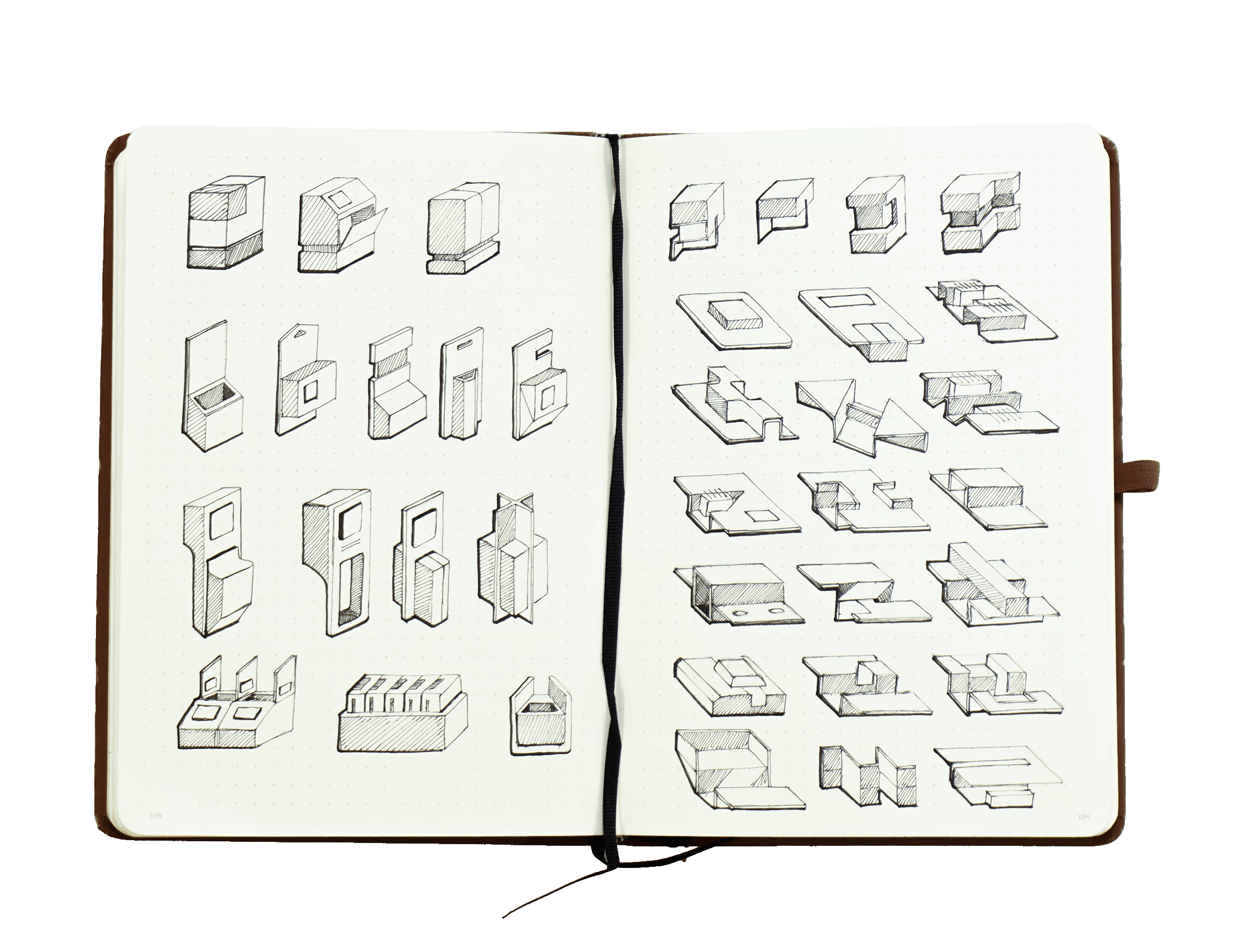

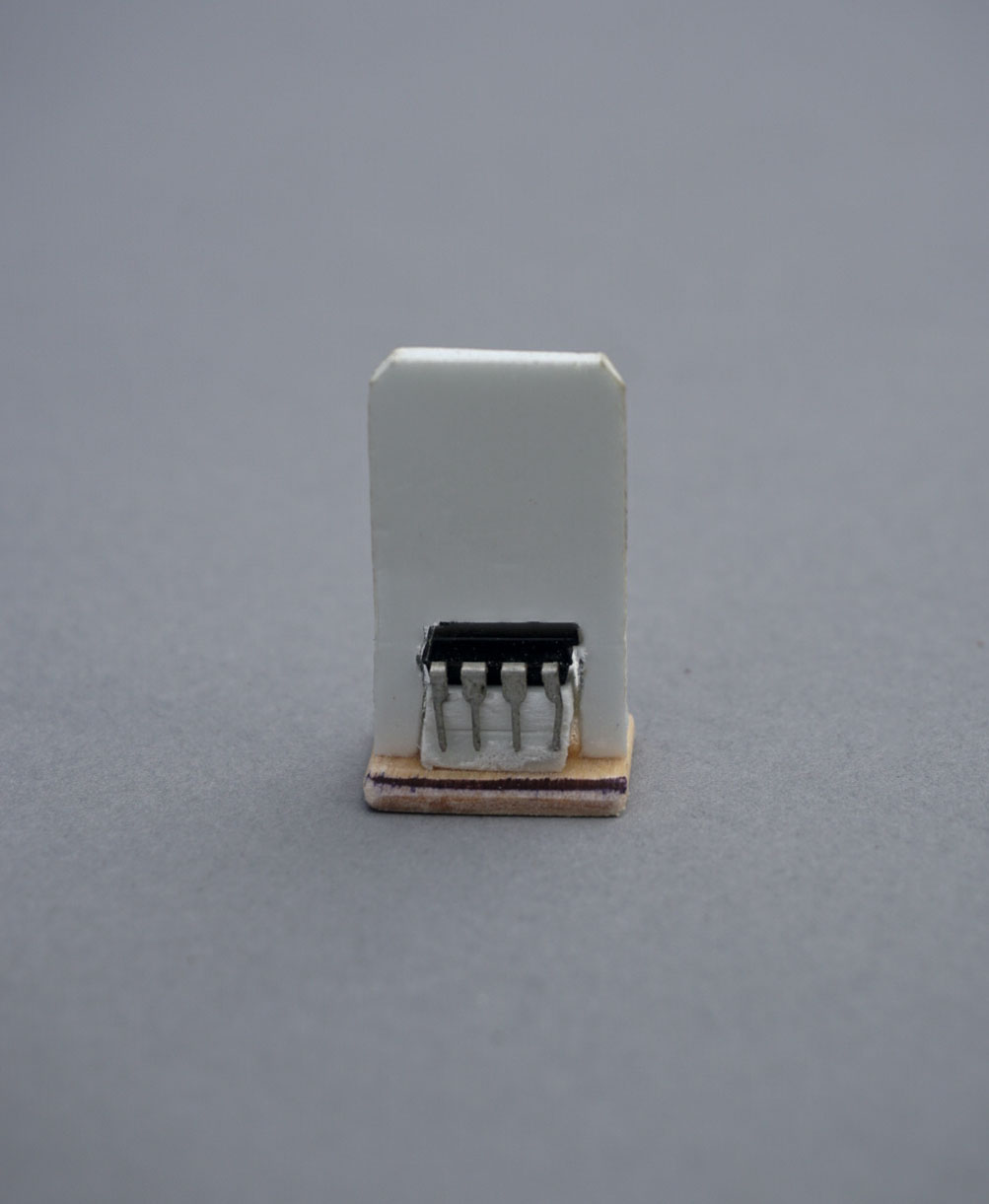

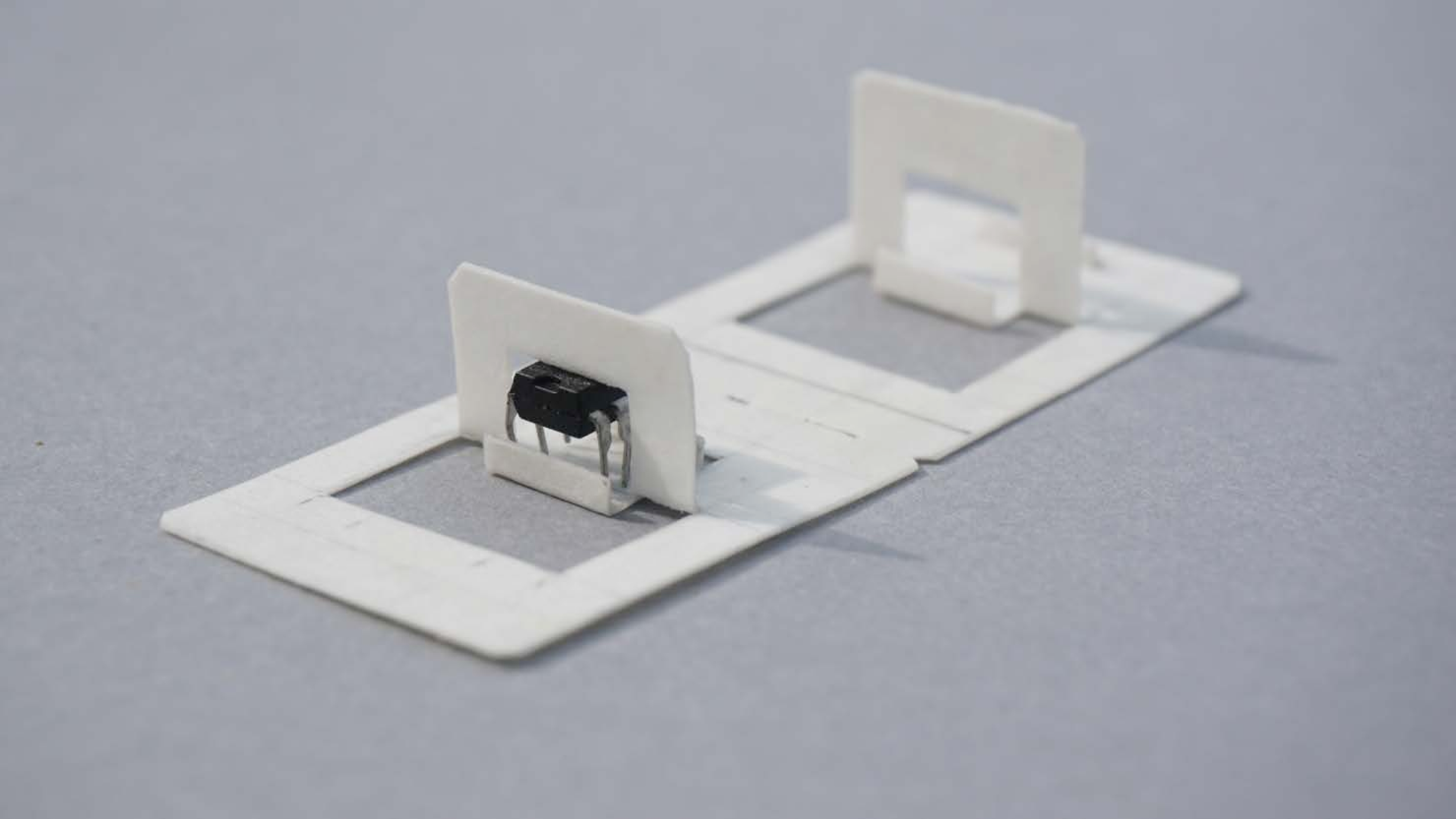

Designed with responsibility: minimal plastic,

Simple die-cuts for easy manufacturing,

Tested protection for real use,

Clear labels with QR codes for guidance.

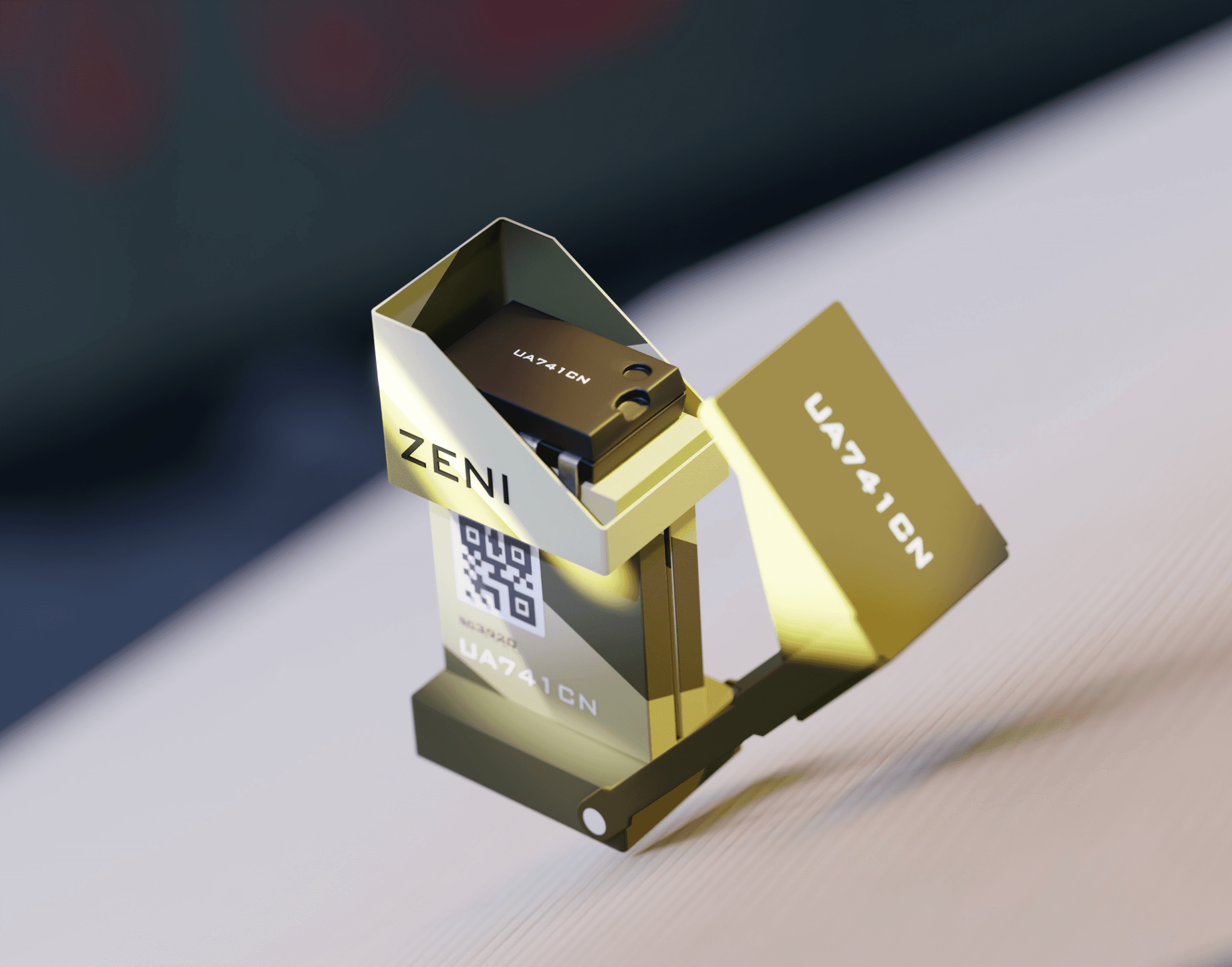

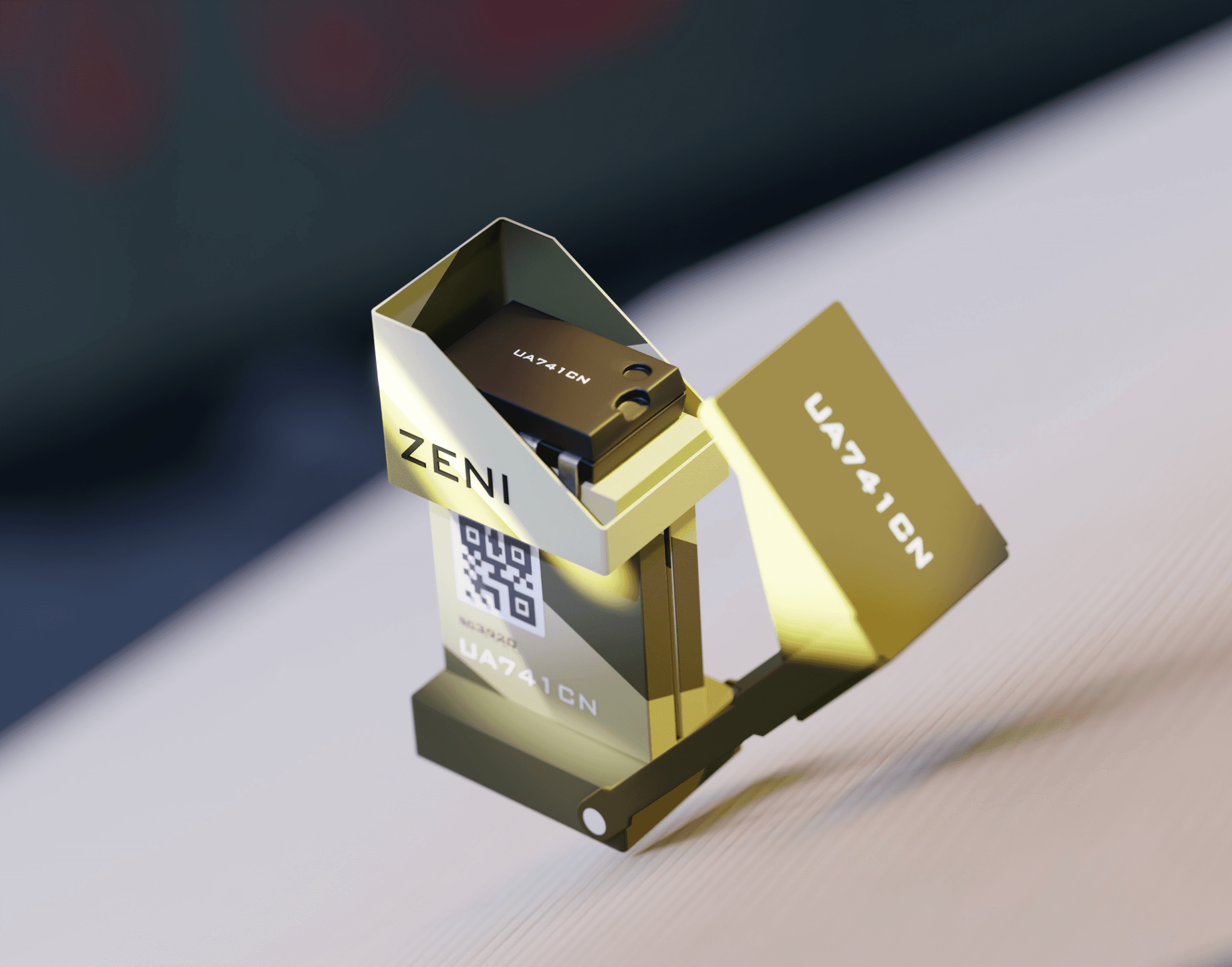

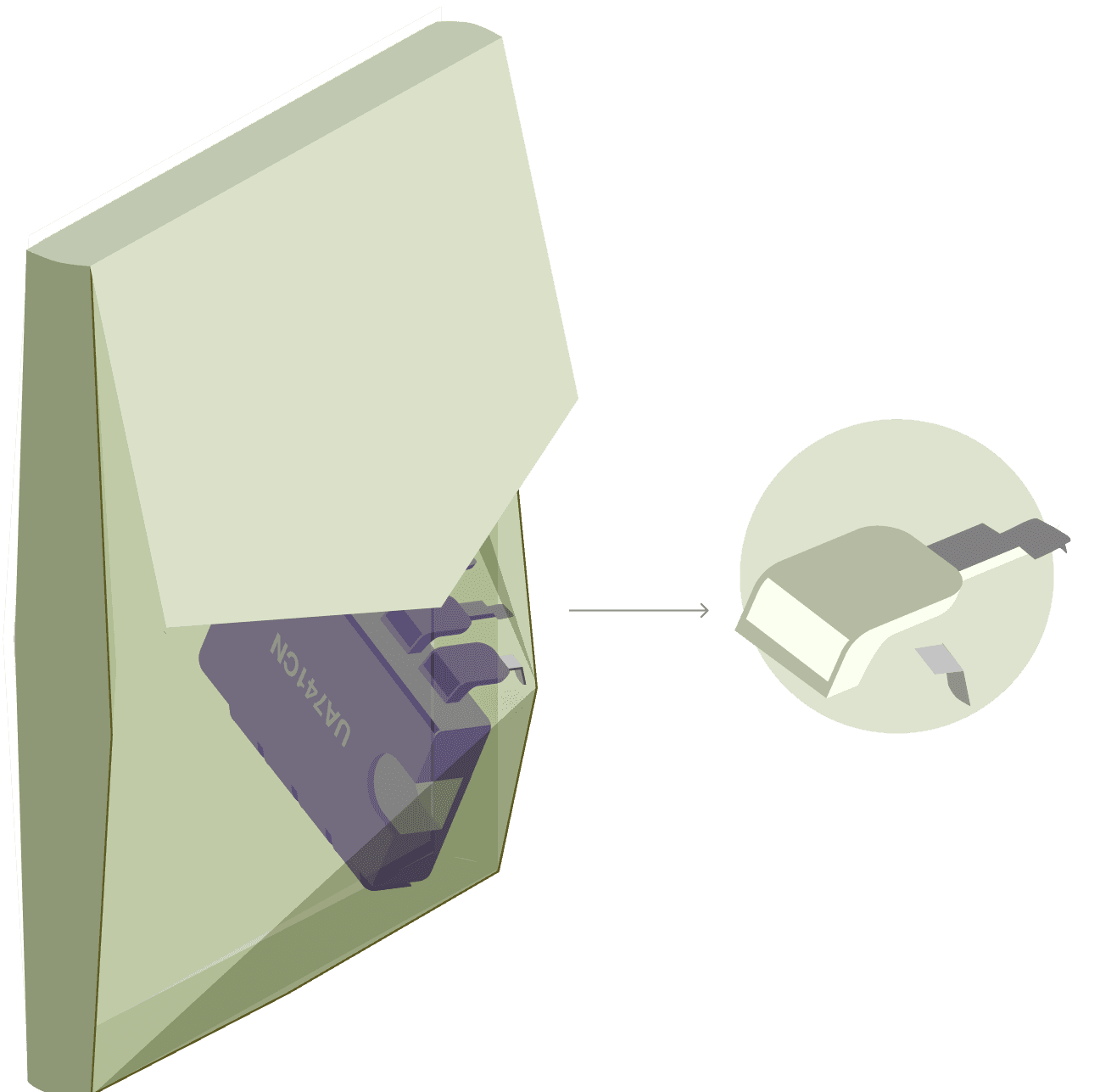

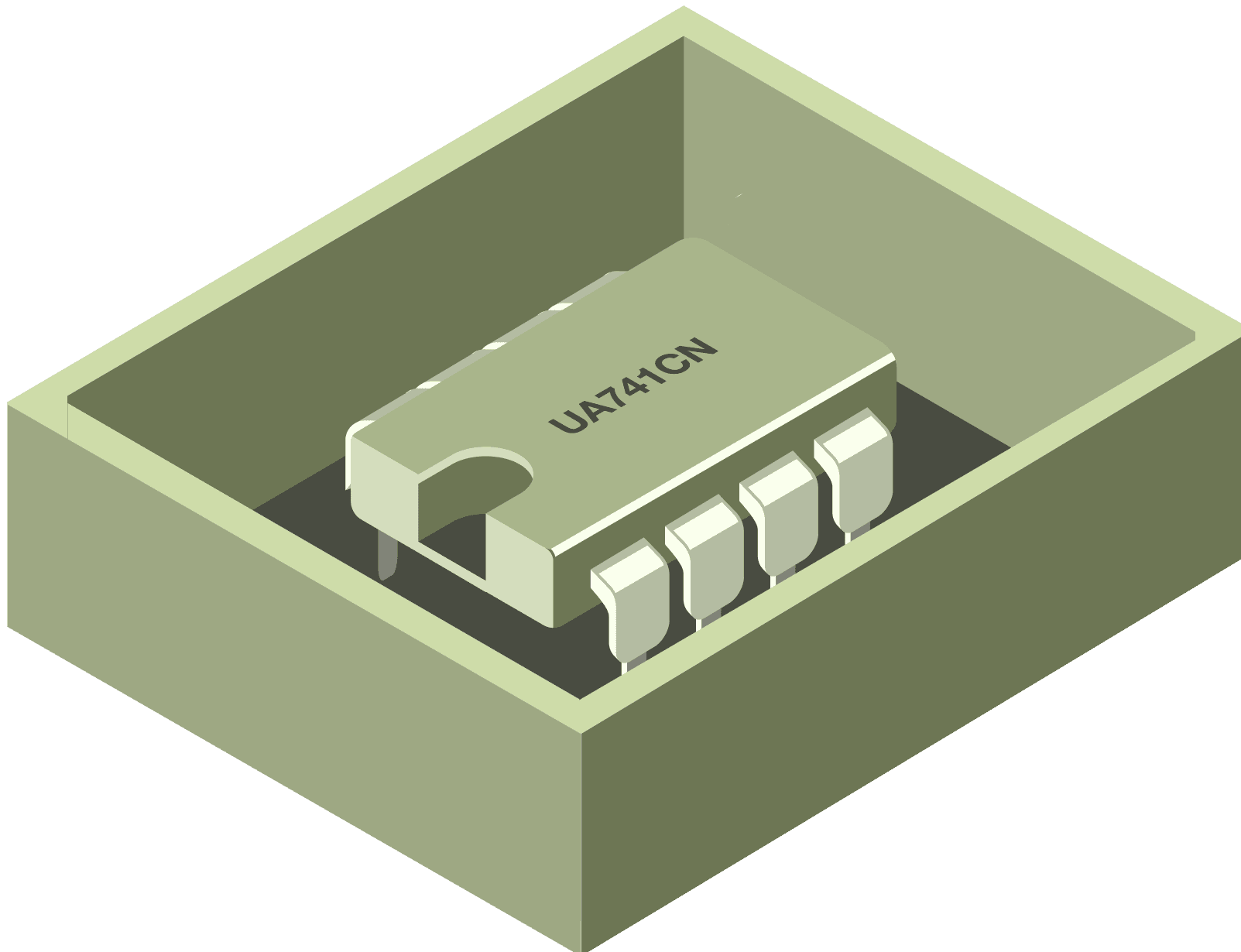

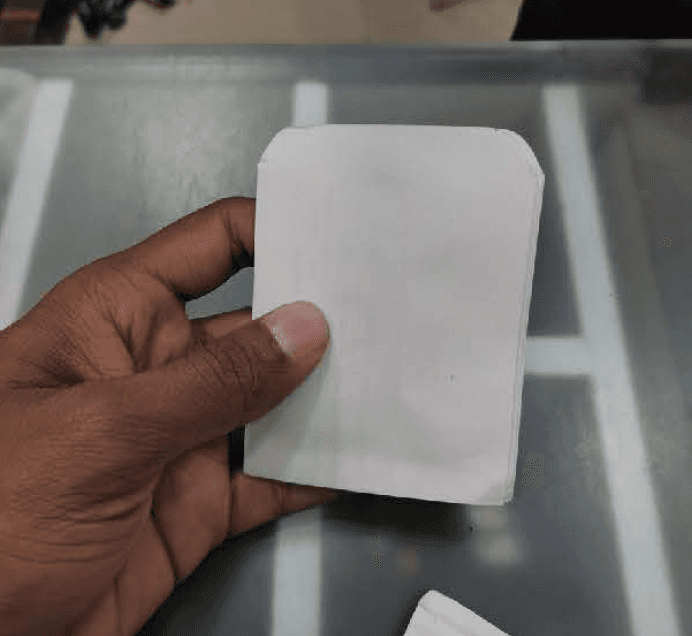

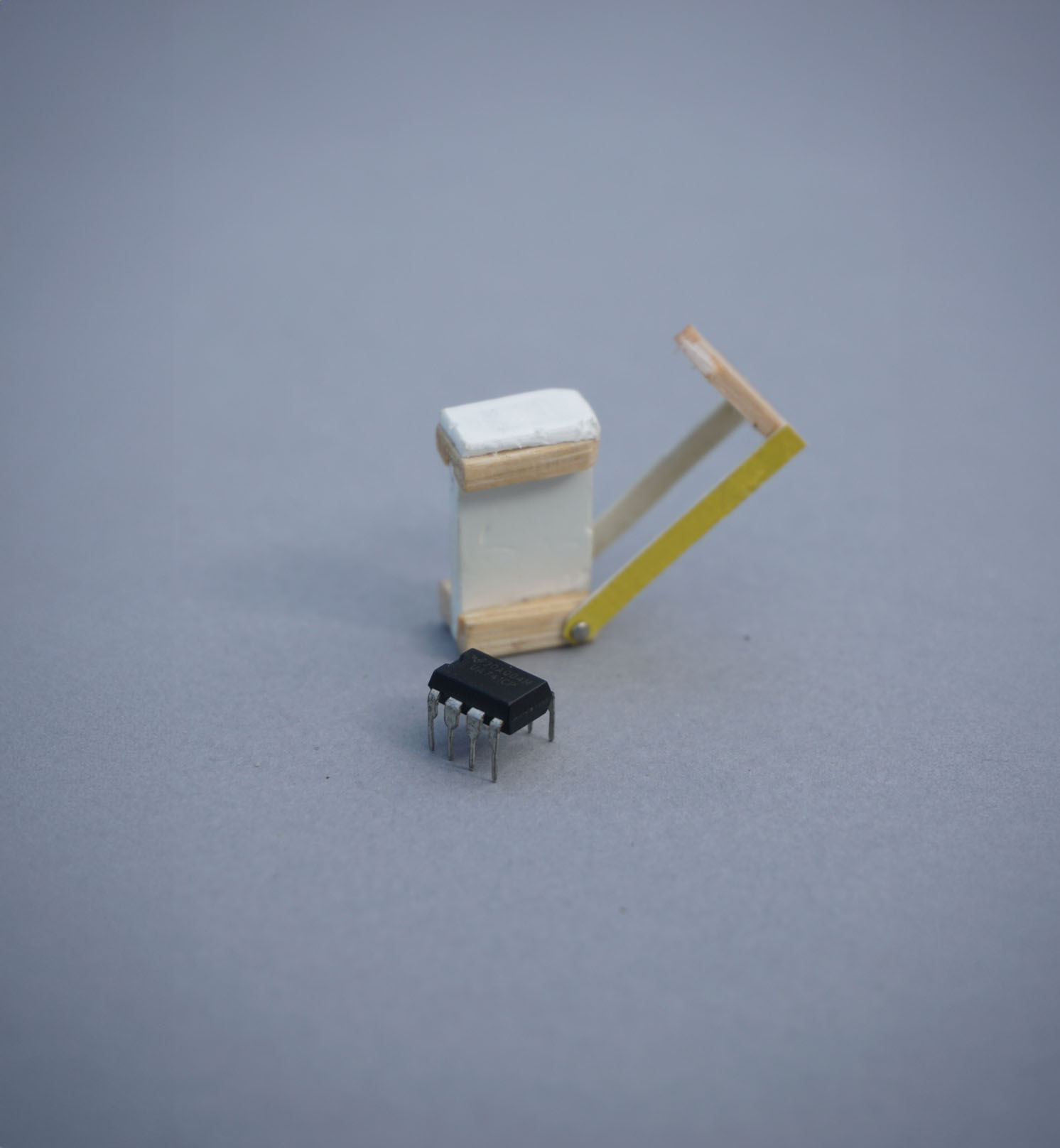

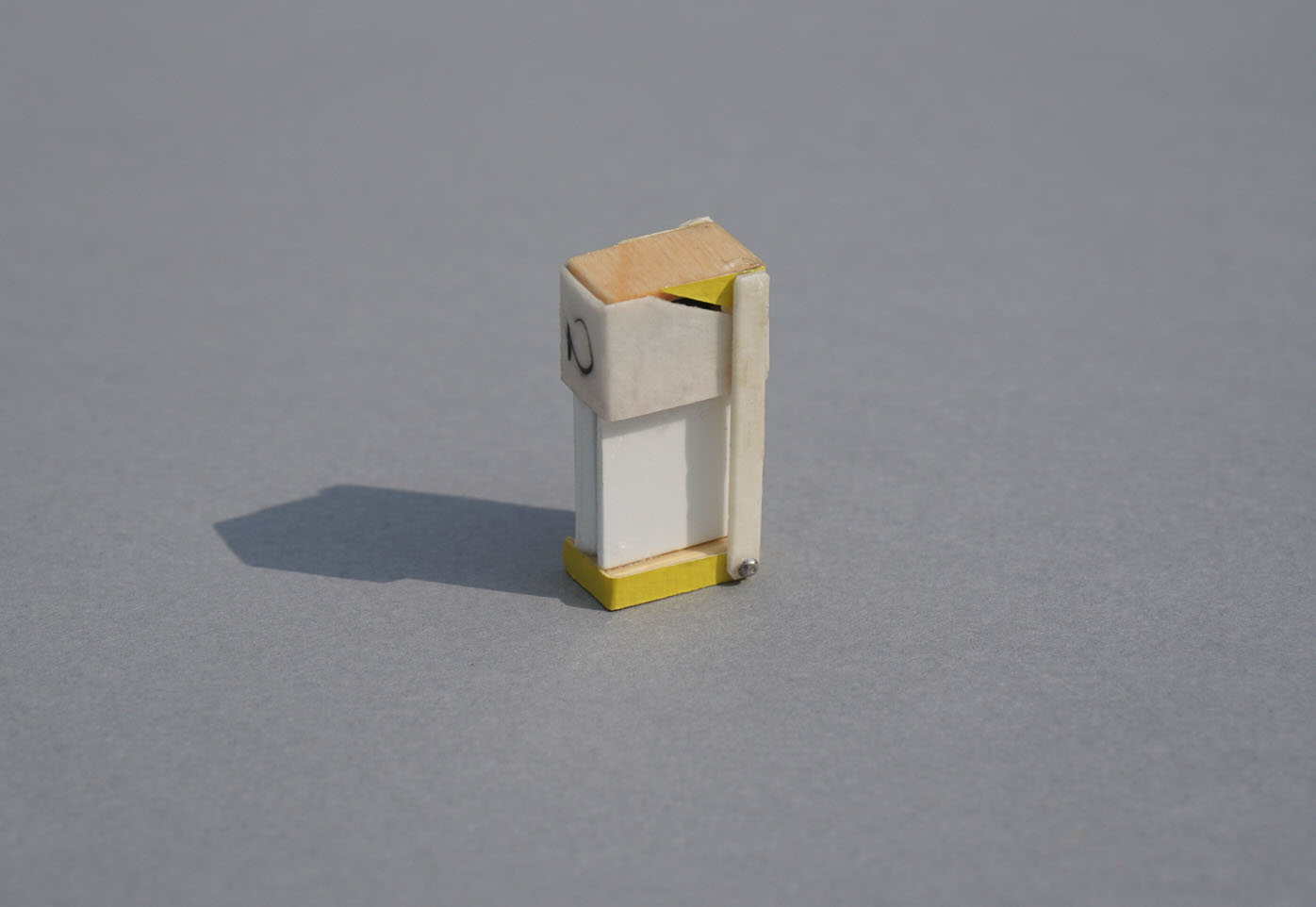

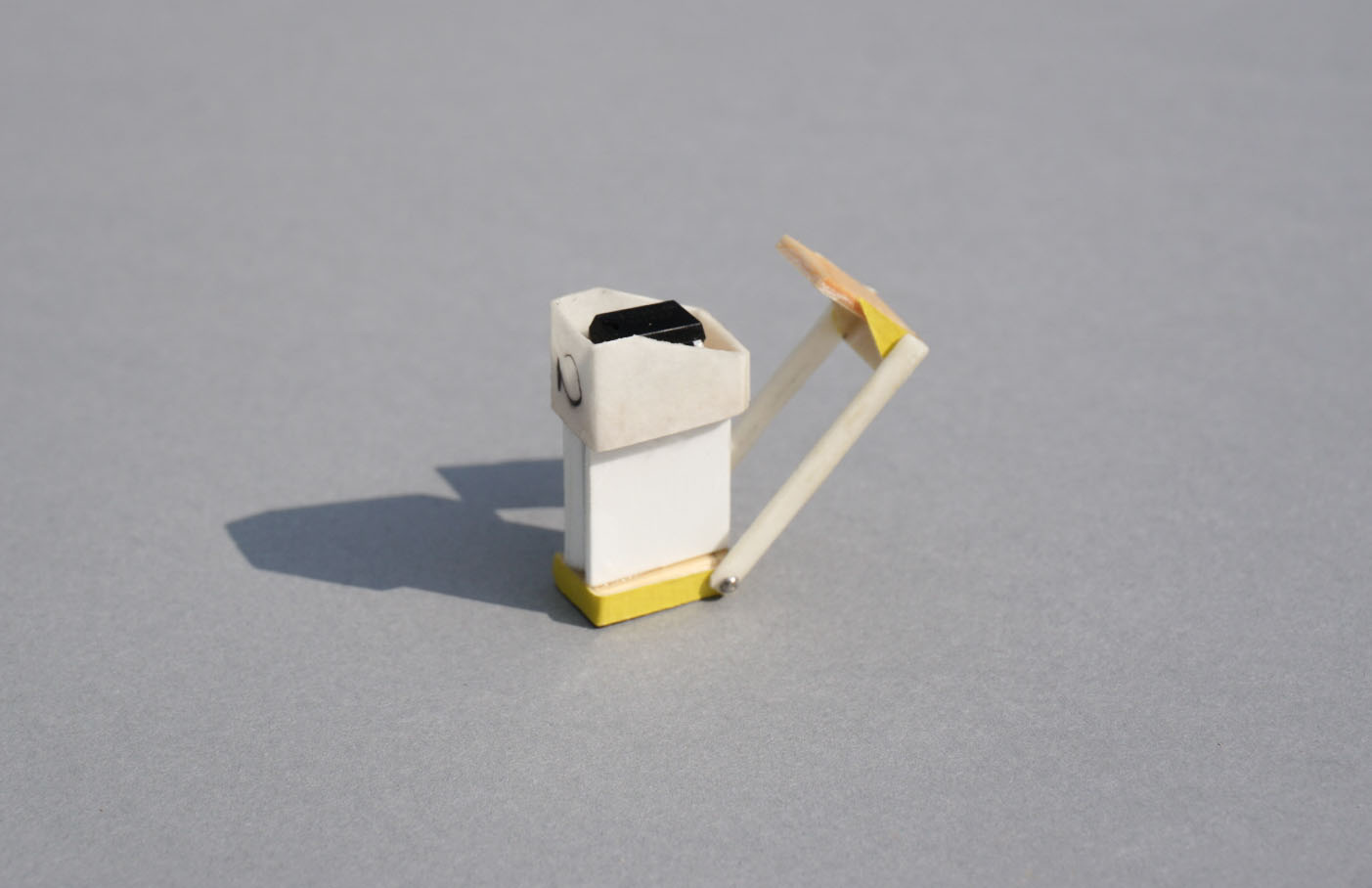

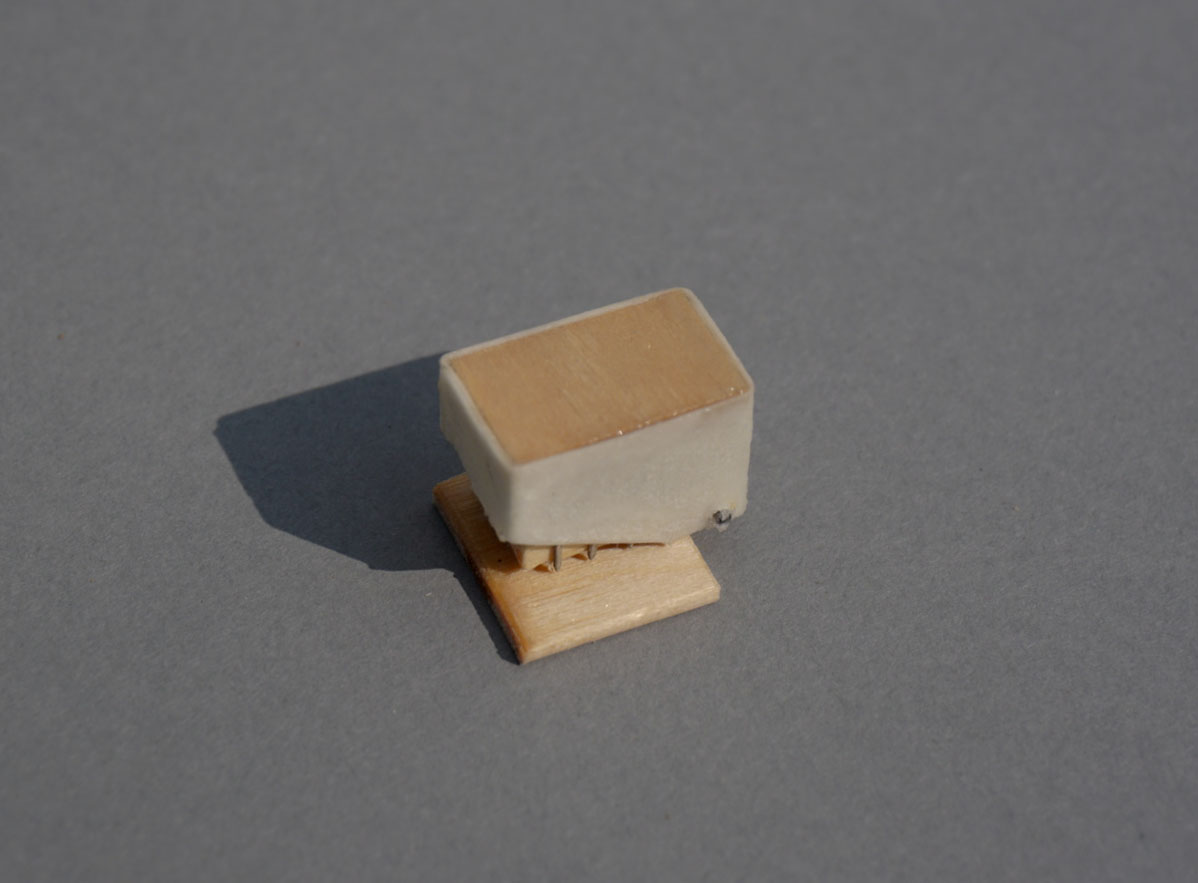

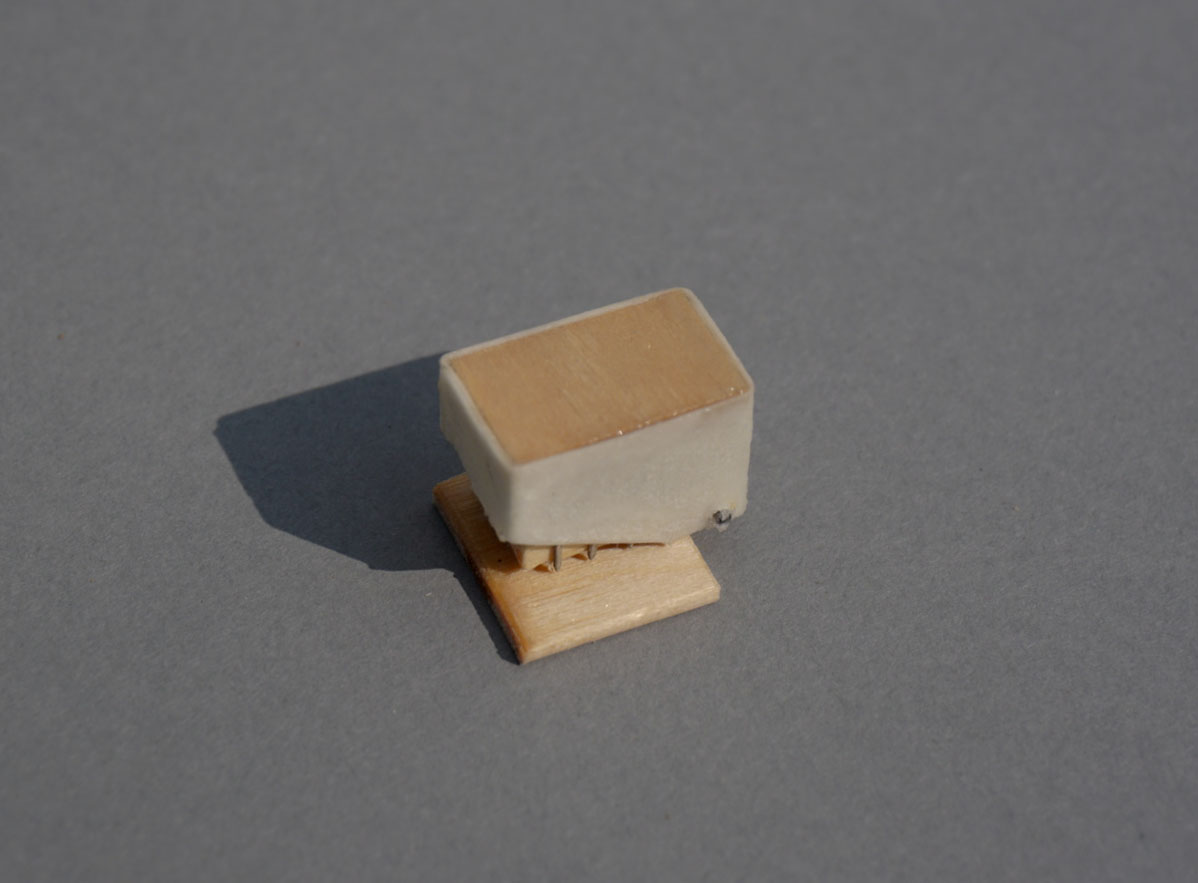

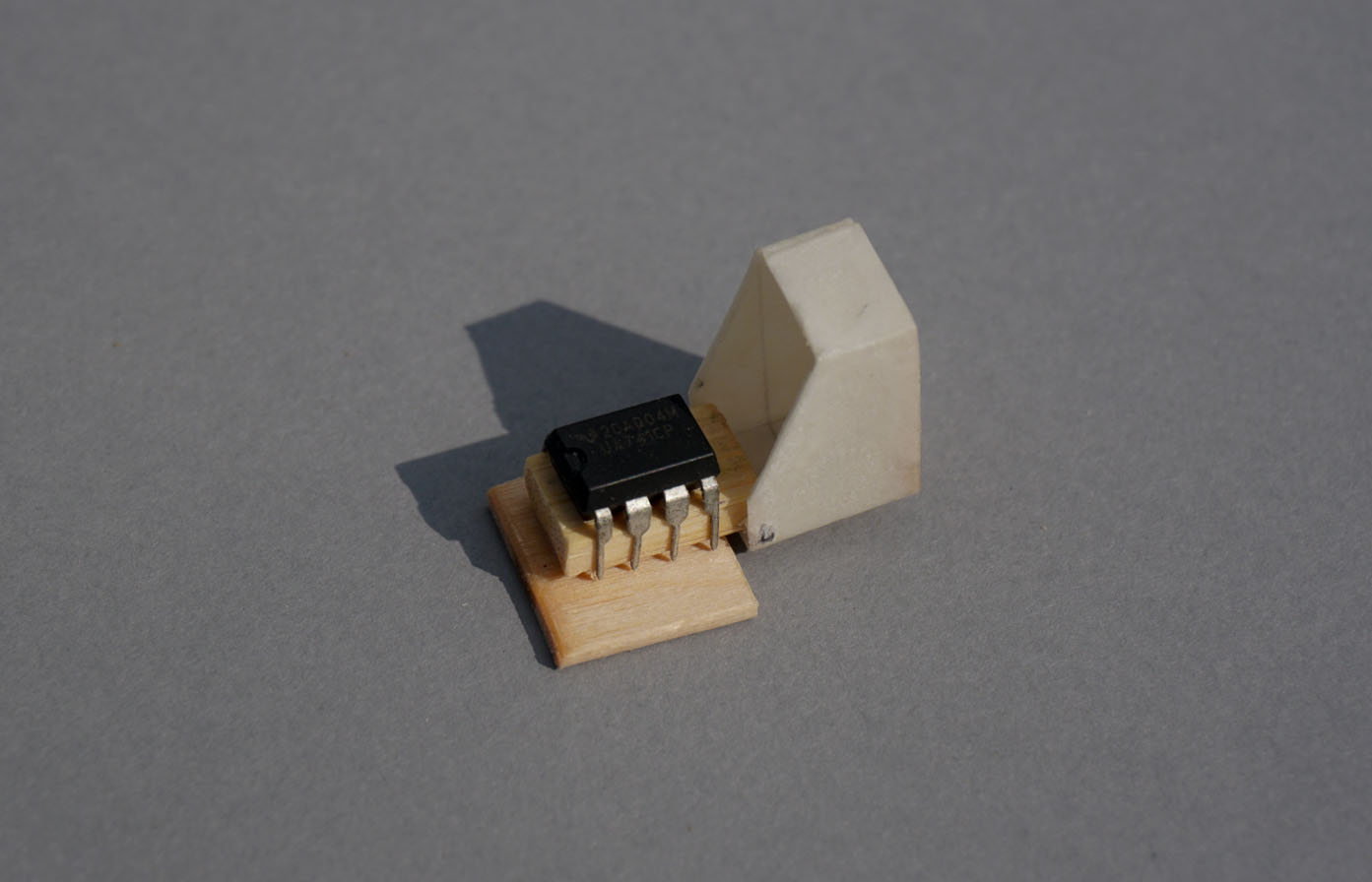

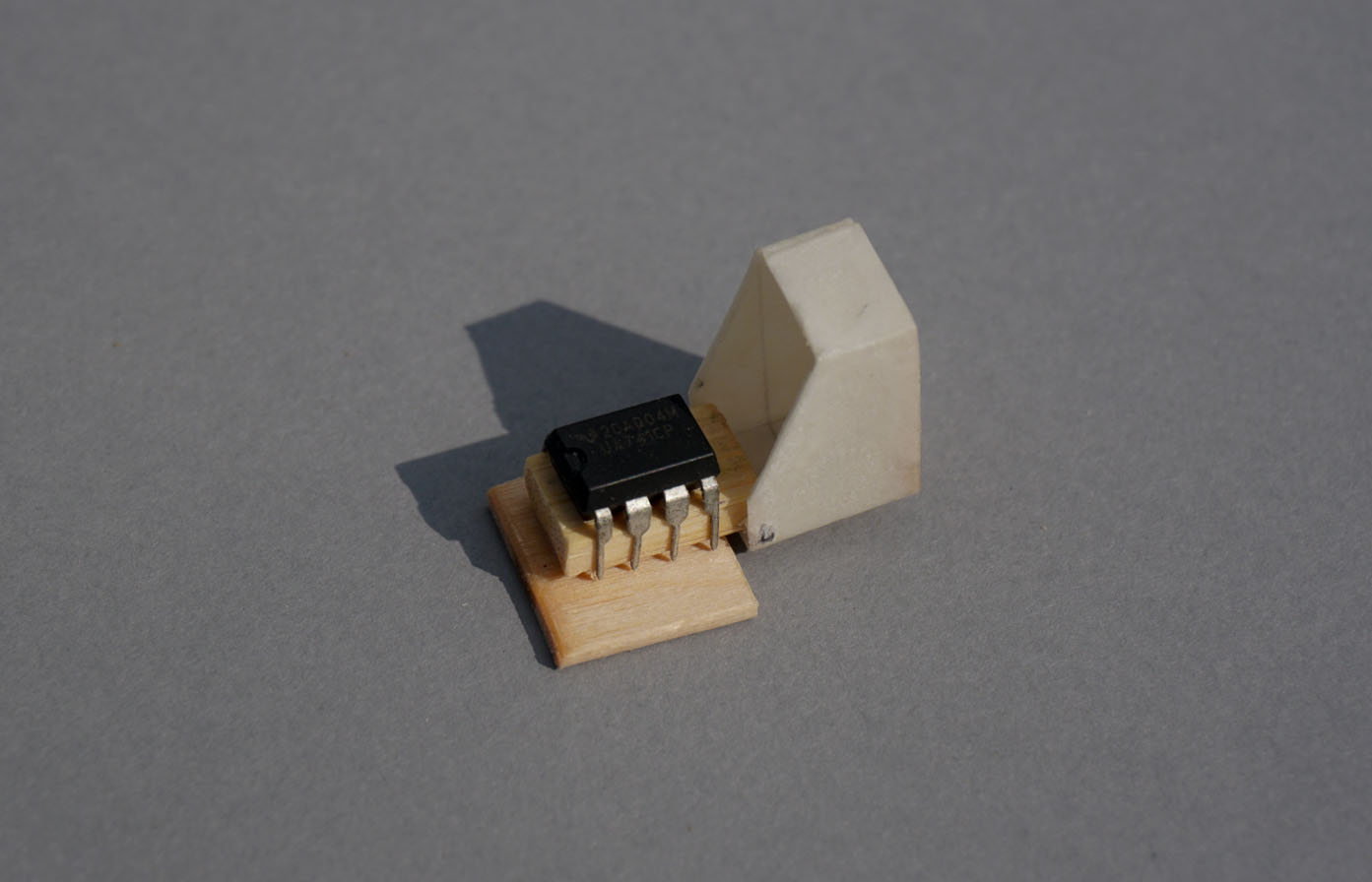

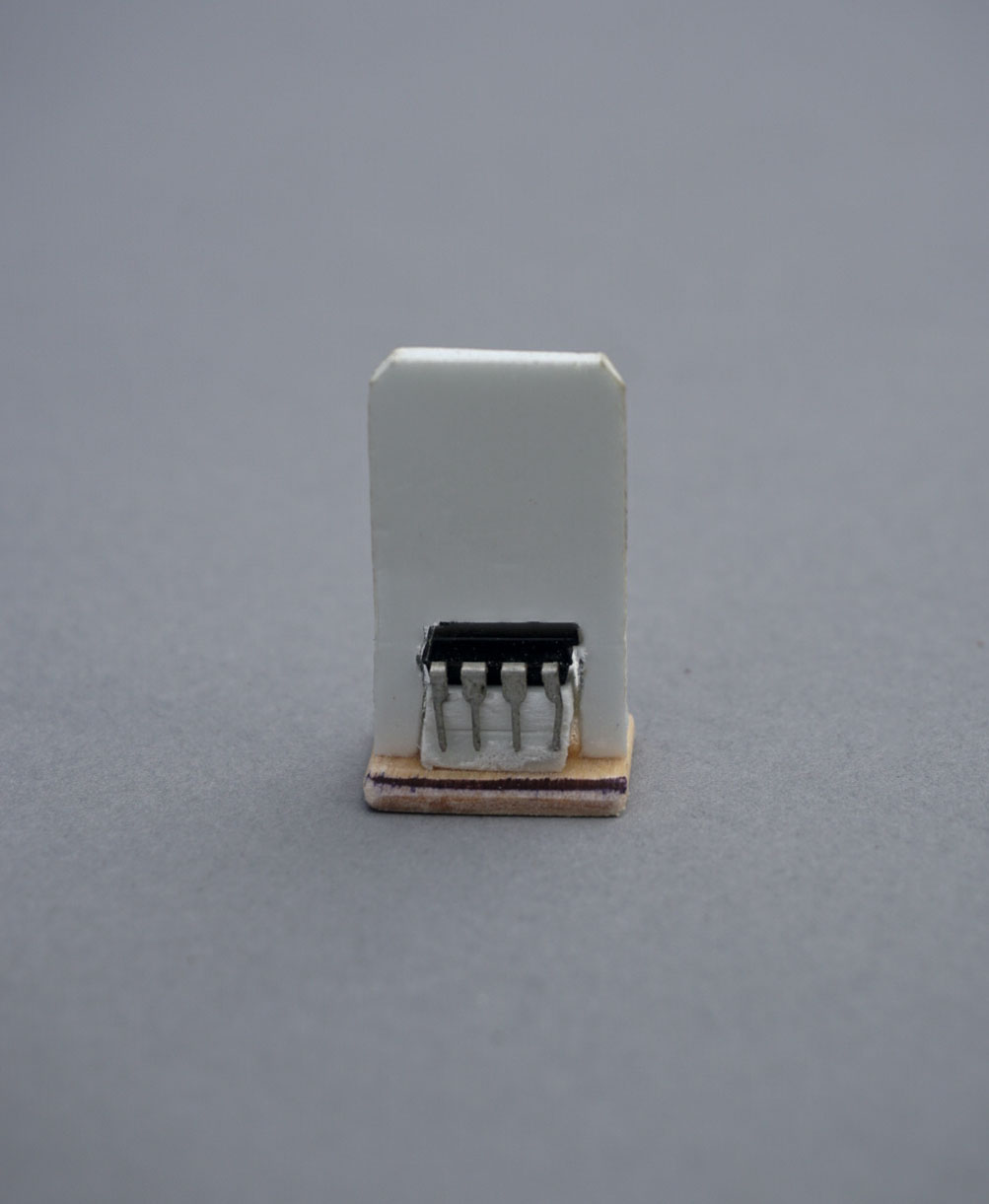

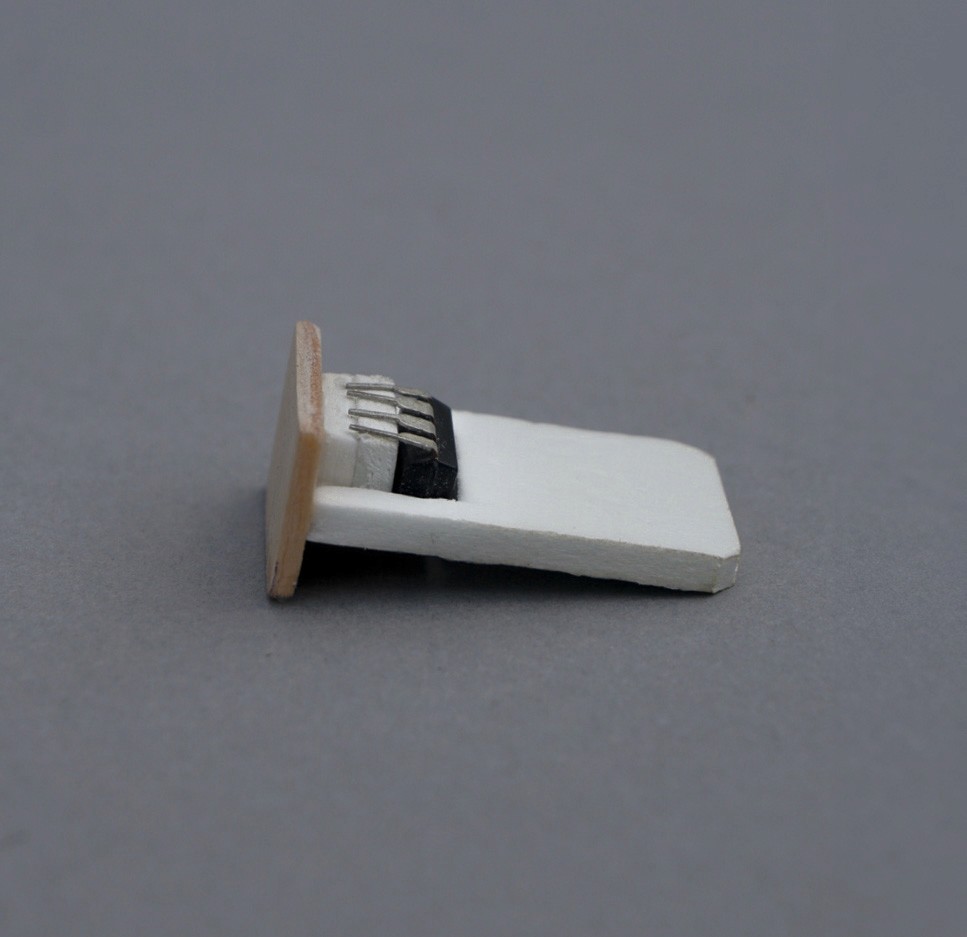

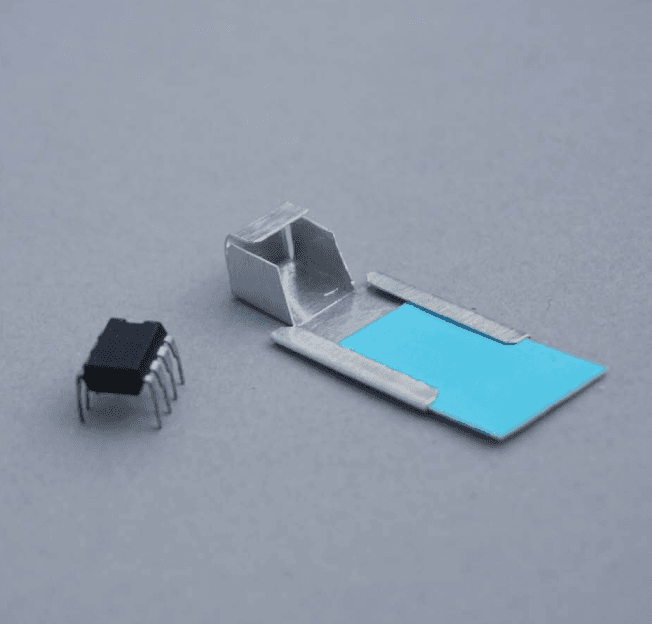

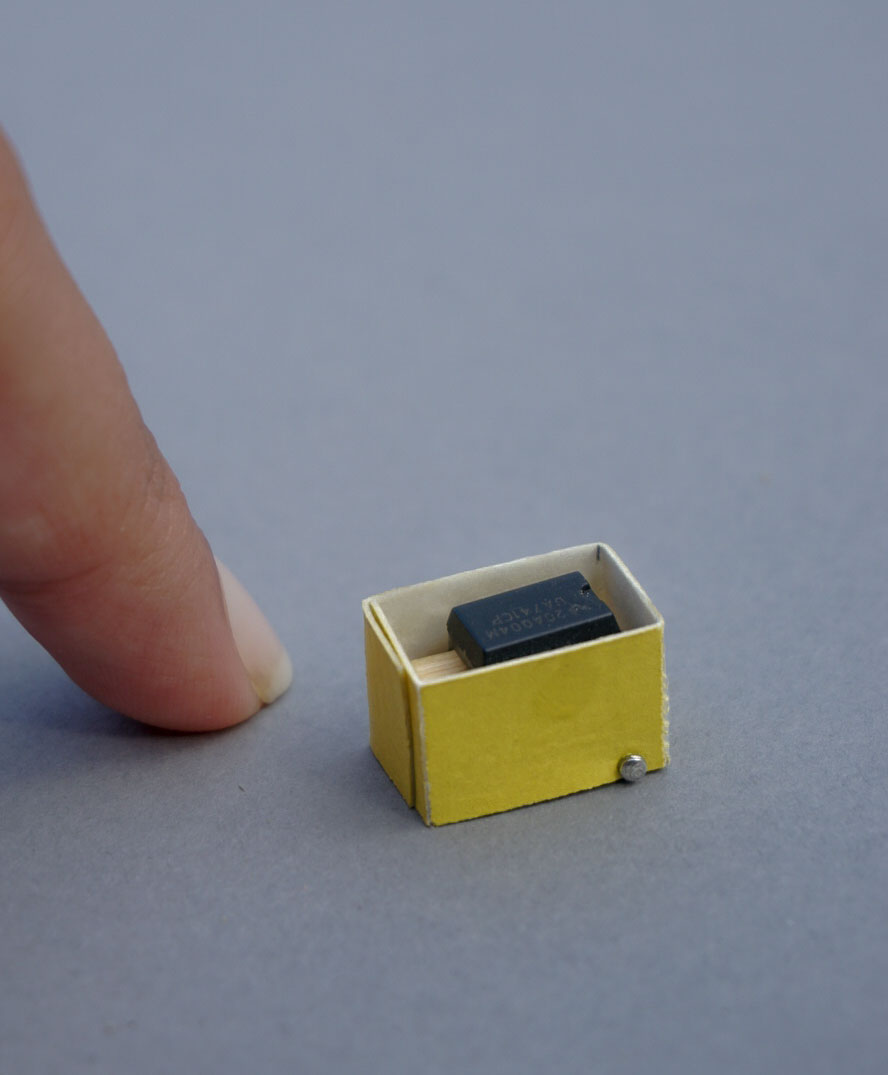

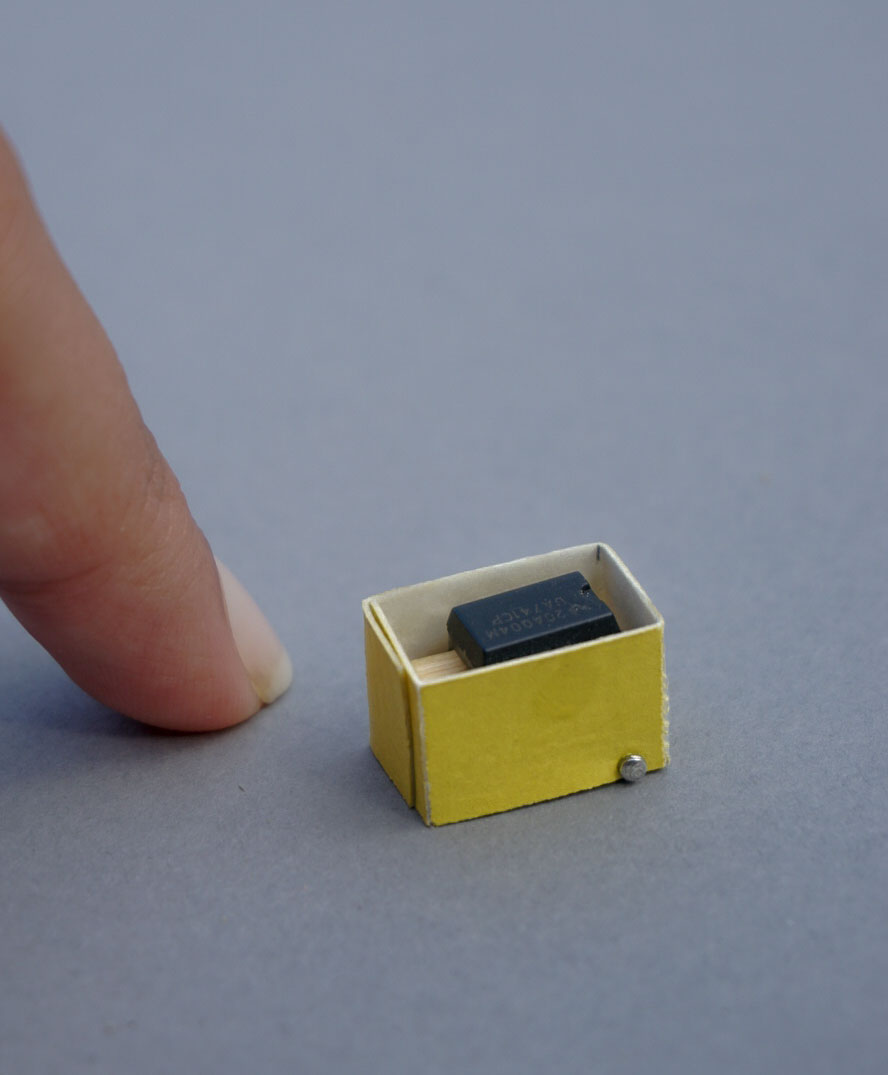

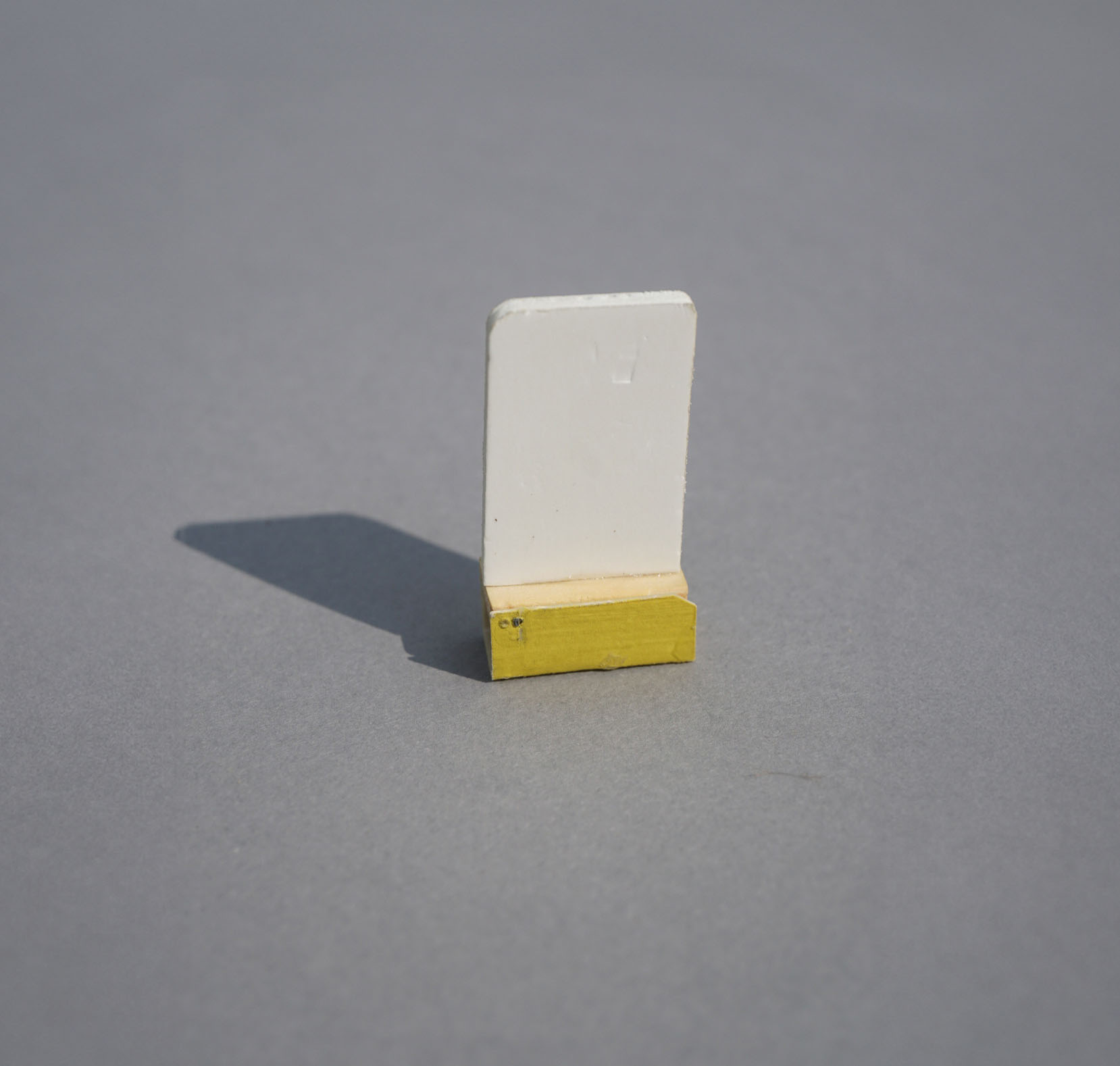

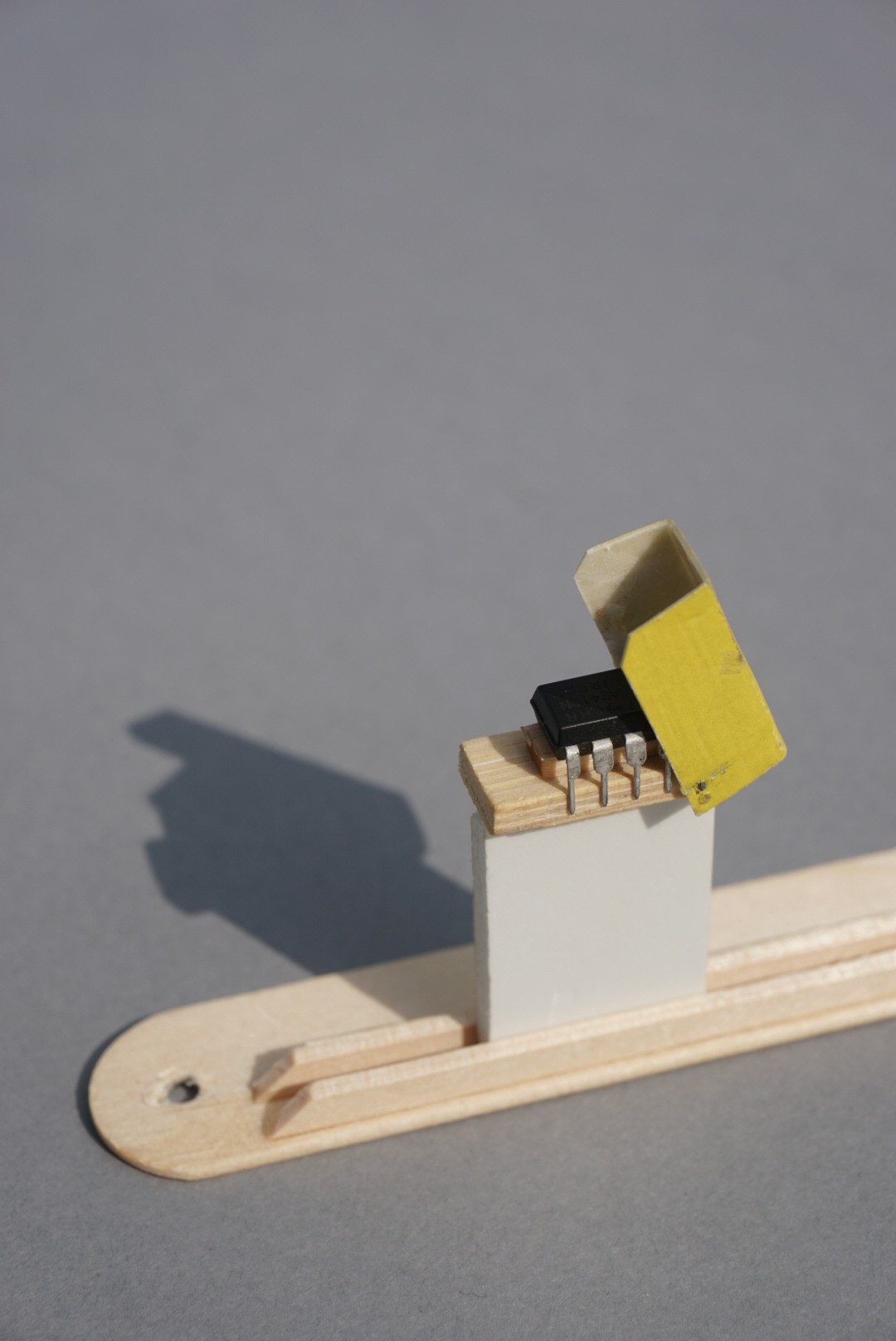

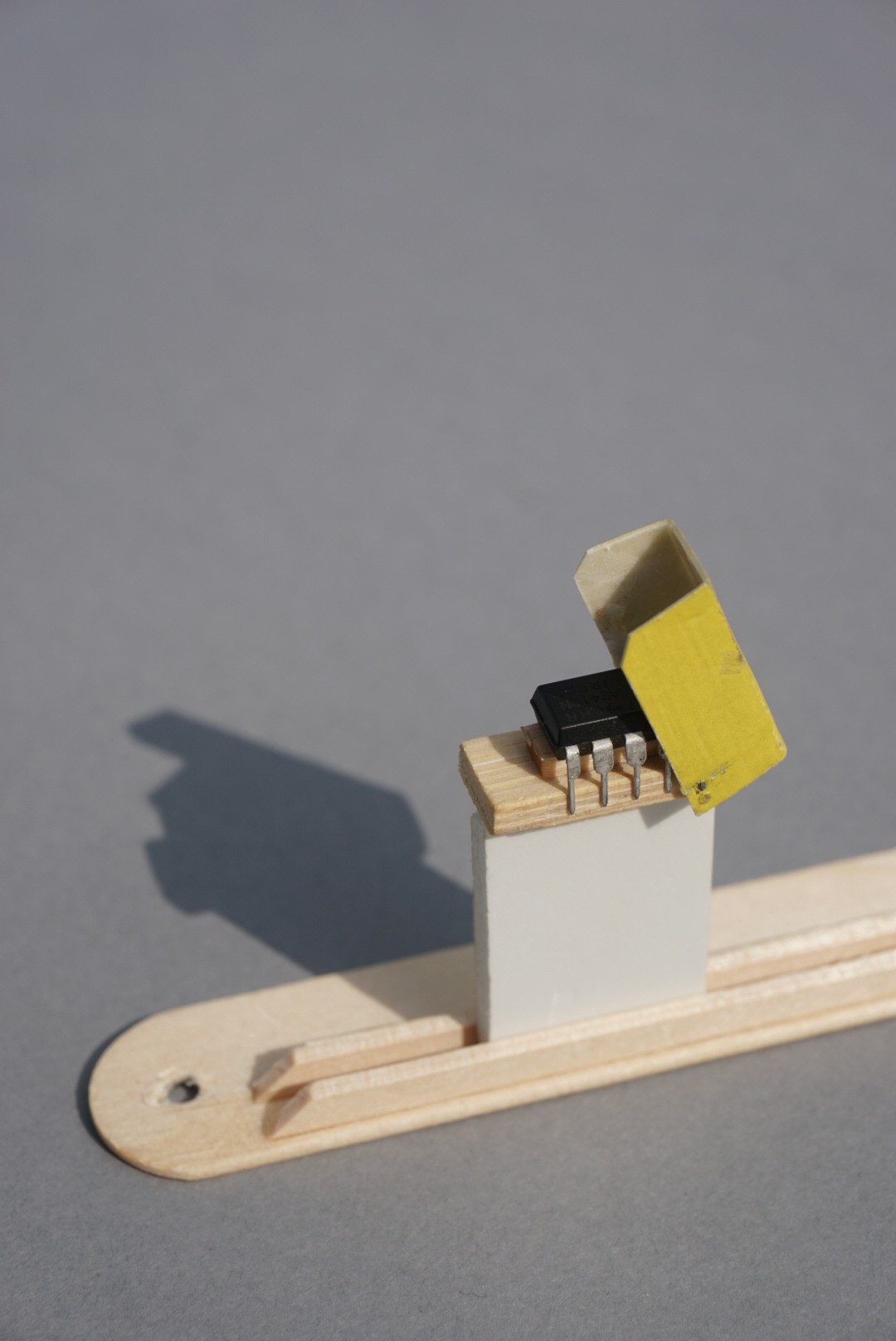

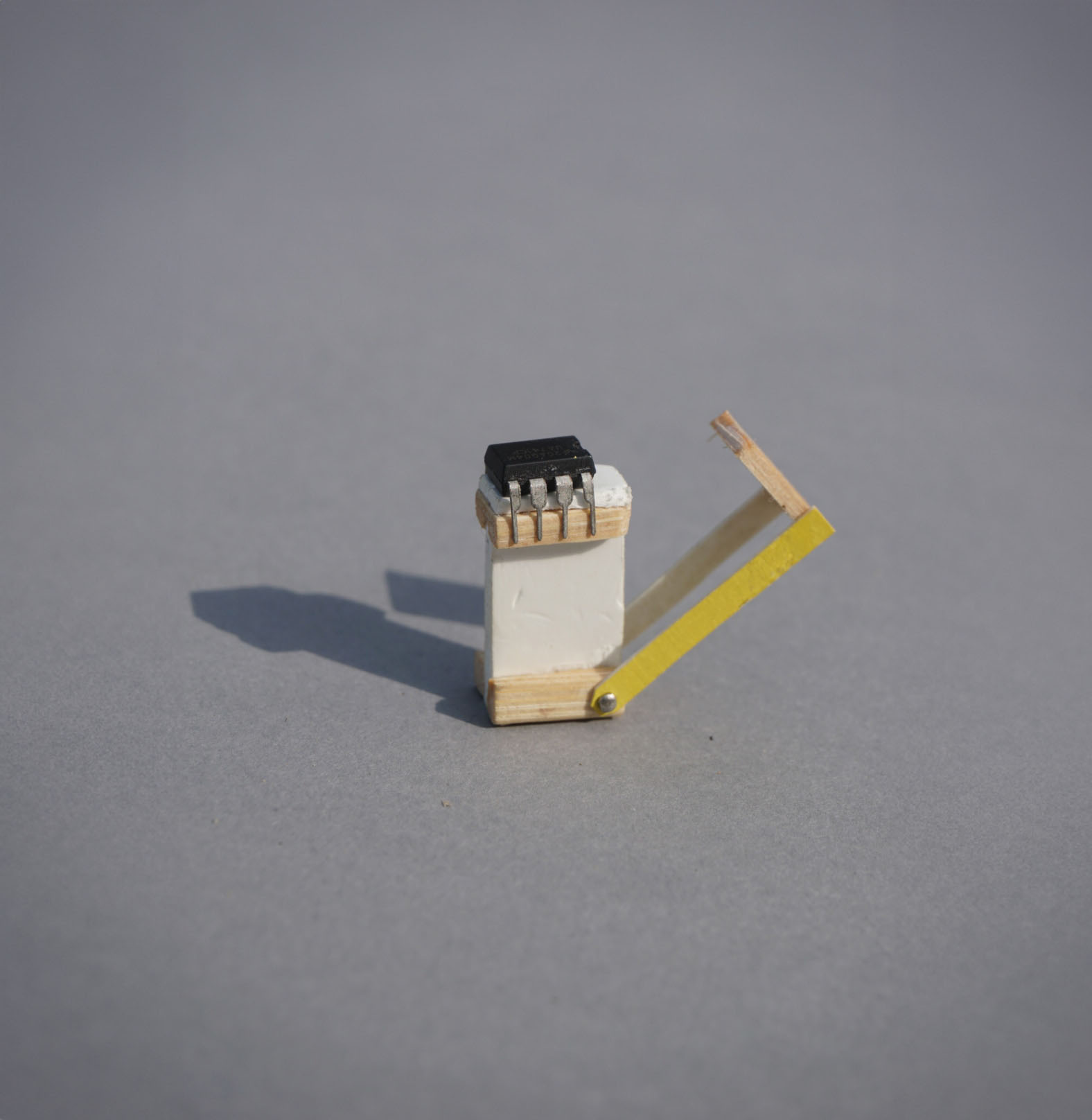

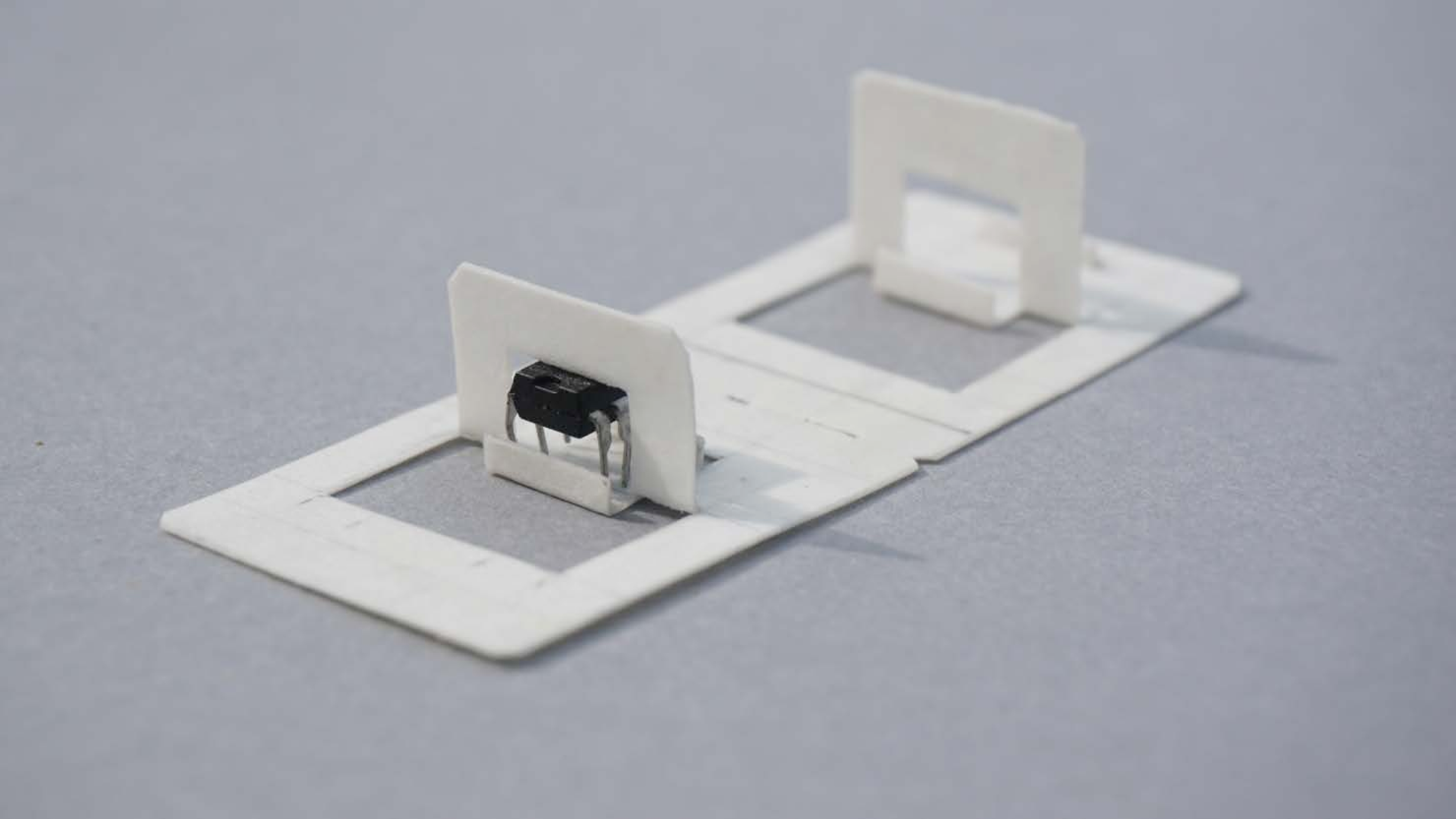

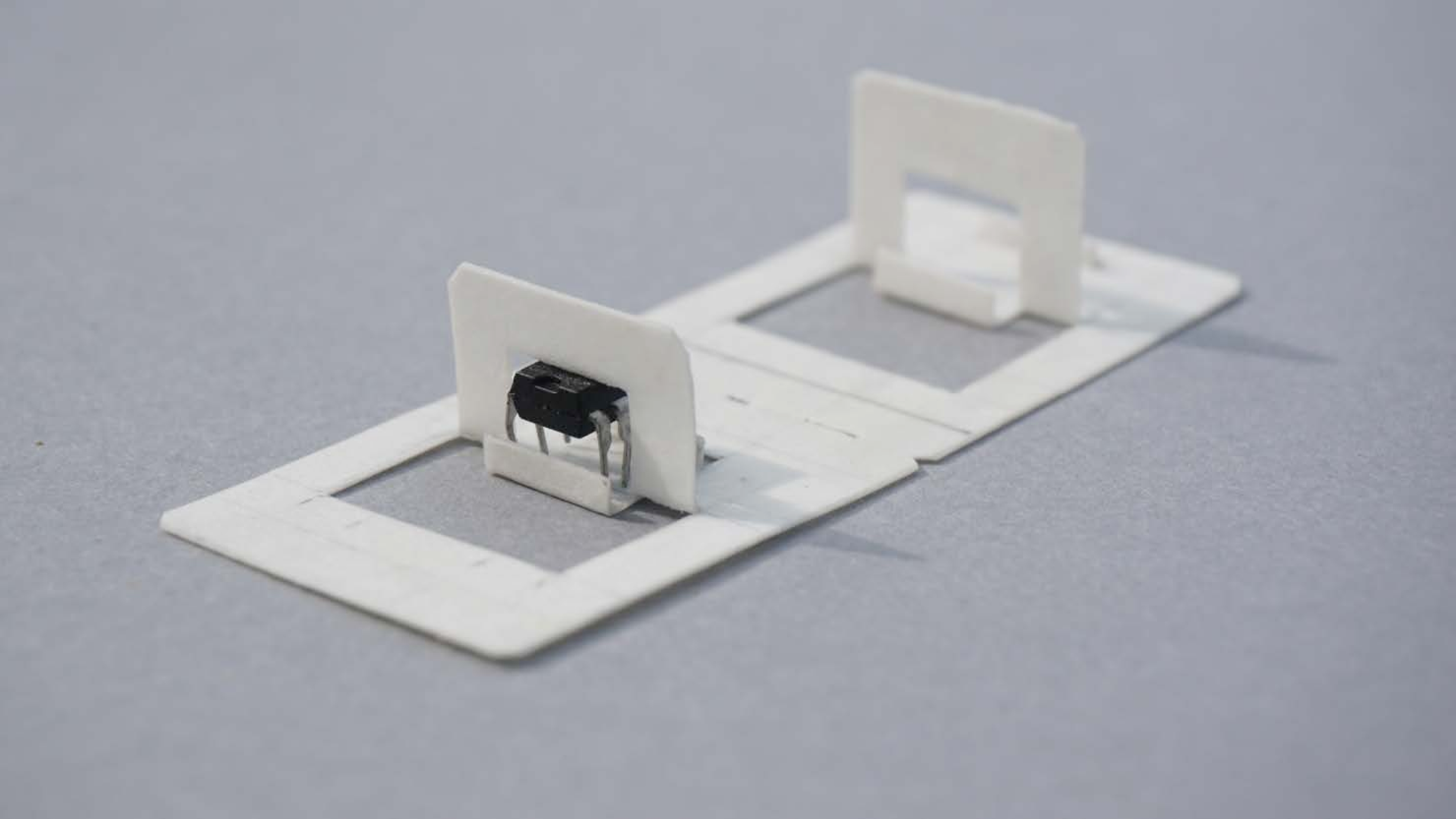

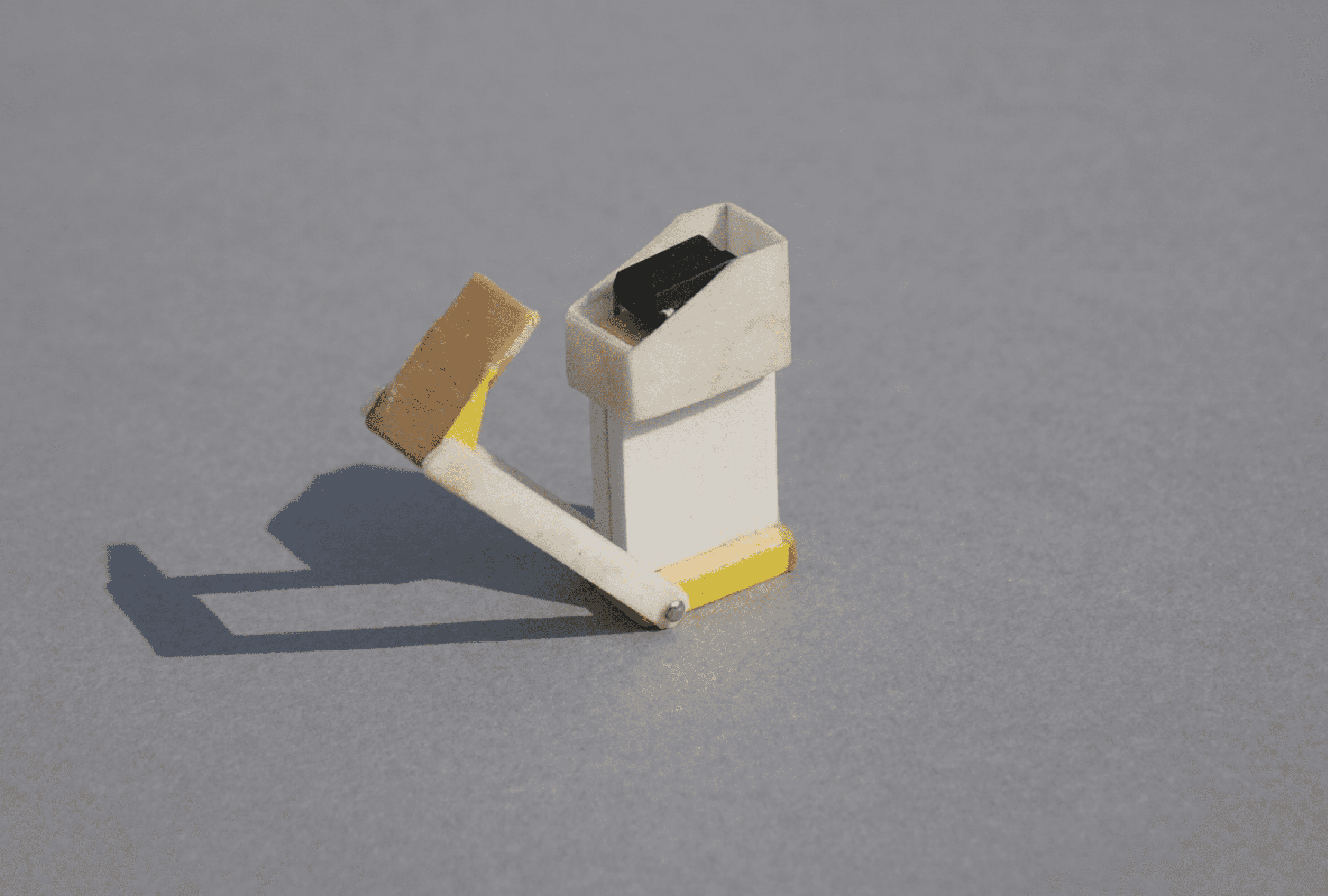

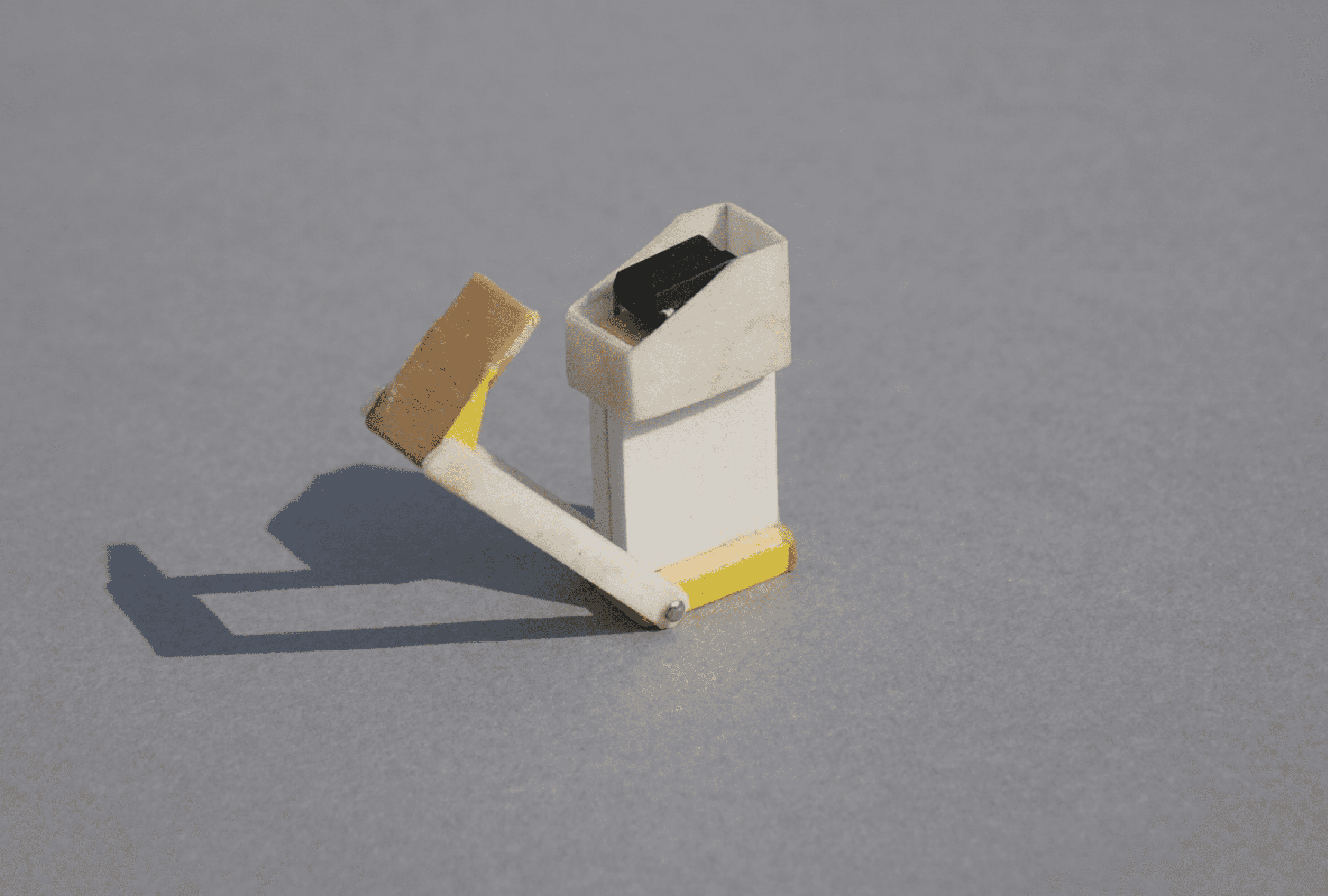

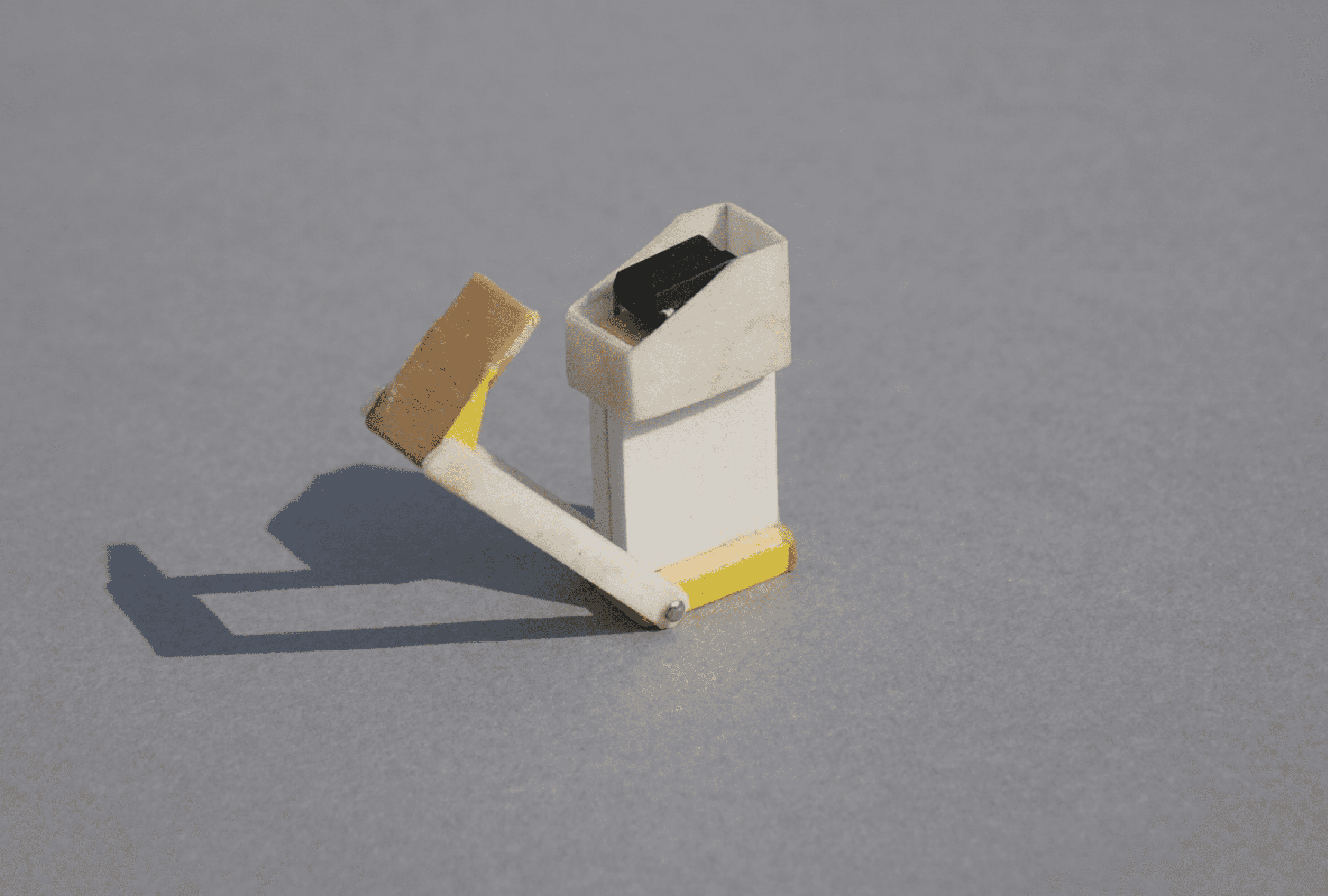

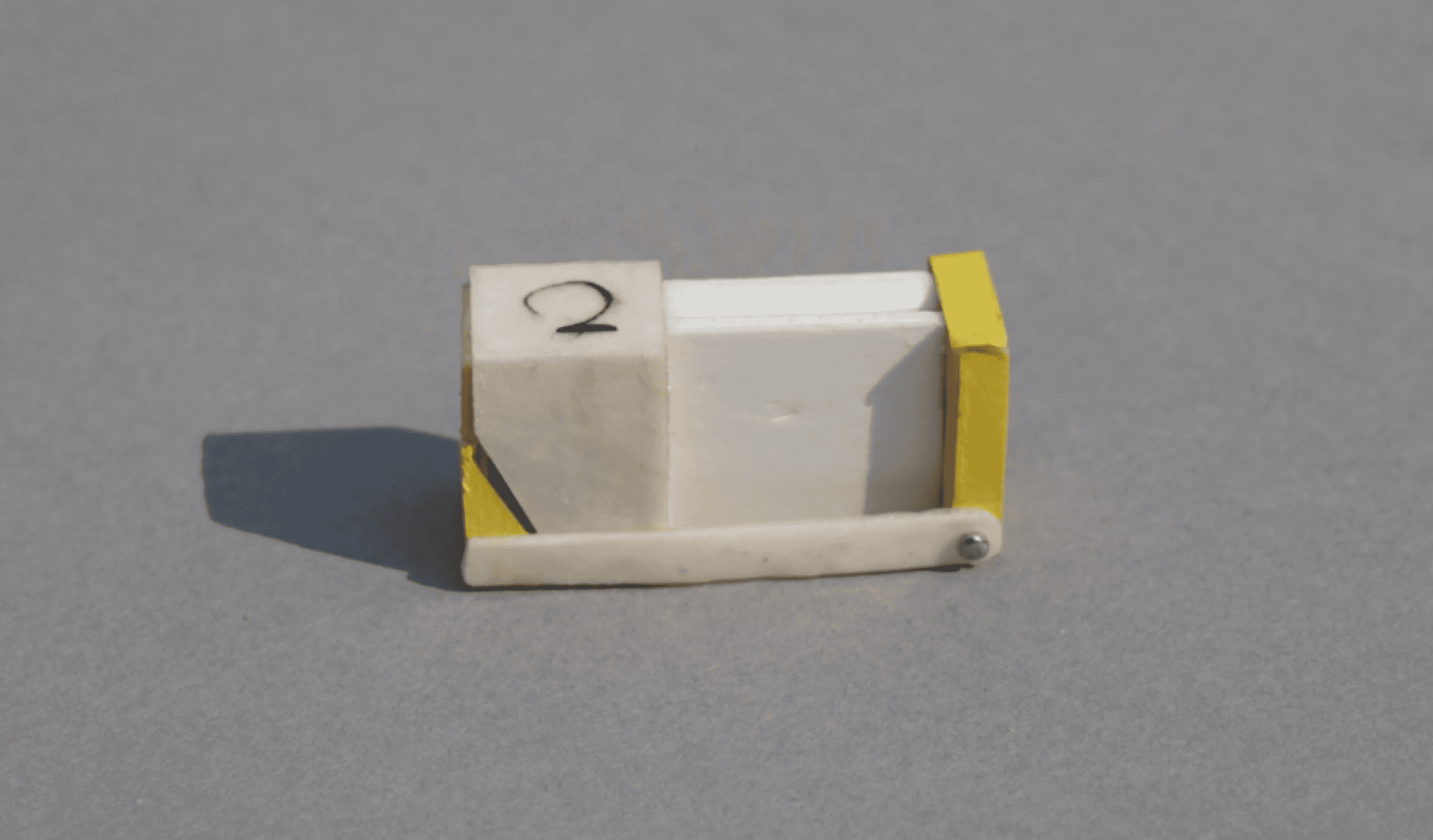

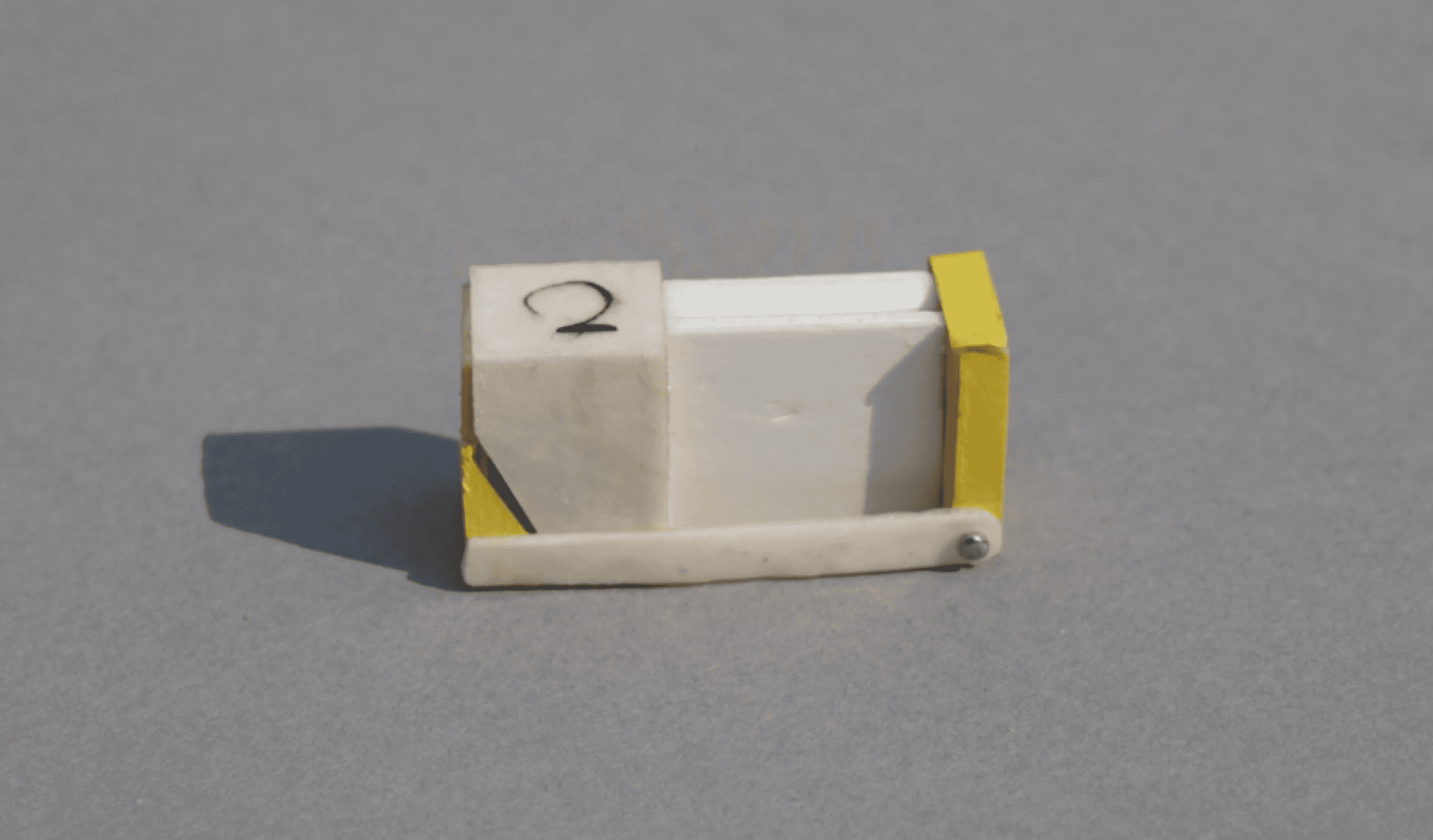

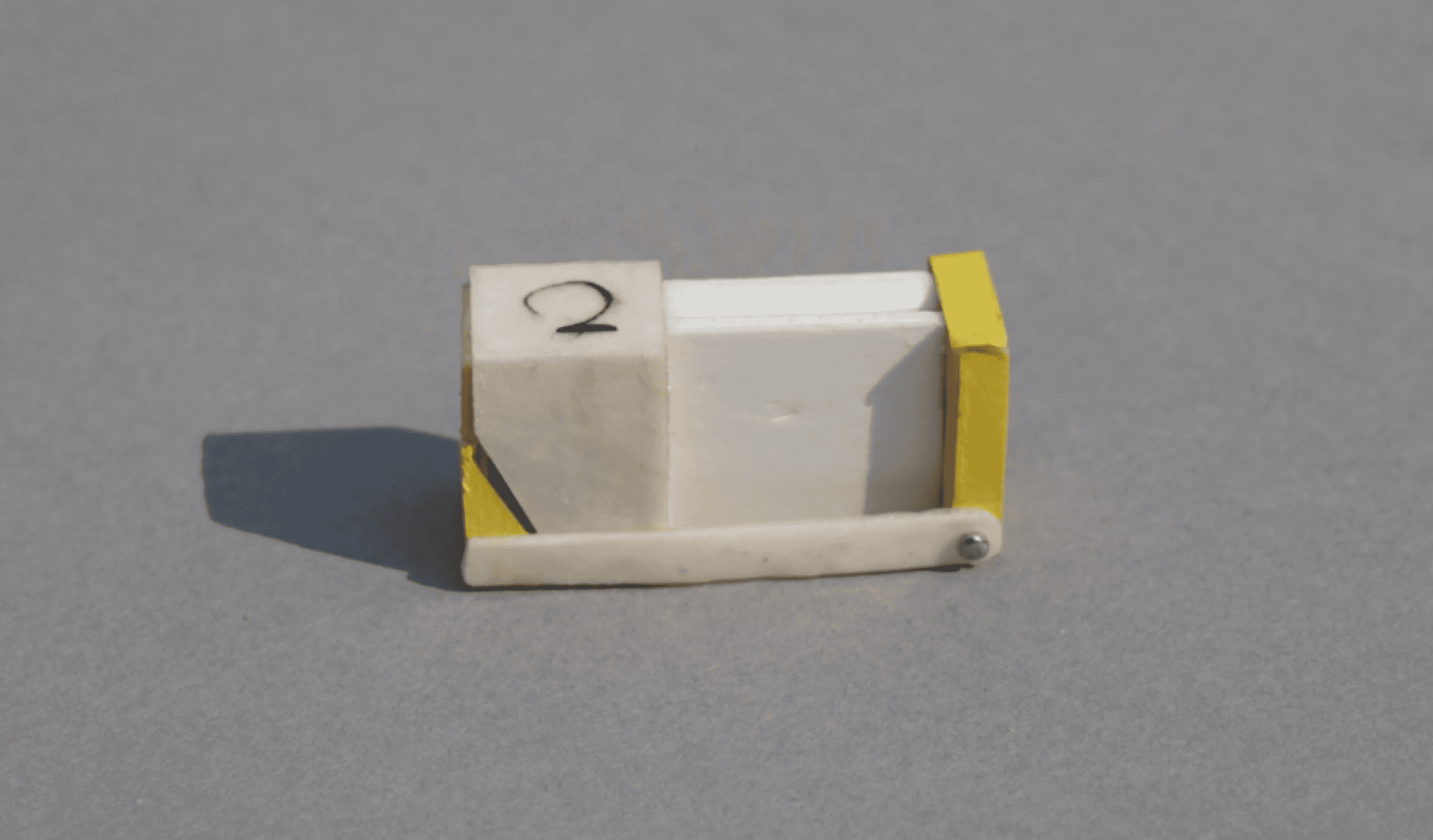

This prototype was finalized for its

small size, efficiency and functional

reliability.

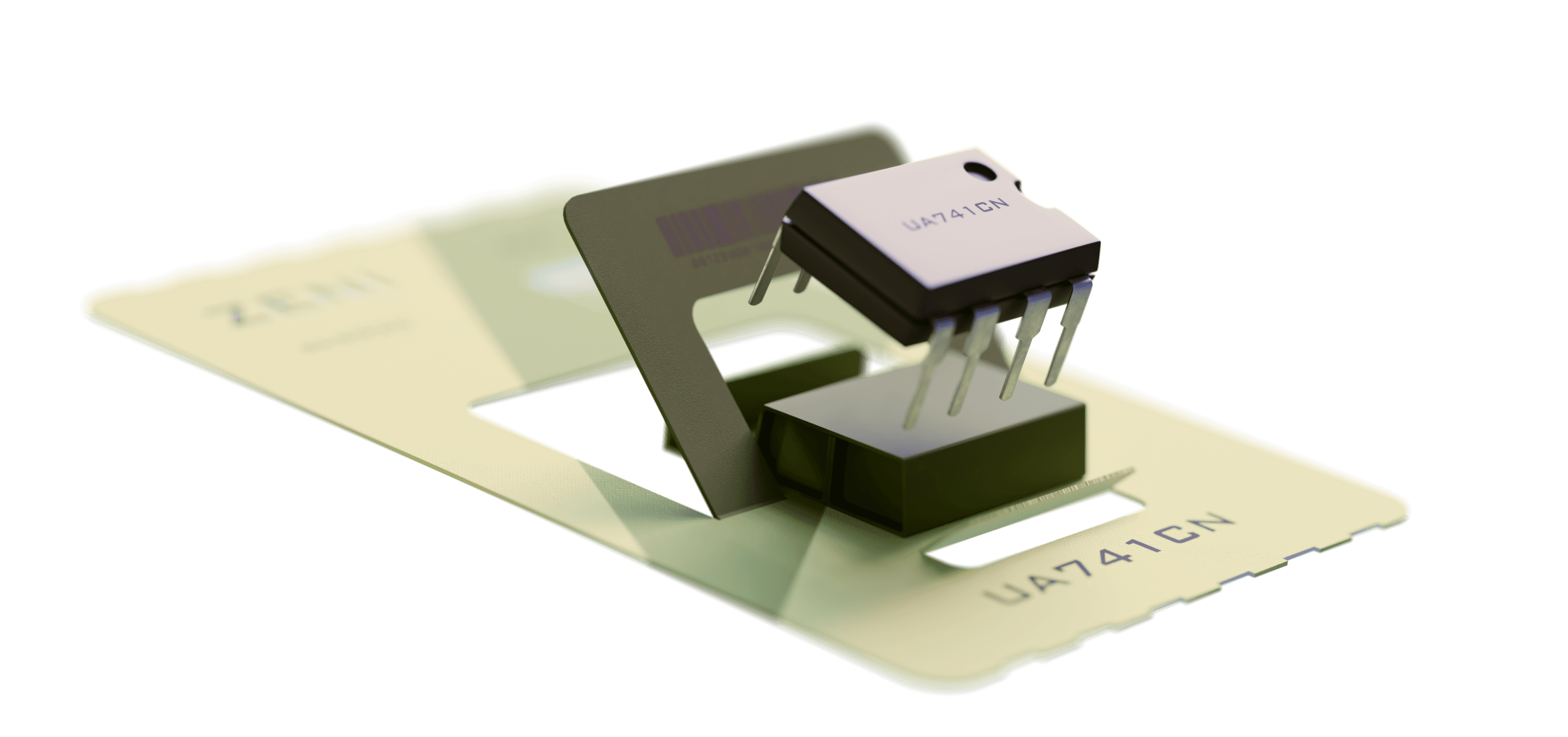

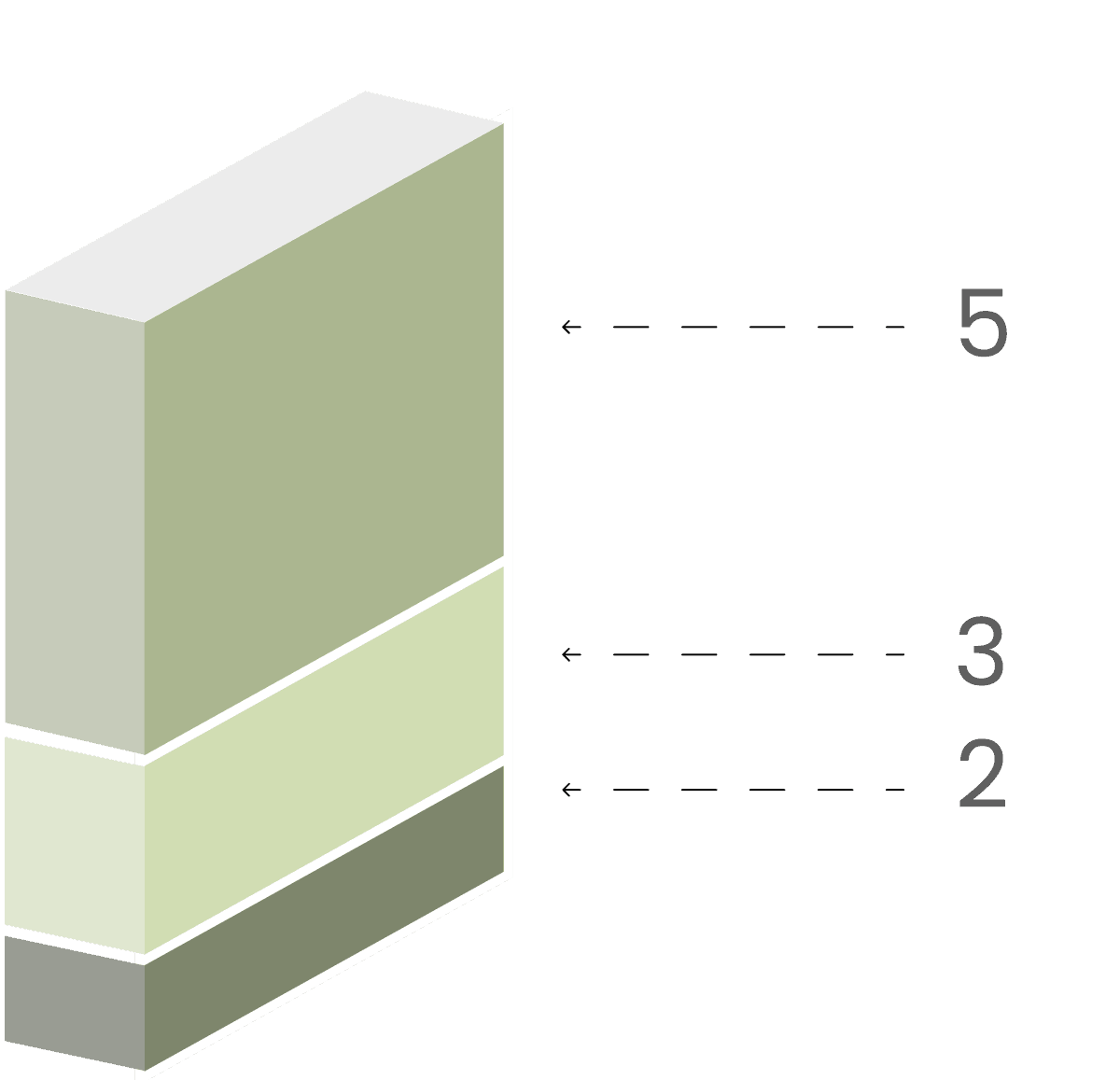

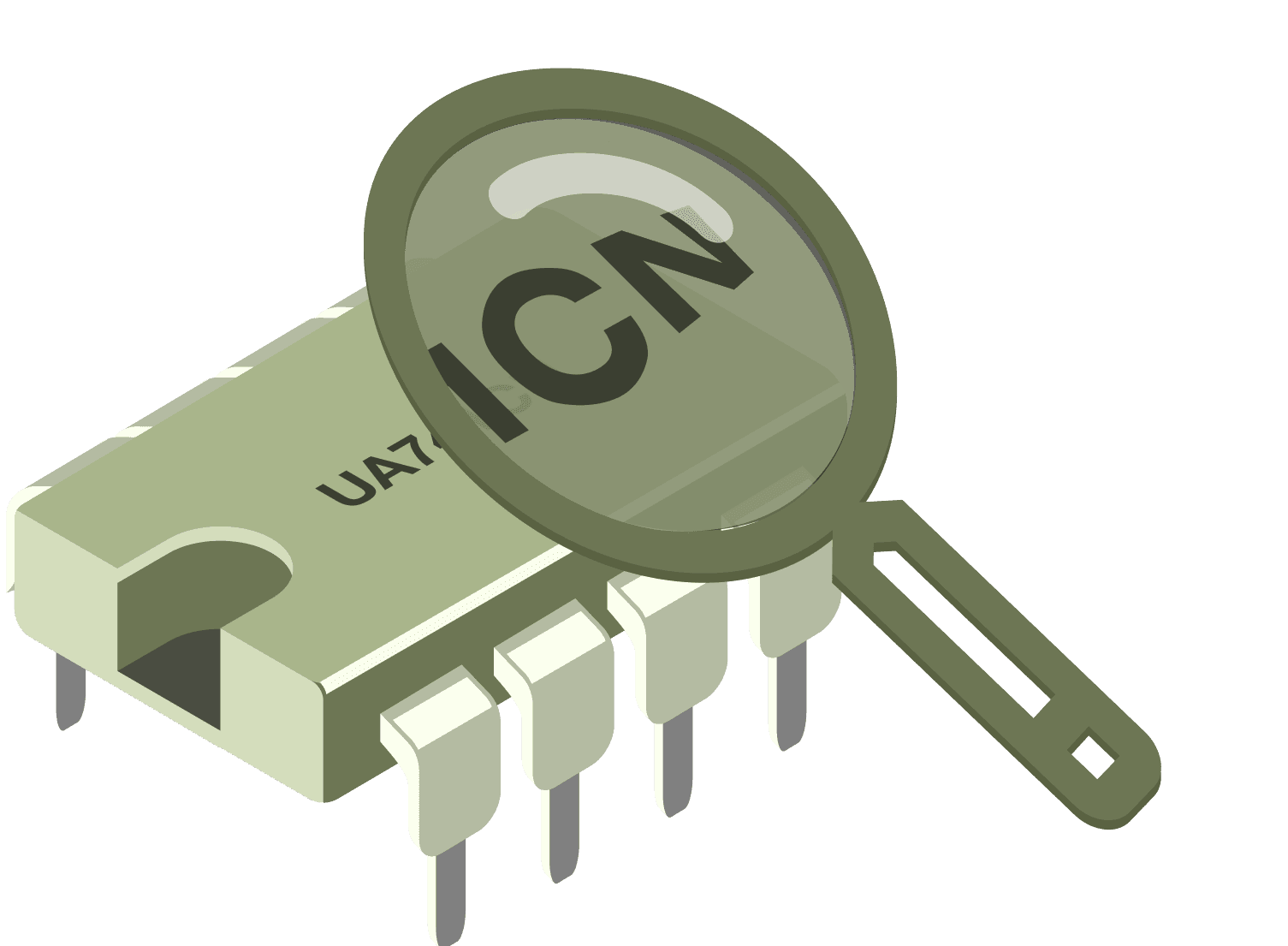

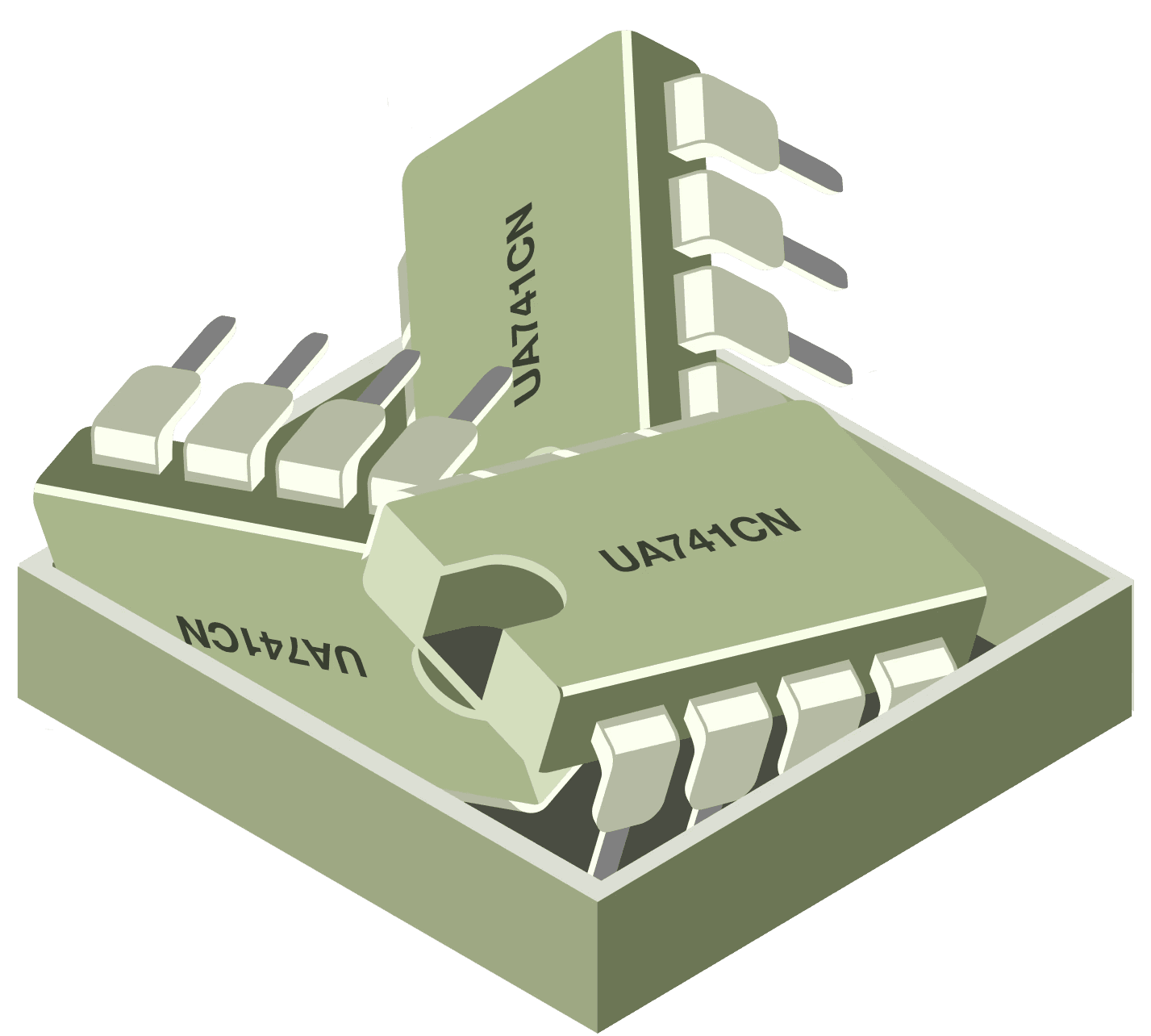

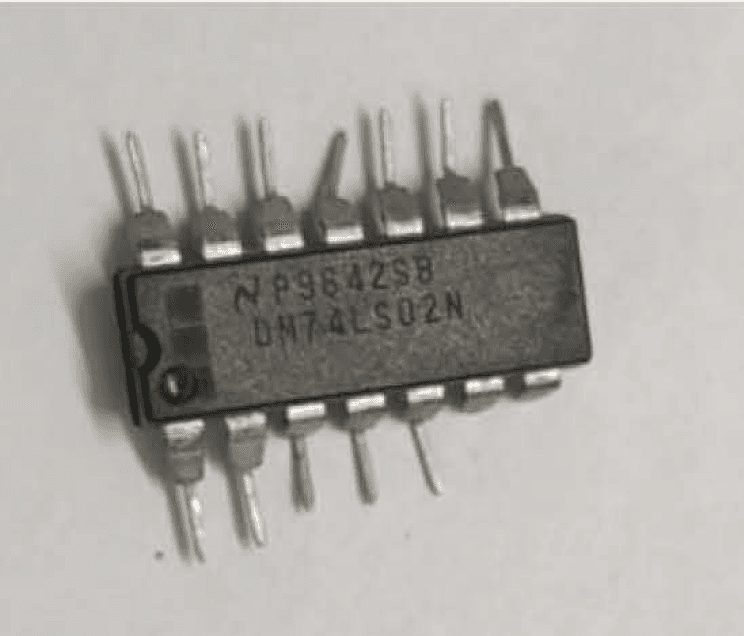

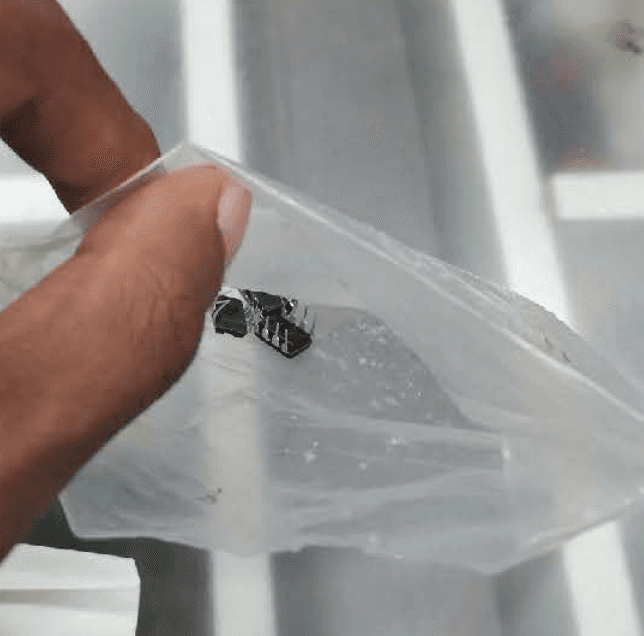

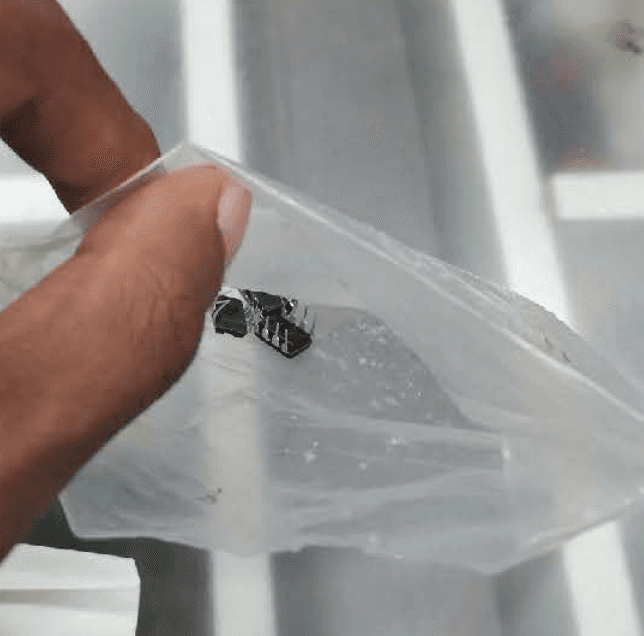

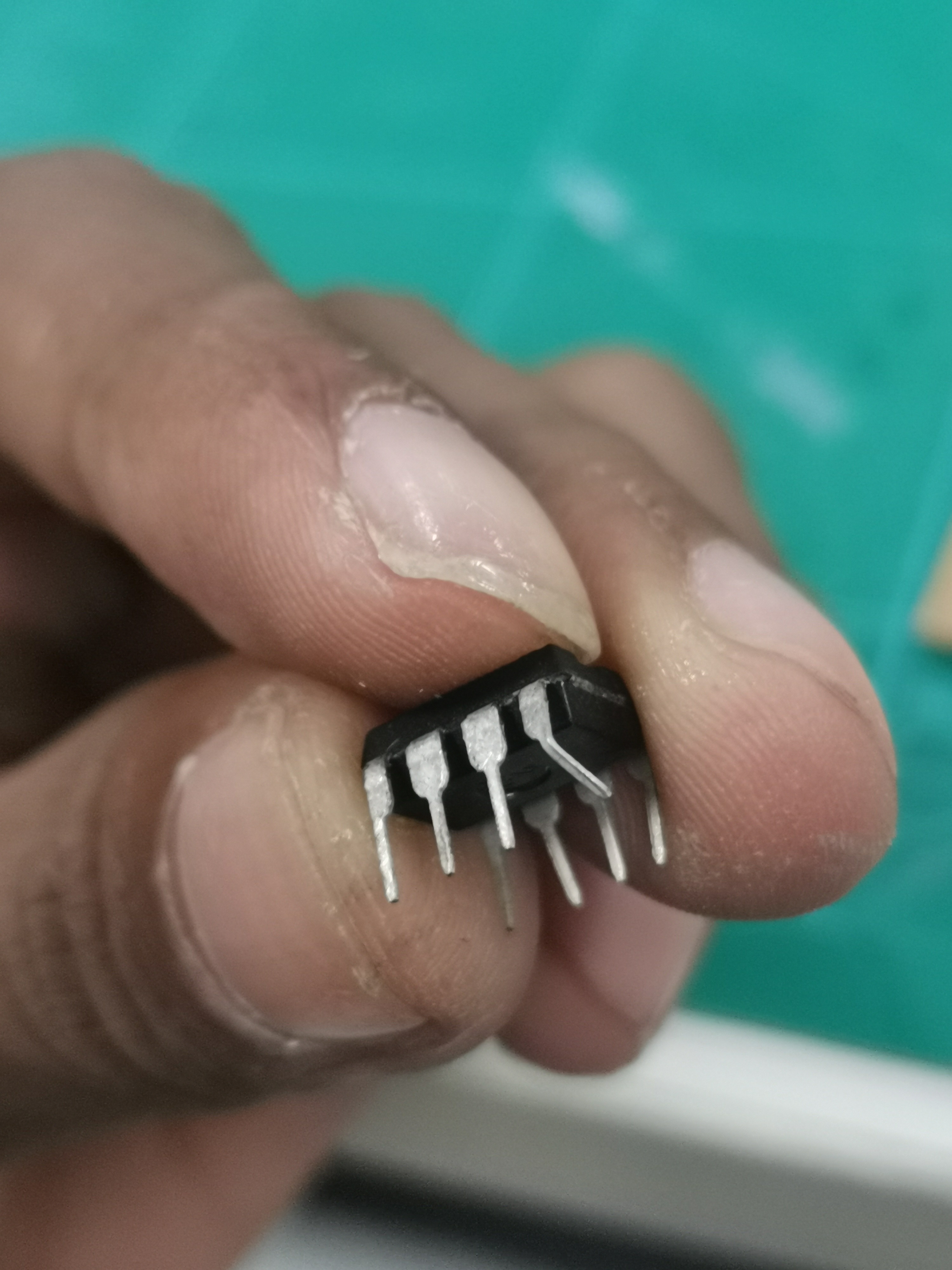

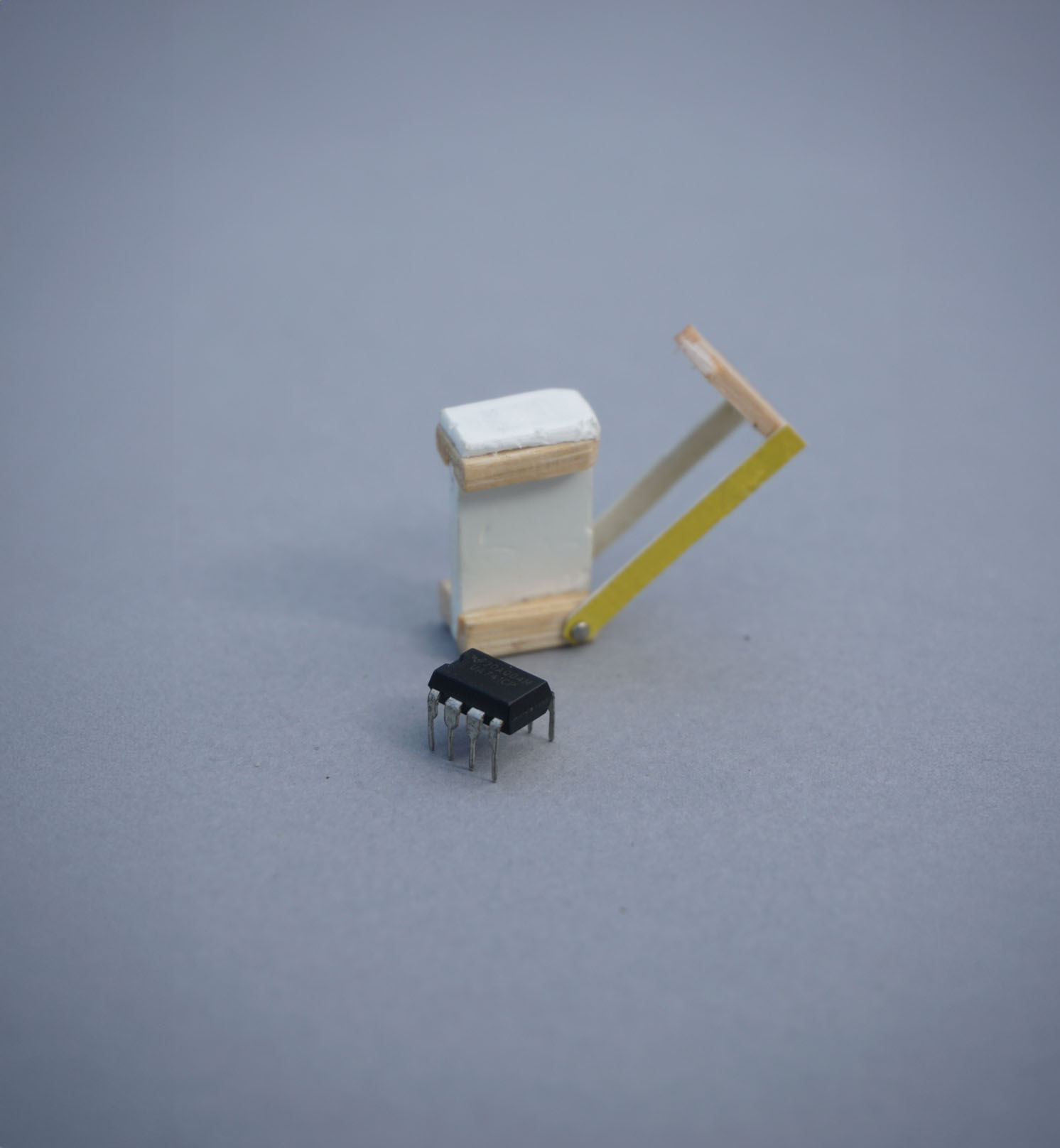

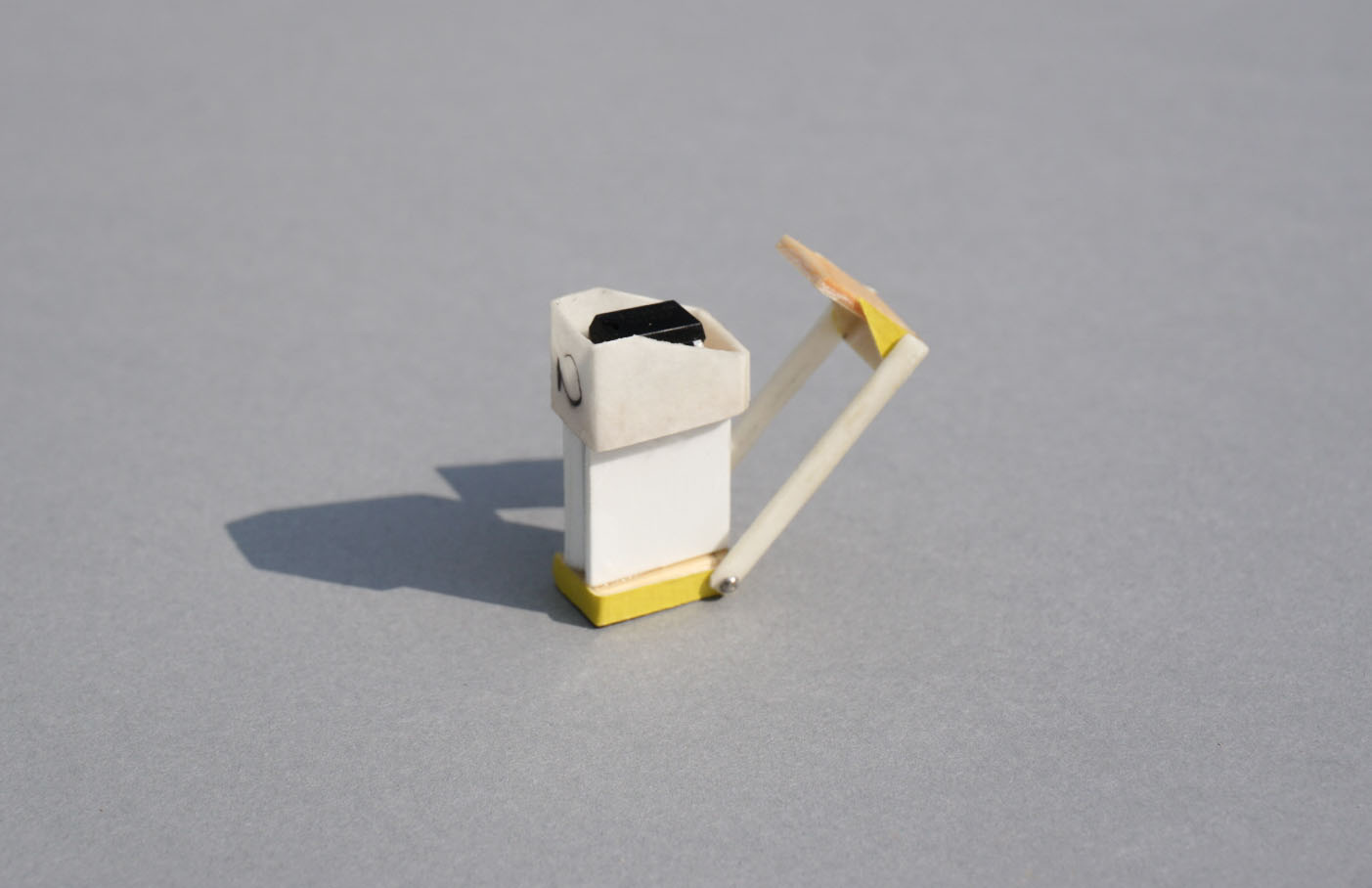

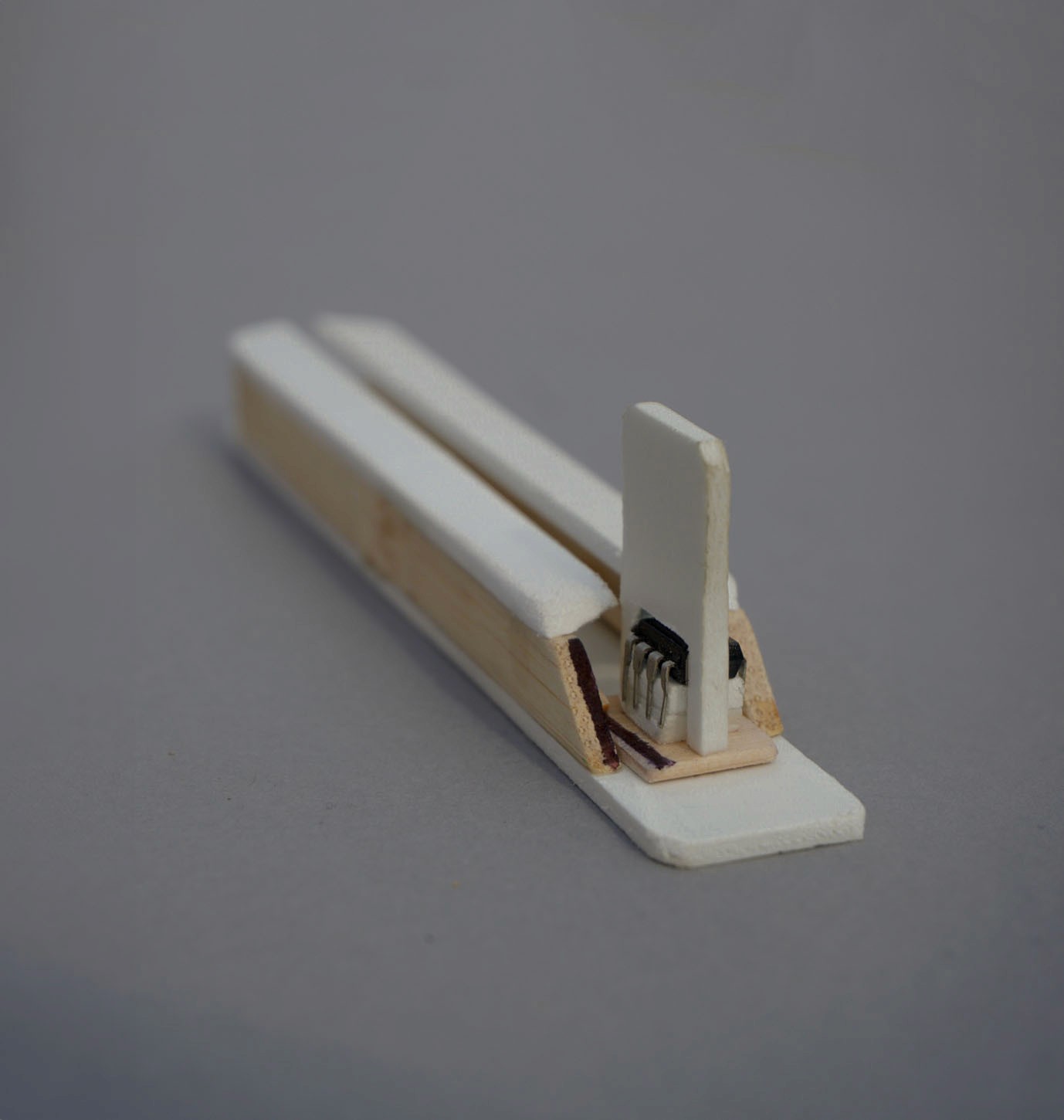

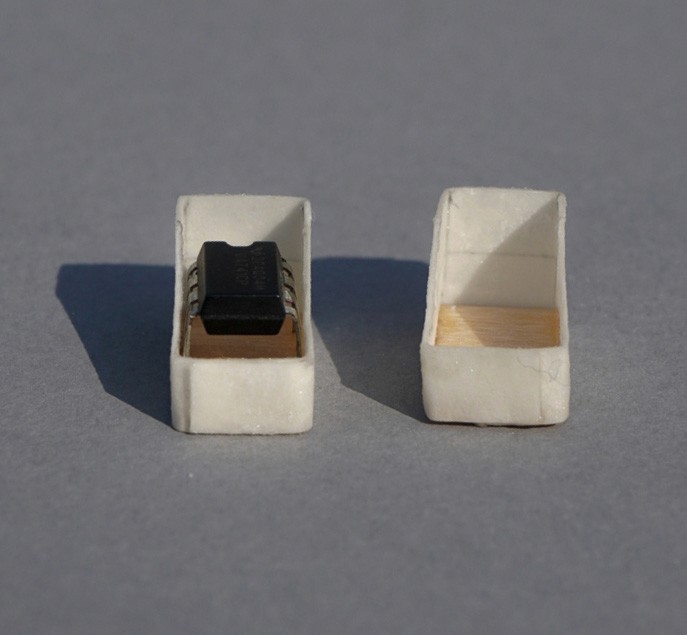

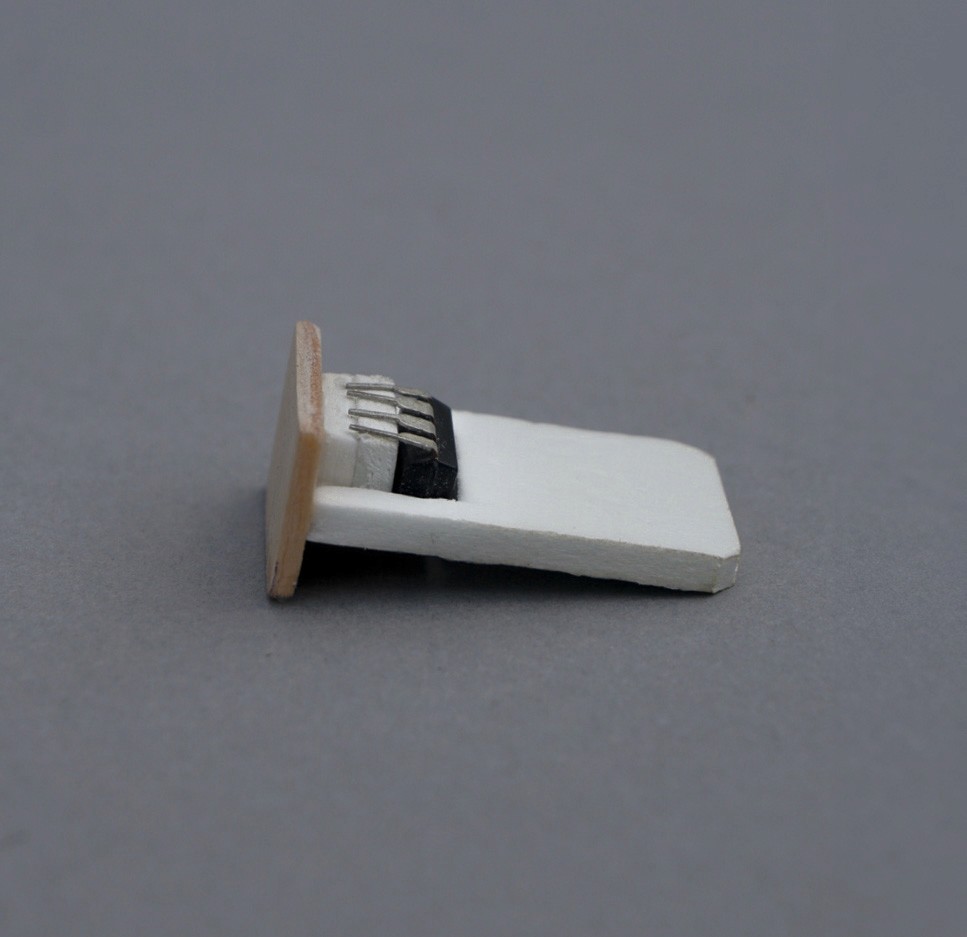

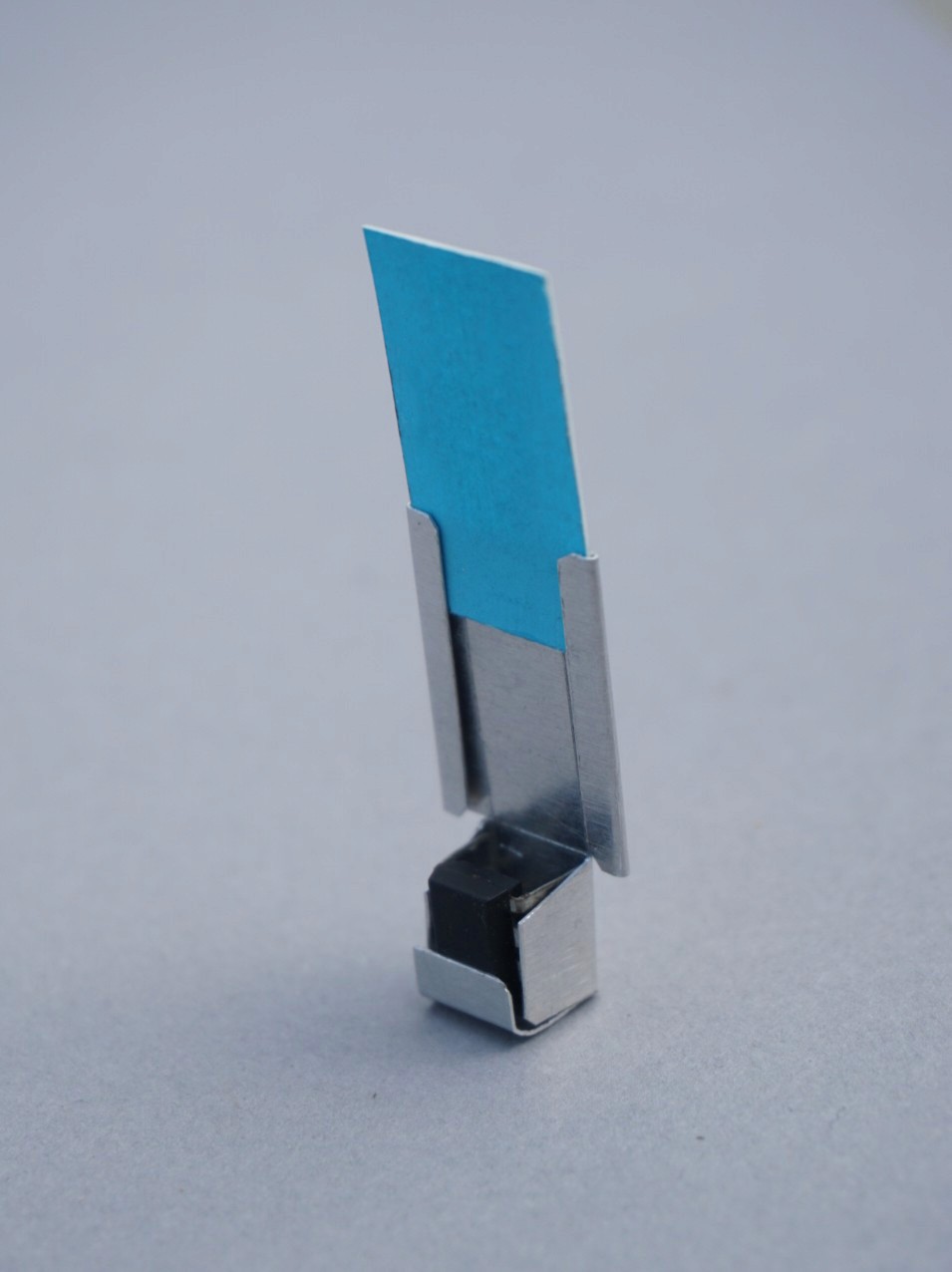

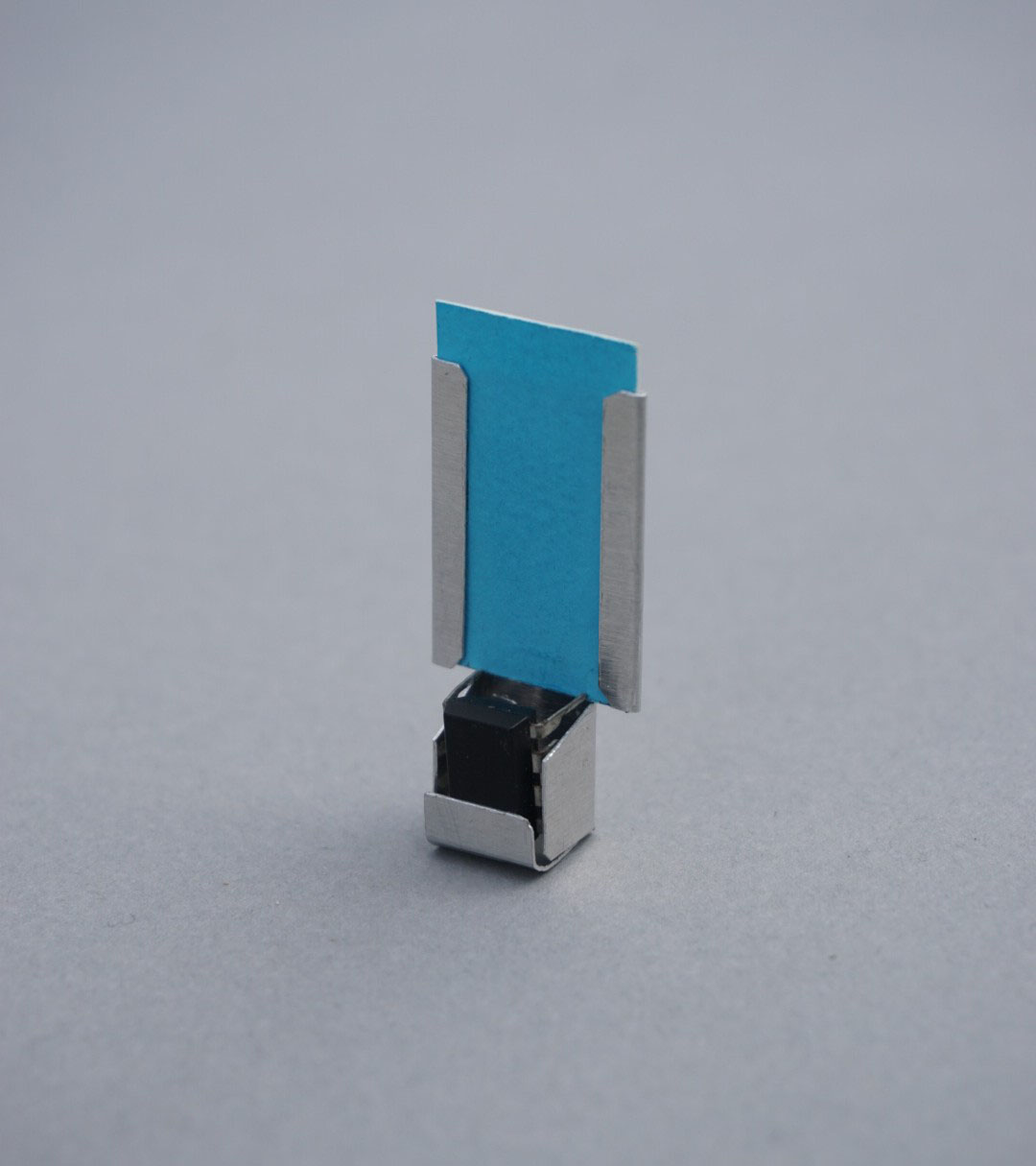

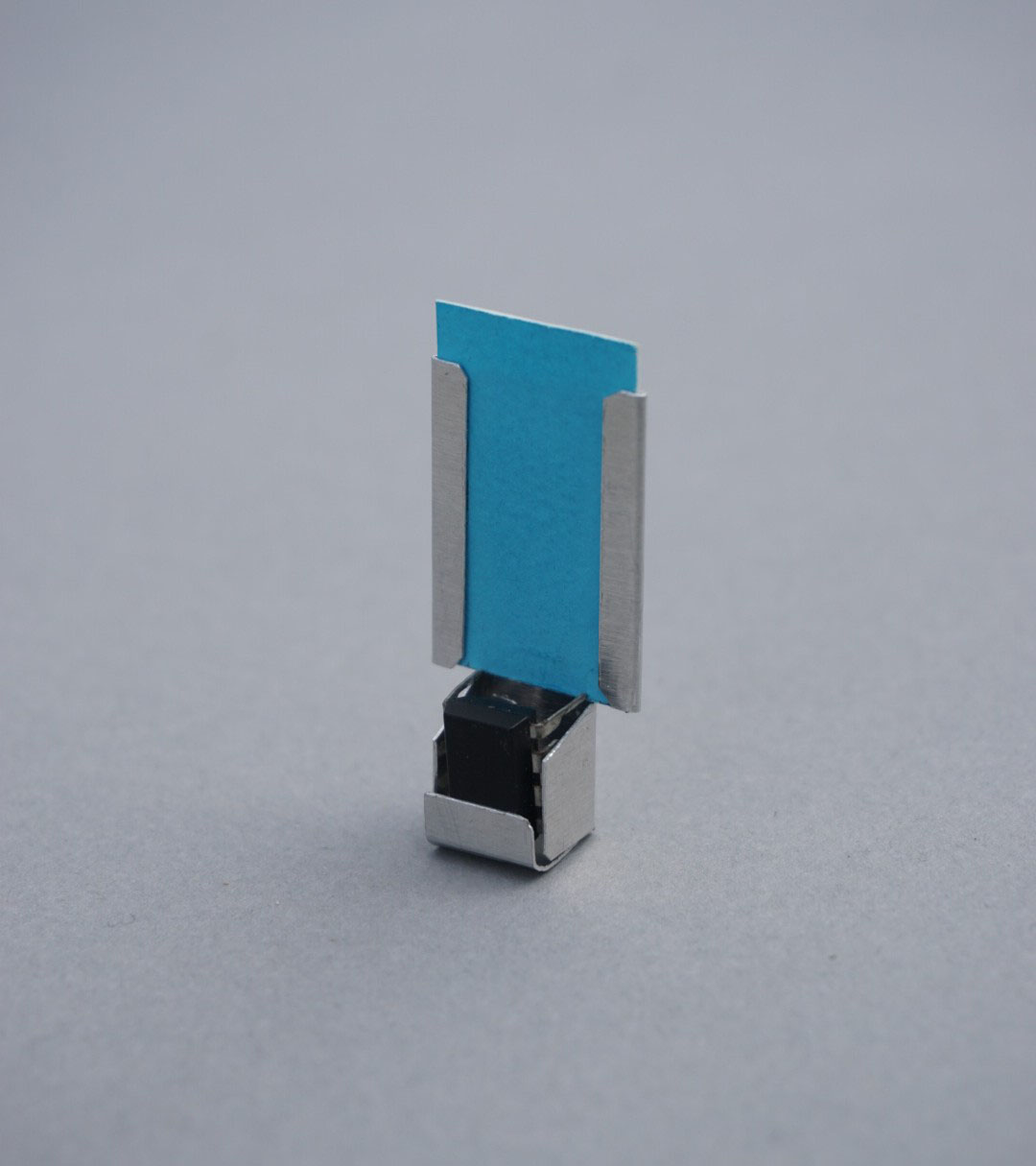

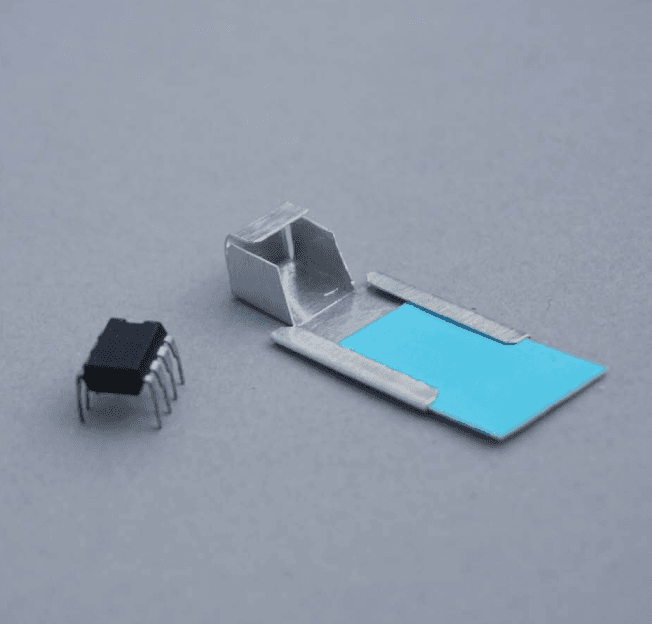

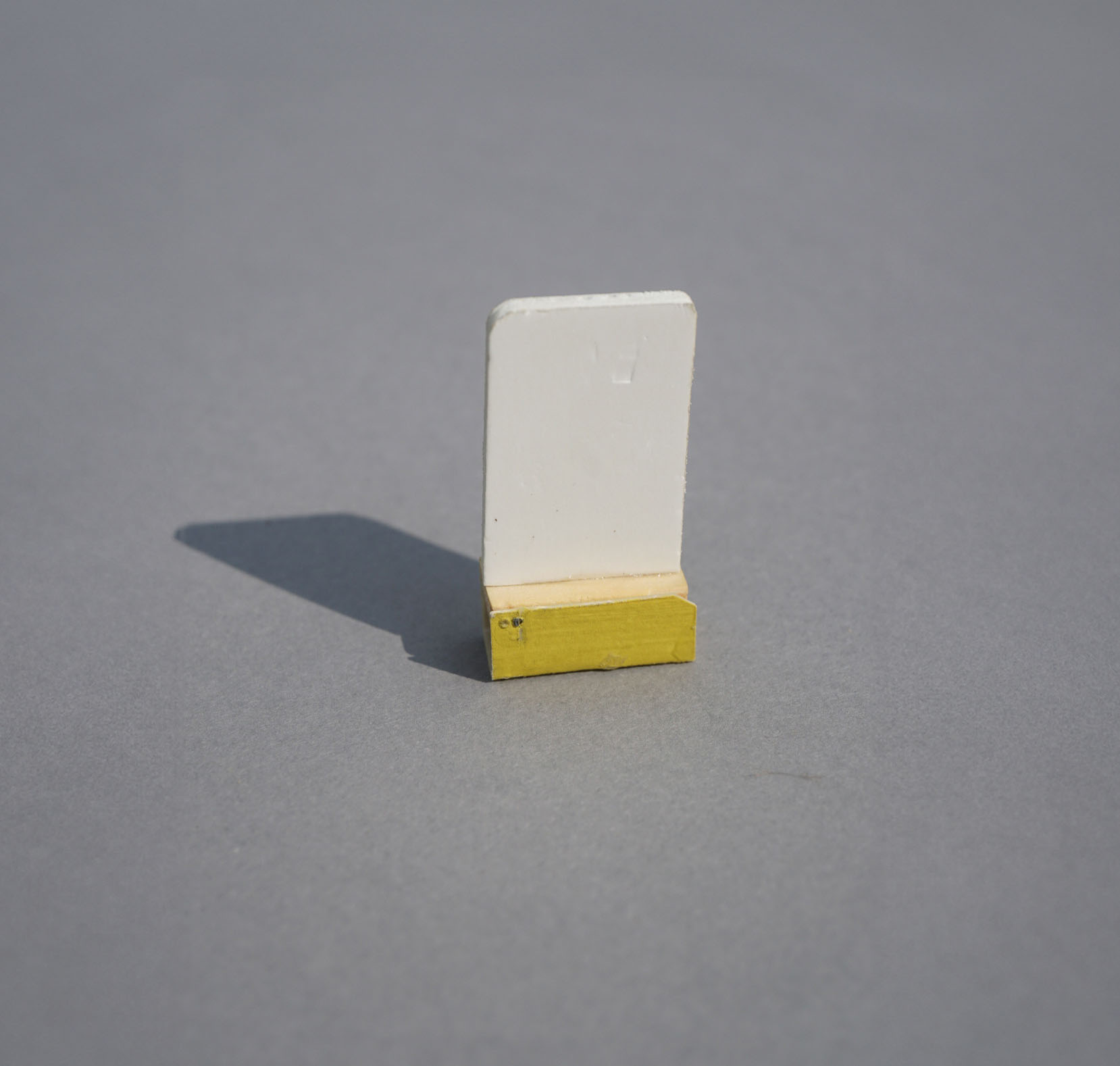

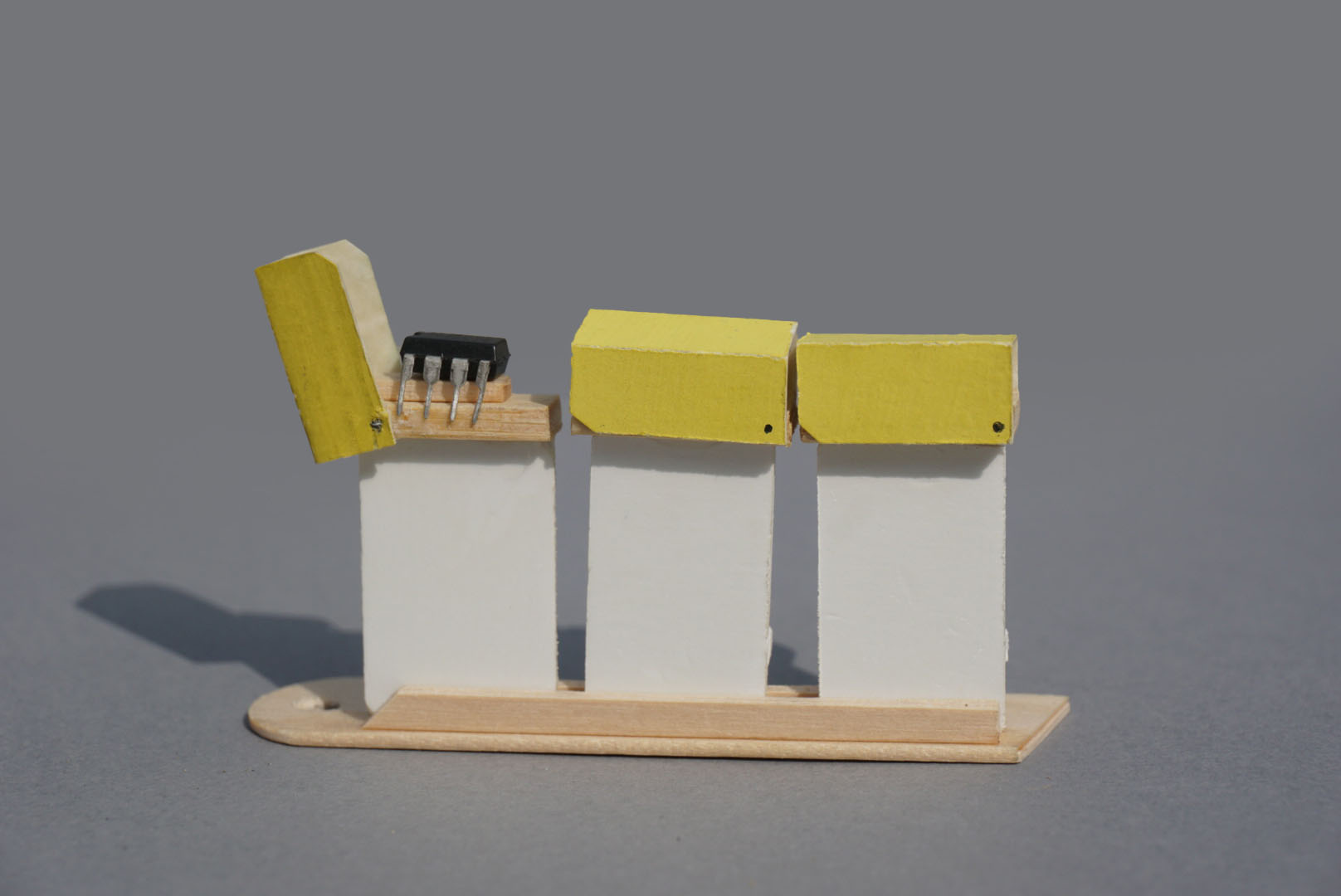

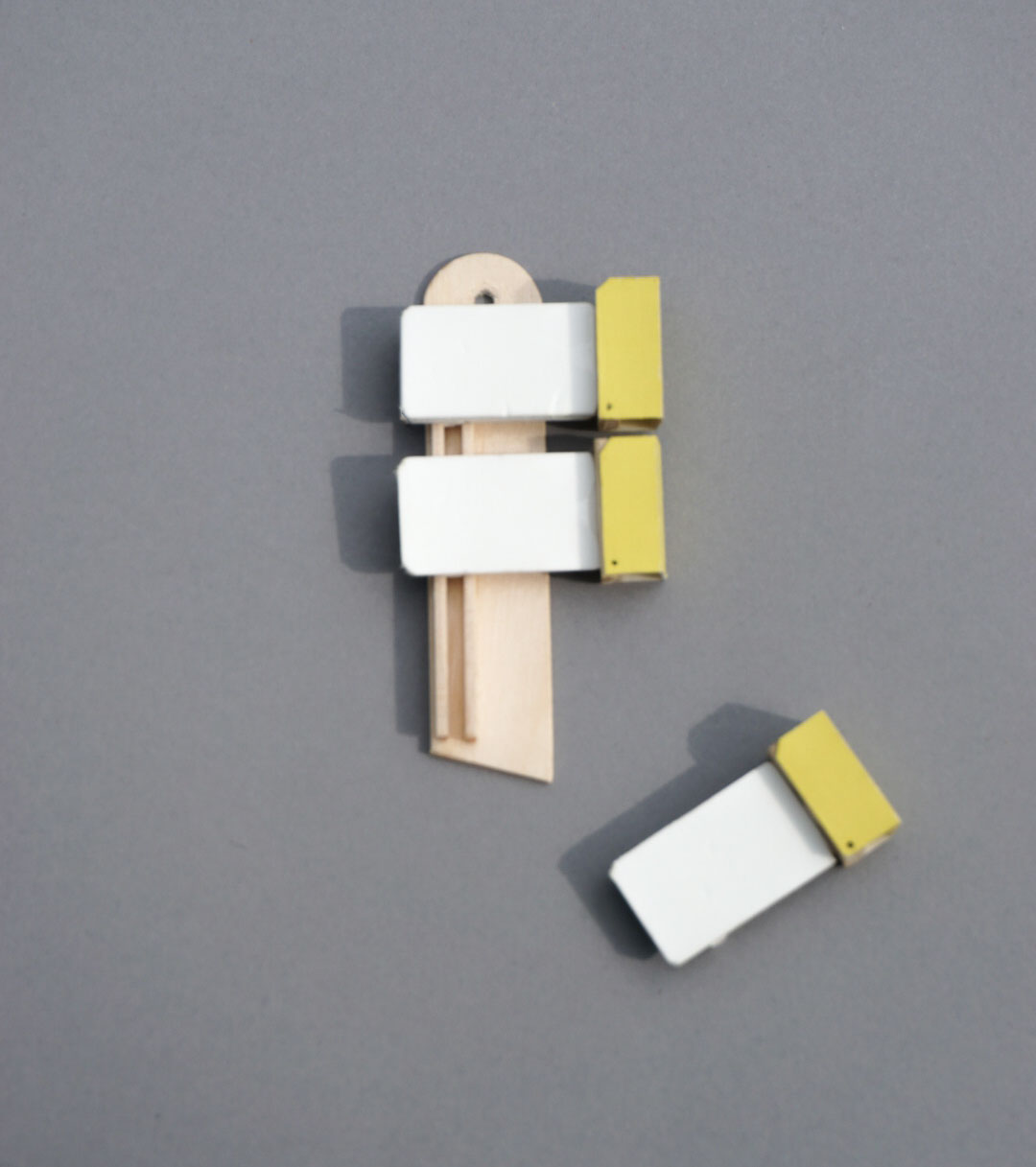

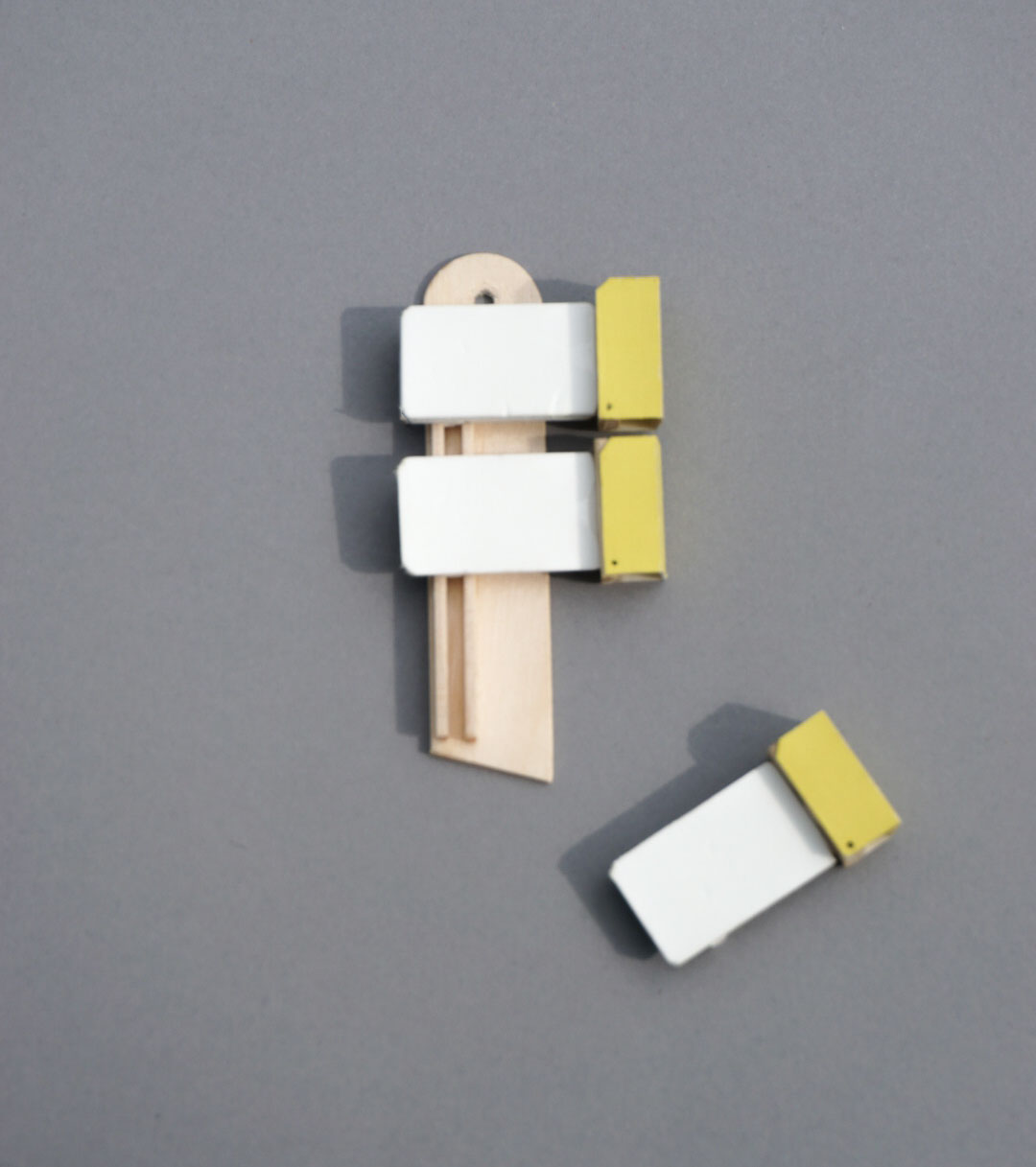

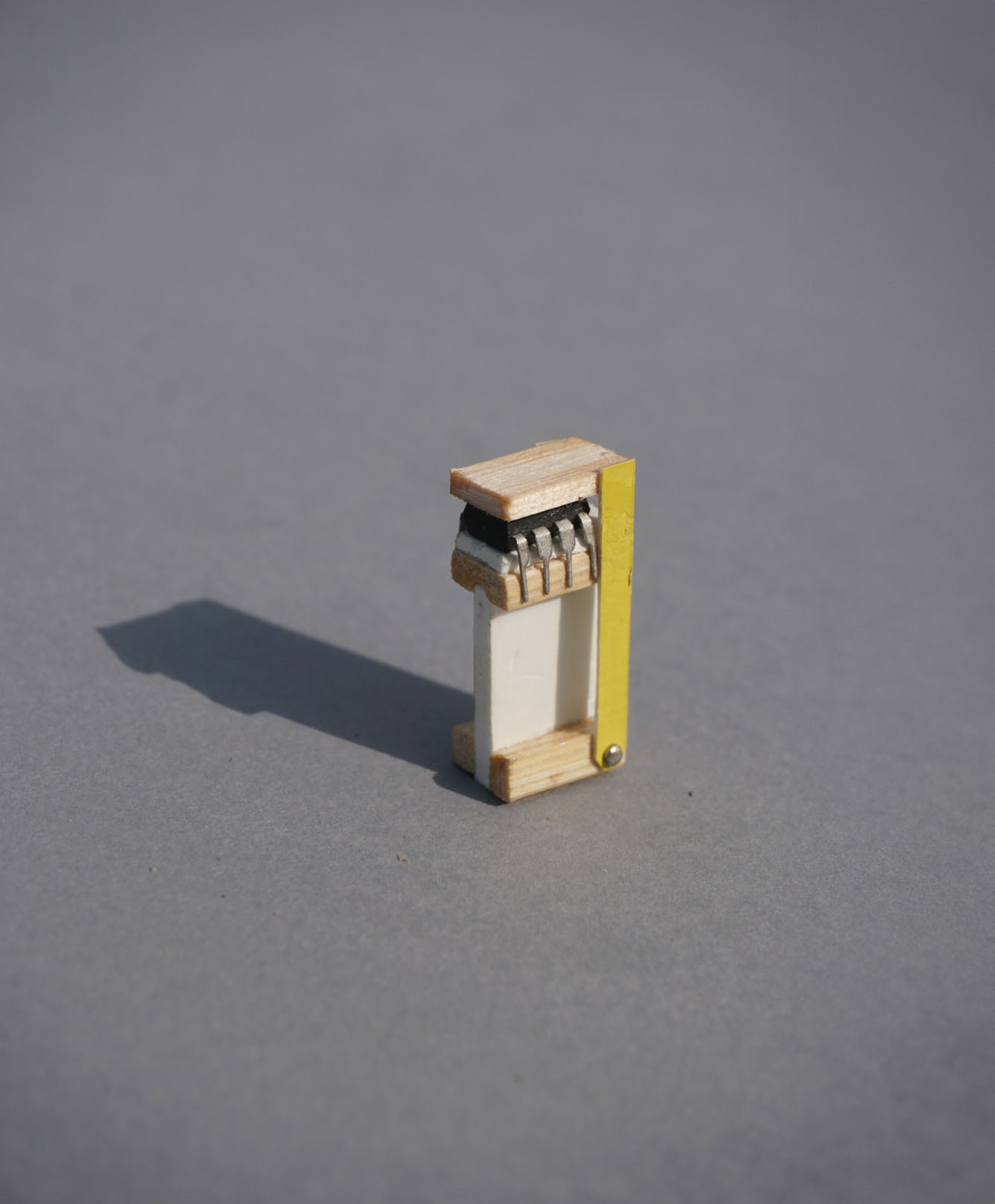

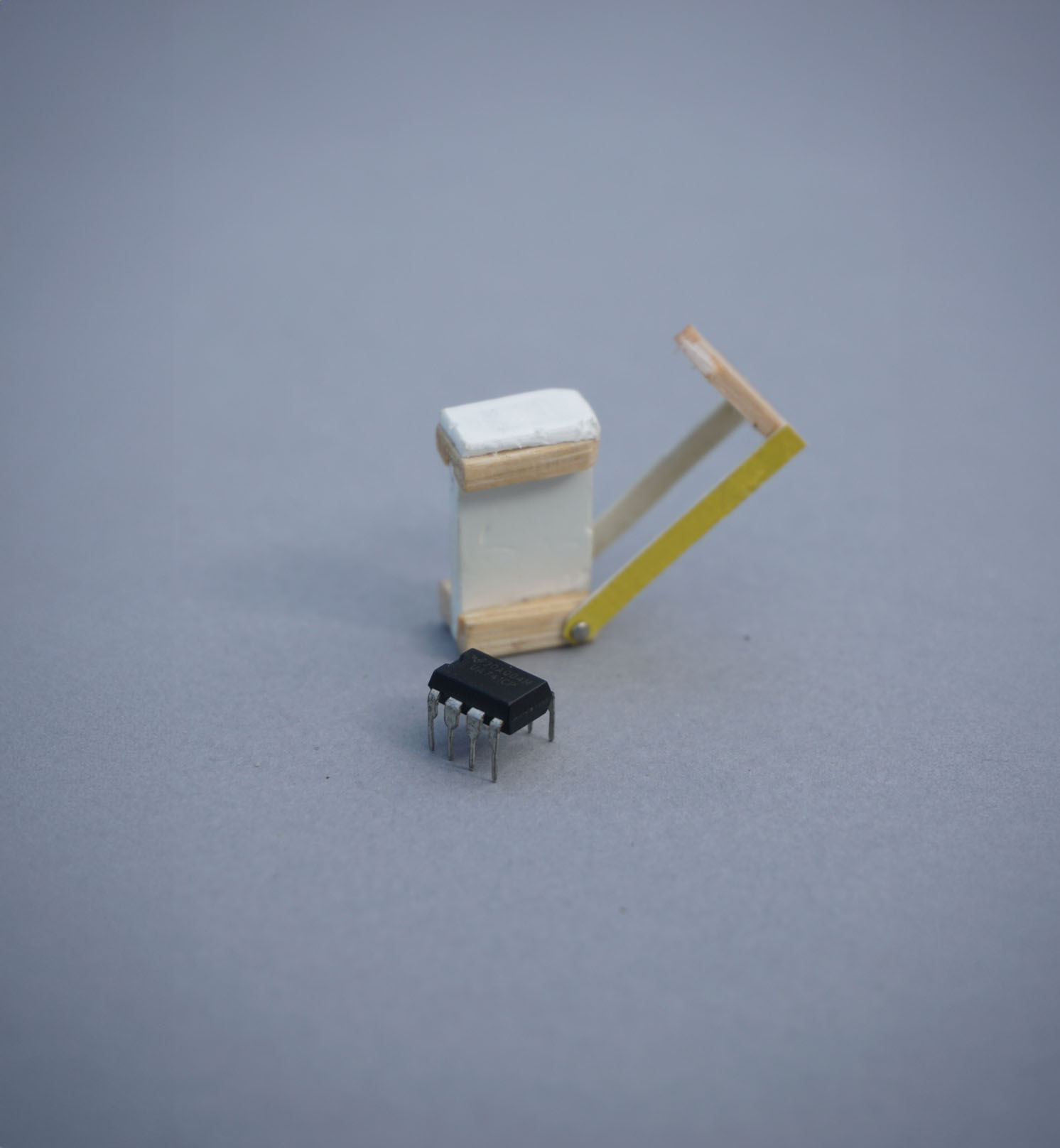

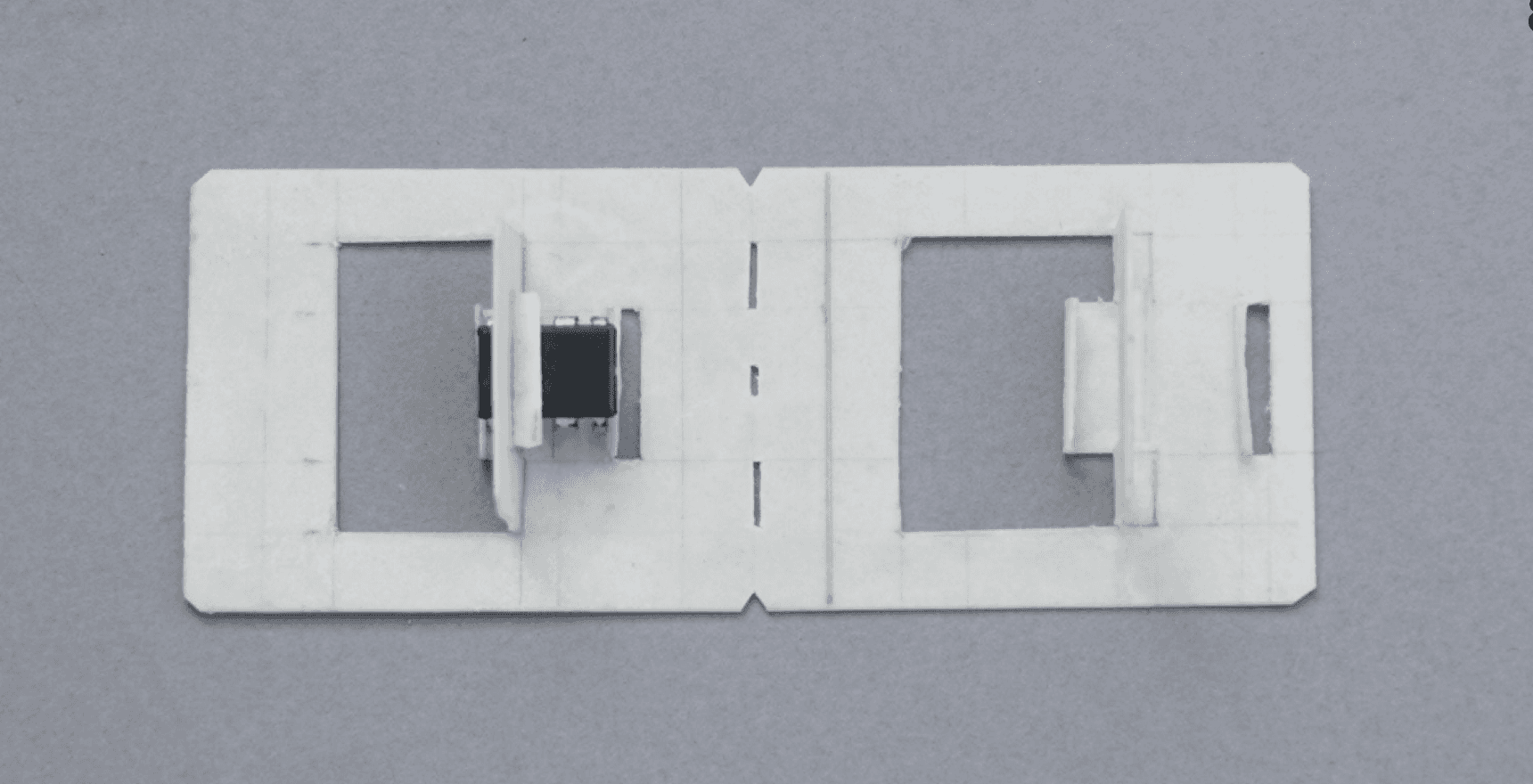

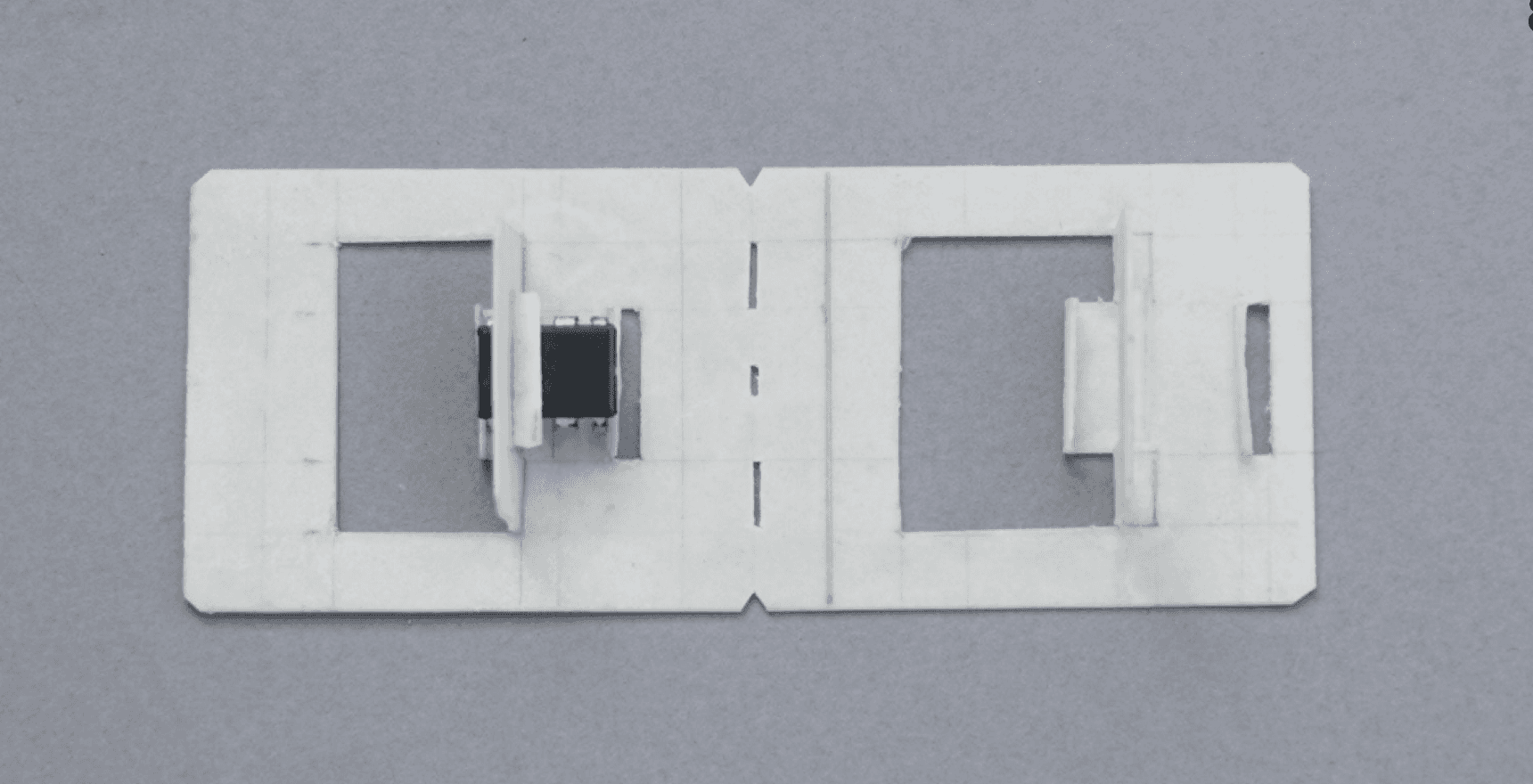

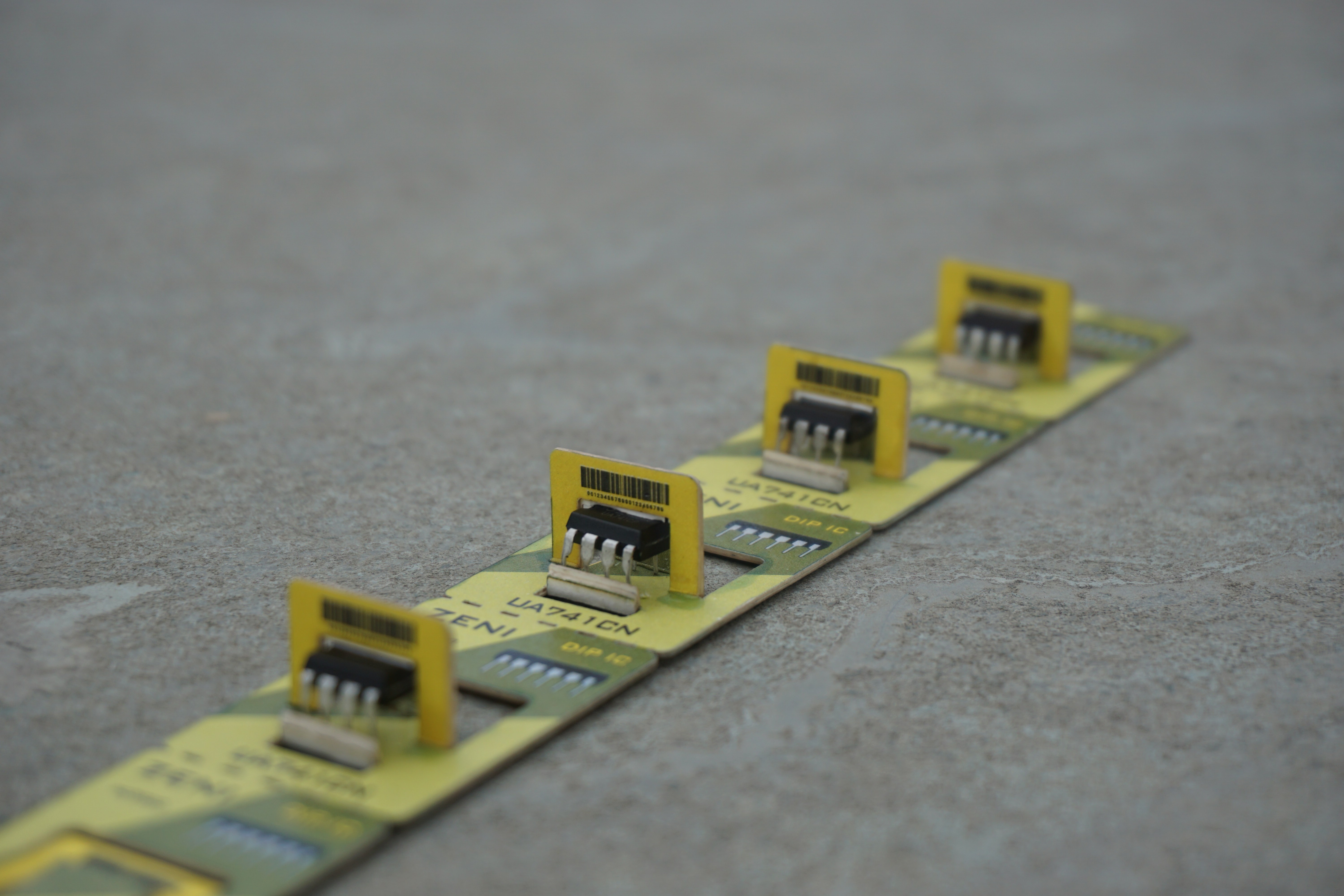

REJECTED

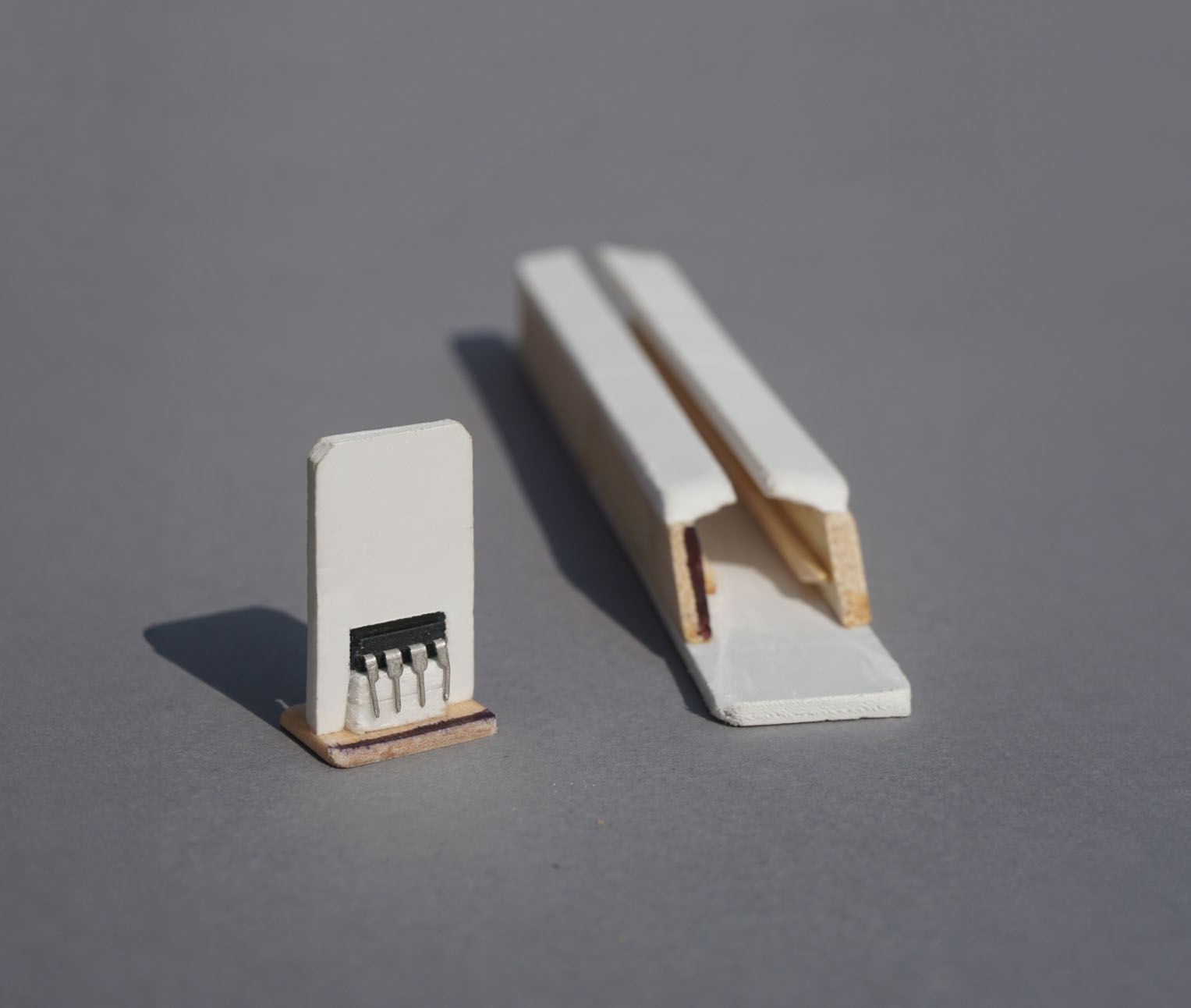

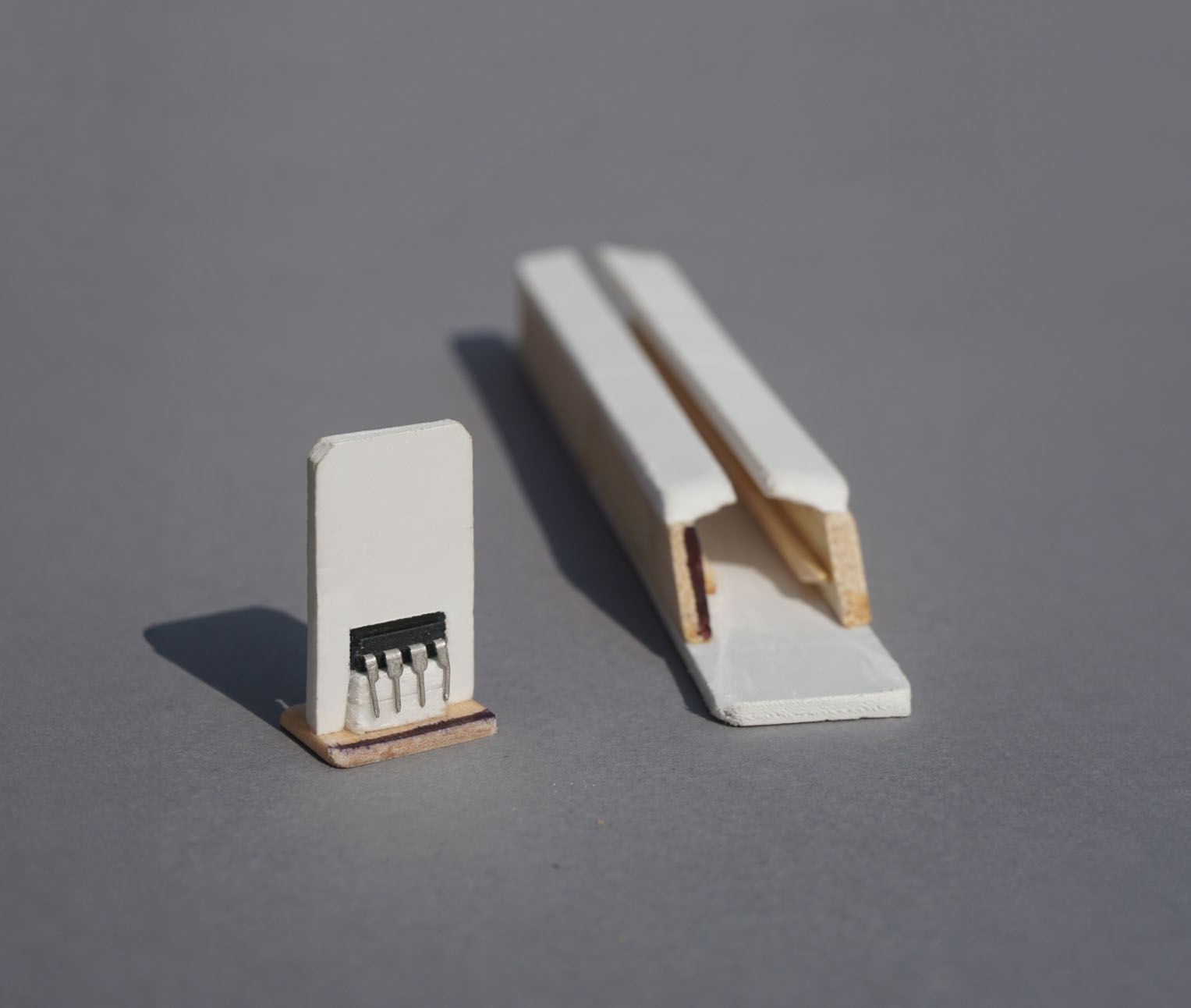

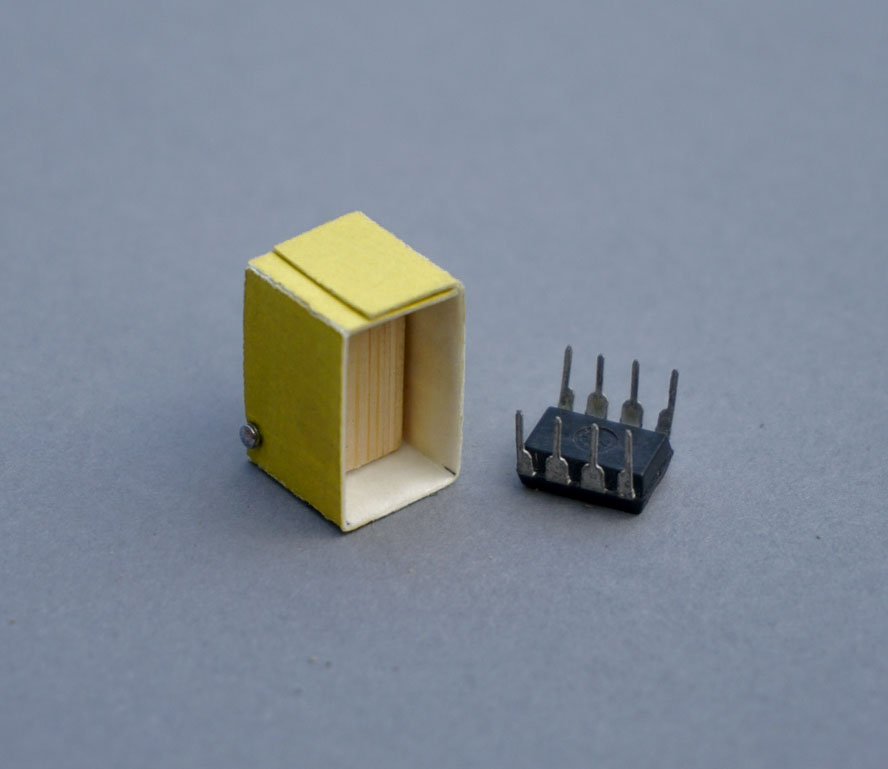

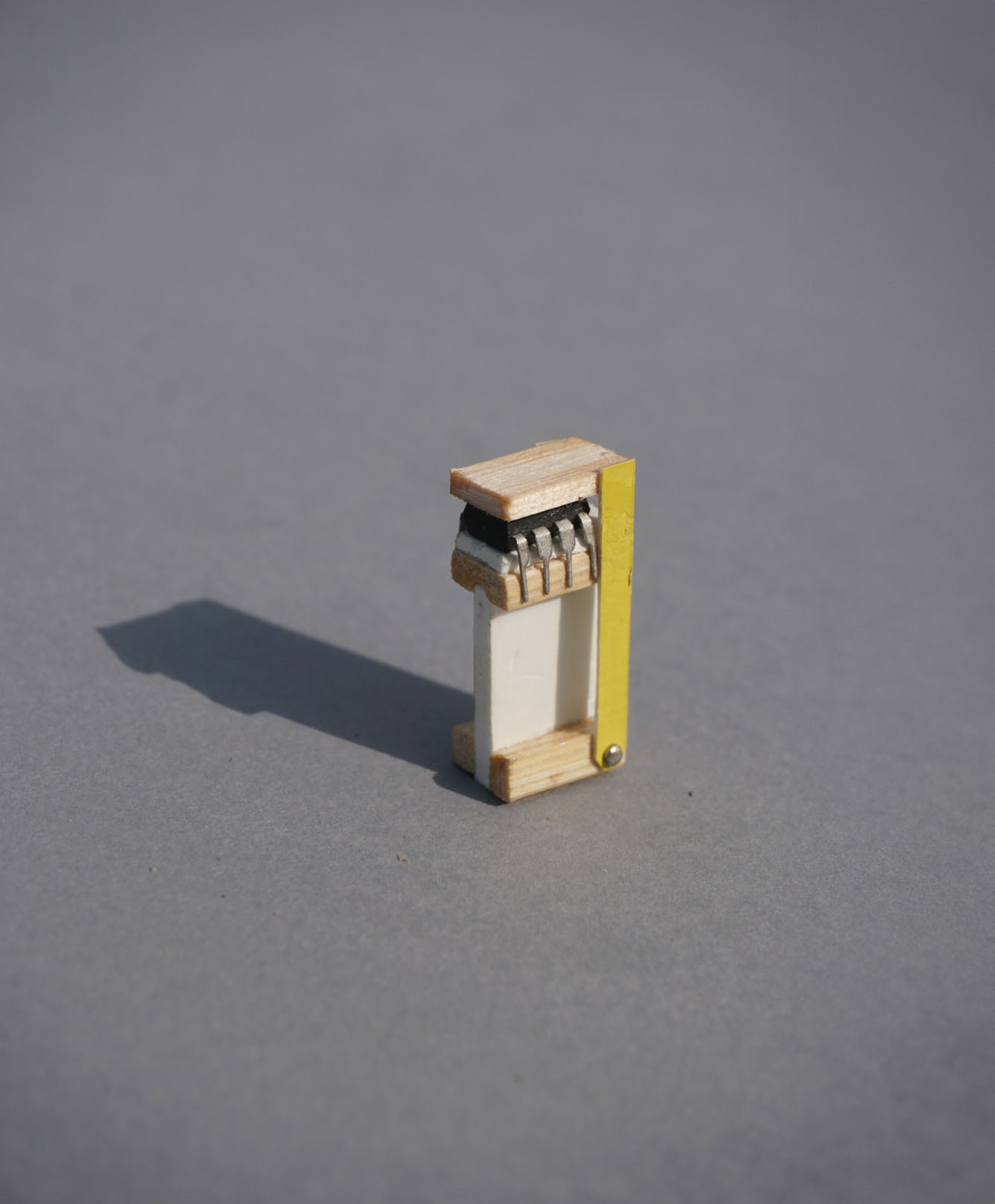

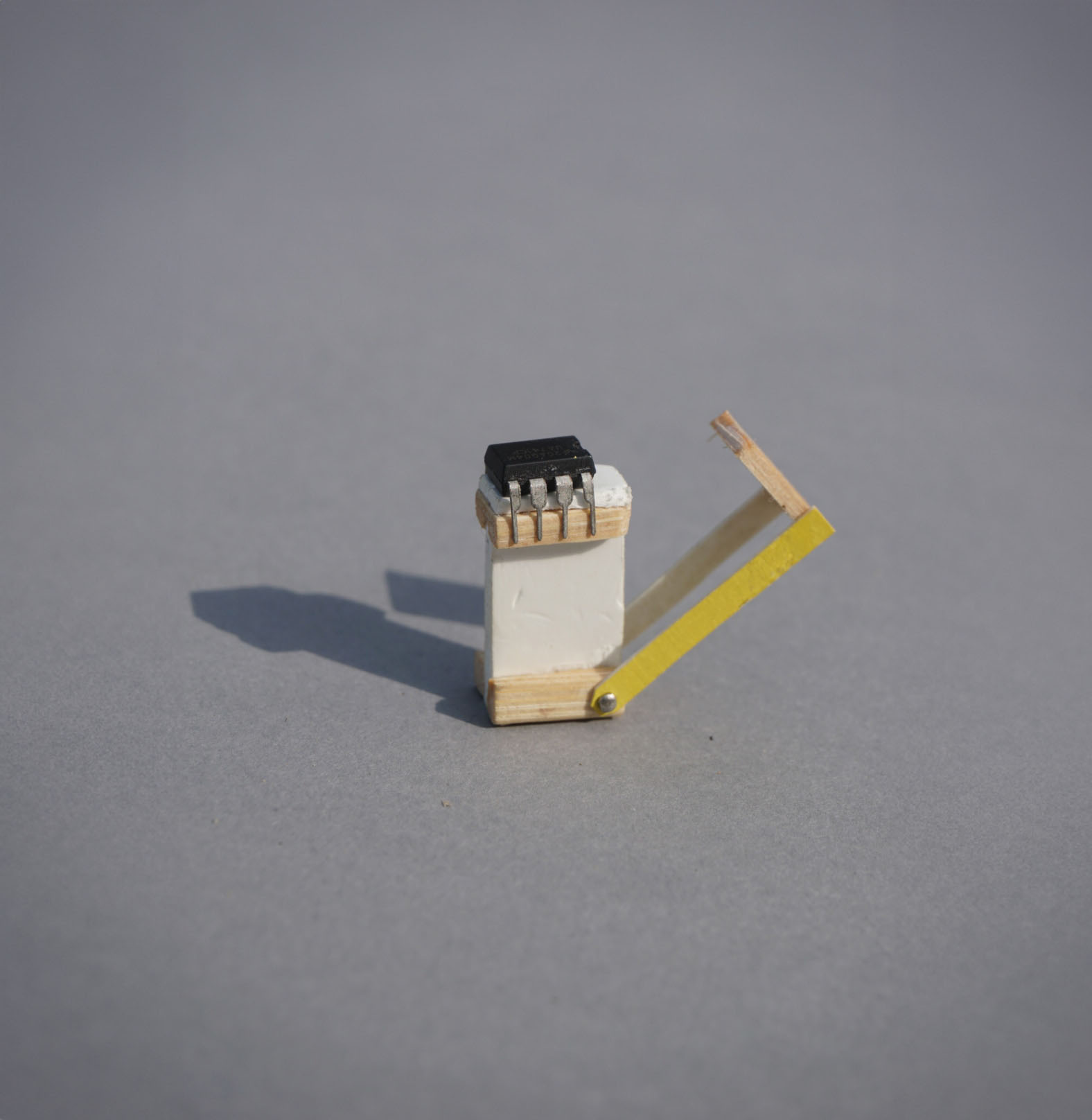

This prototype was second on the list,

but rejected for its tiny parts and

small complexities, thereby making it

less mass manufacturable.

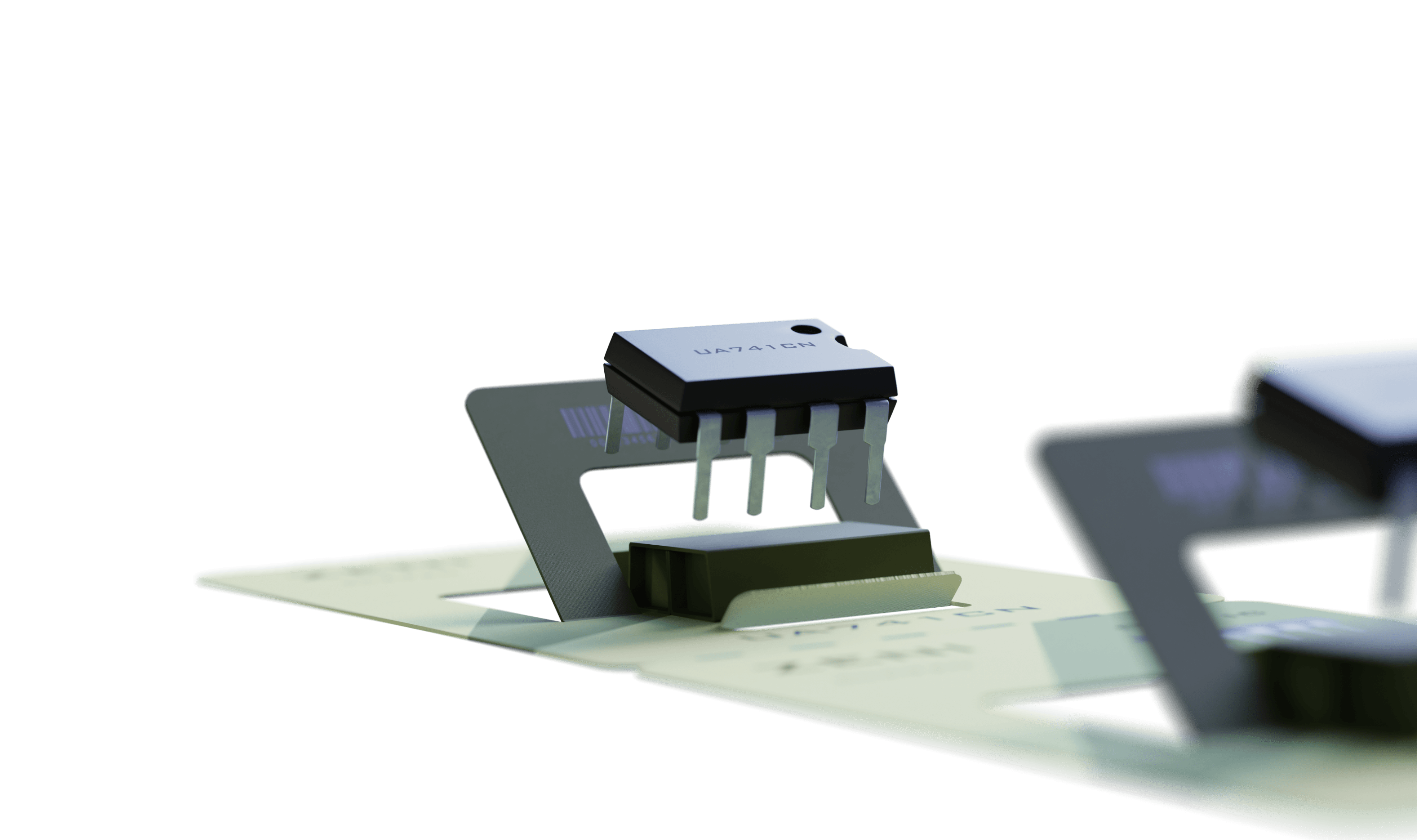

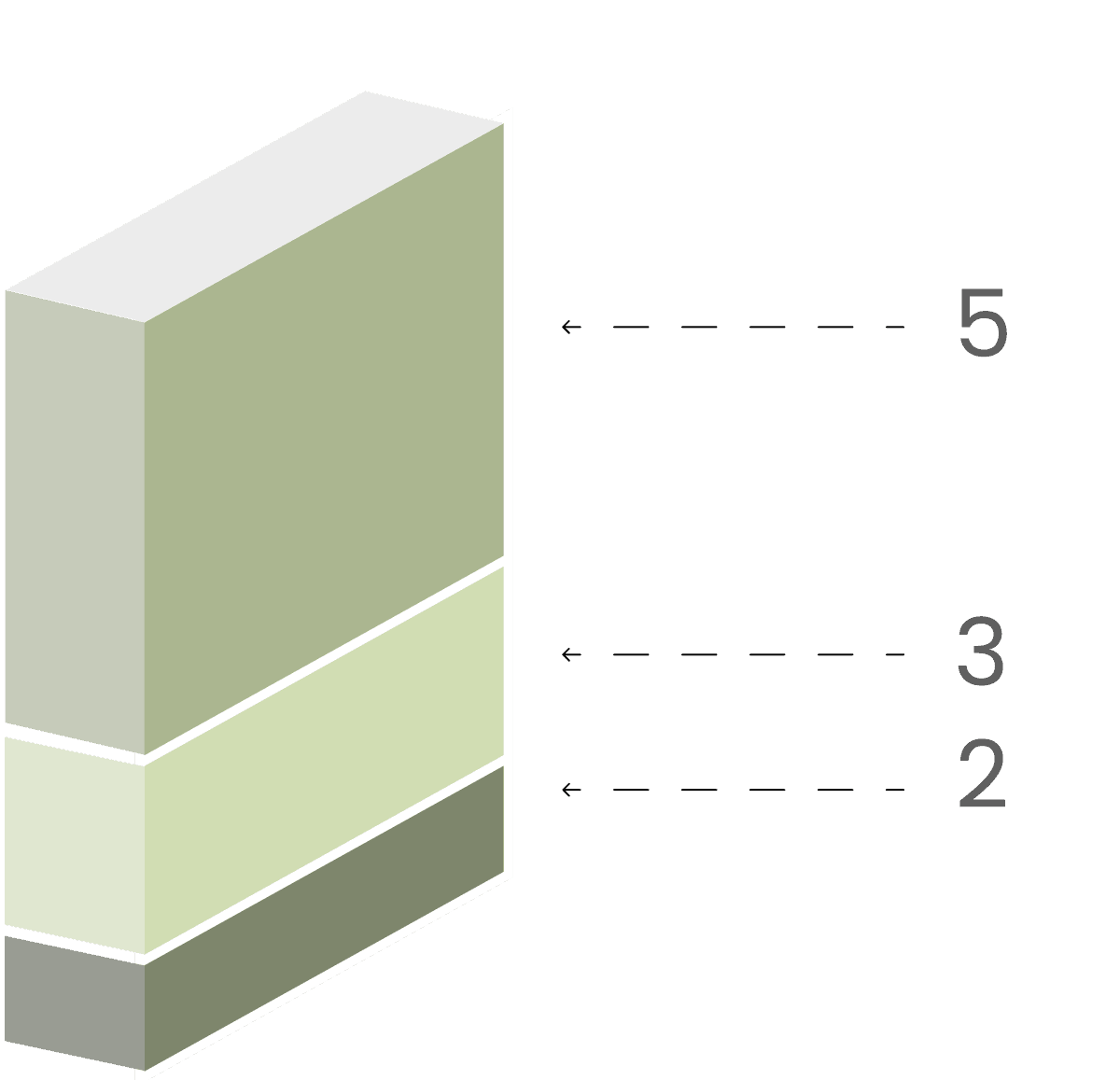

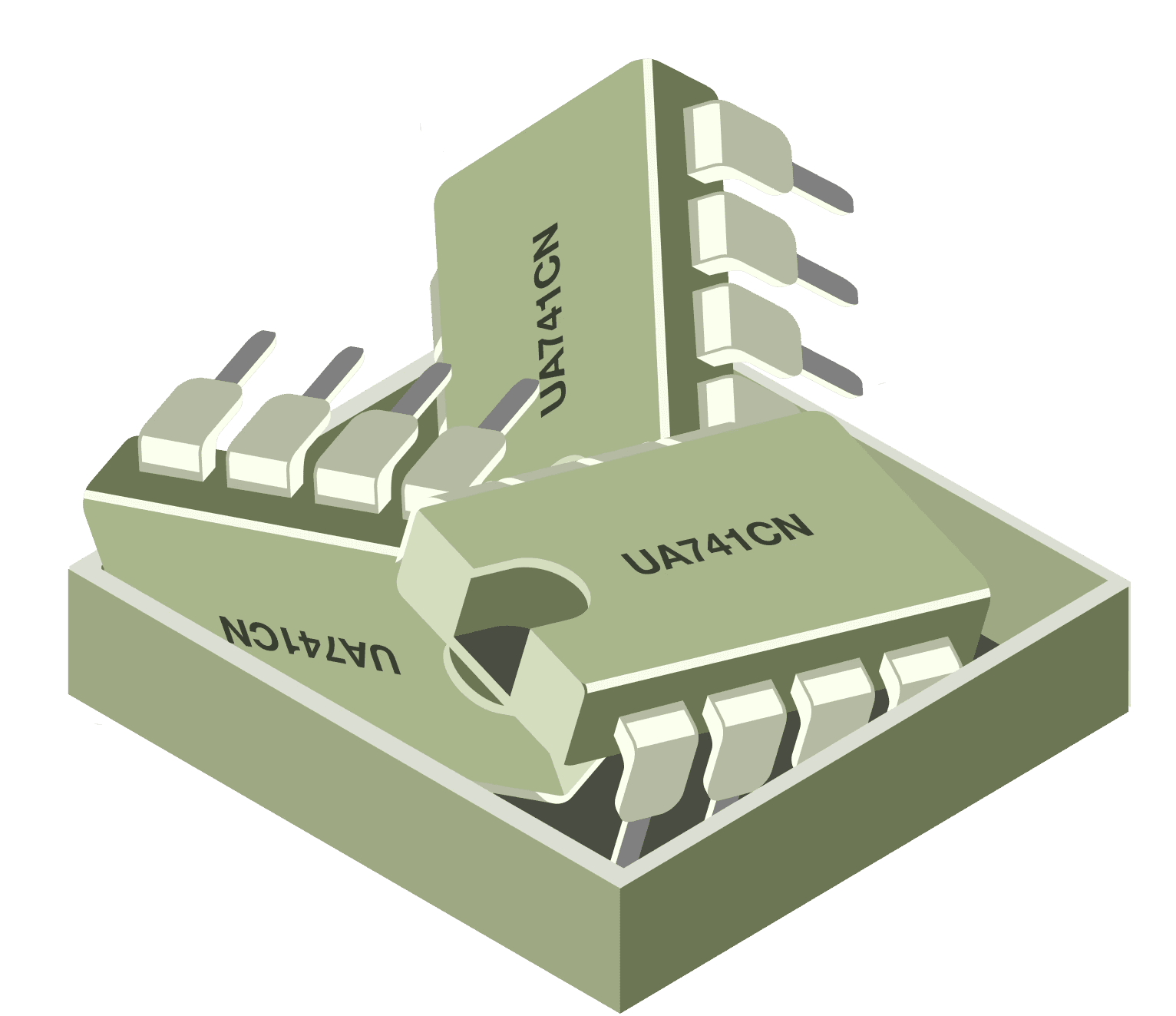

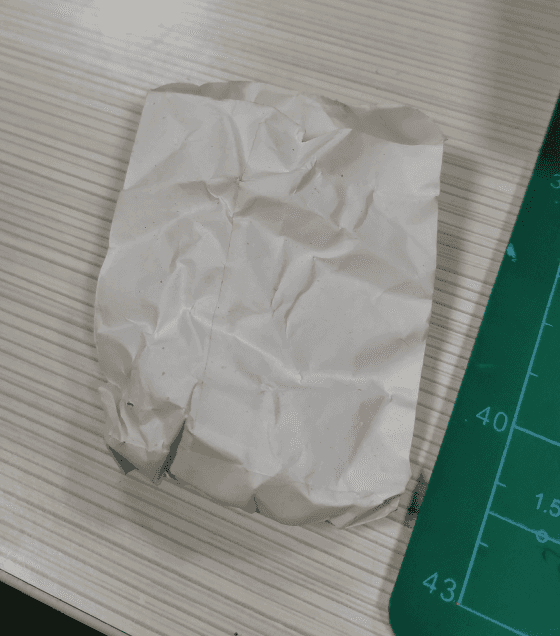

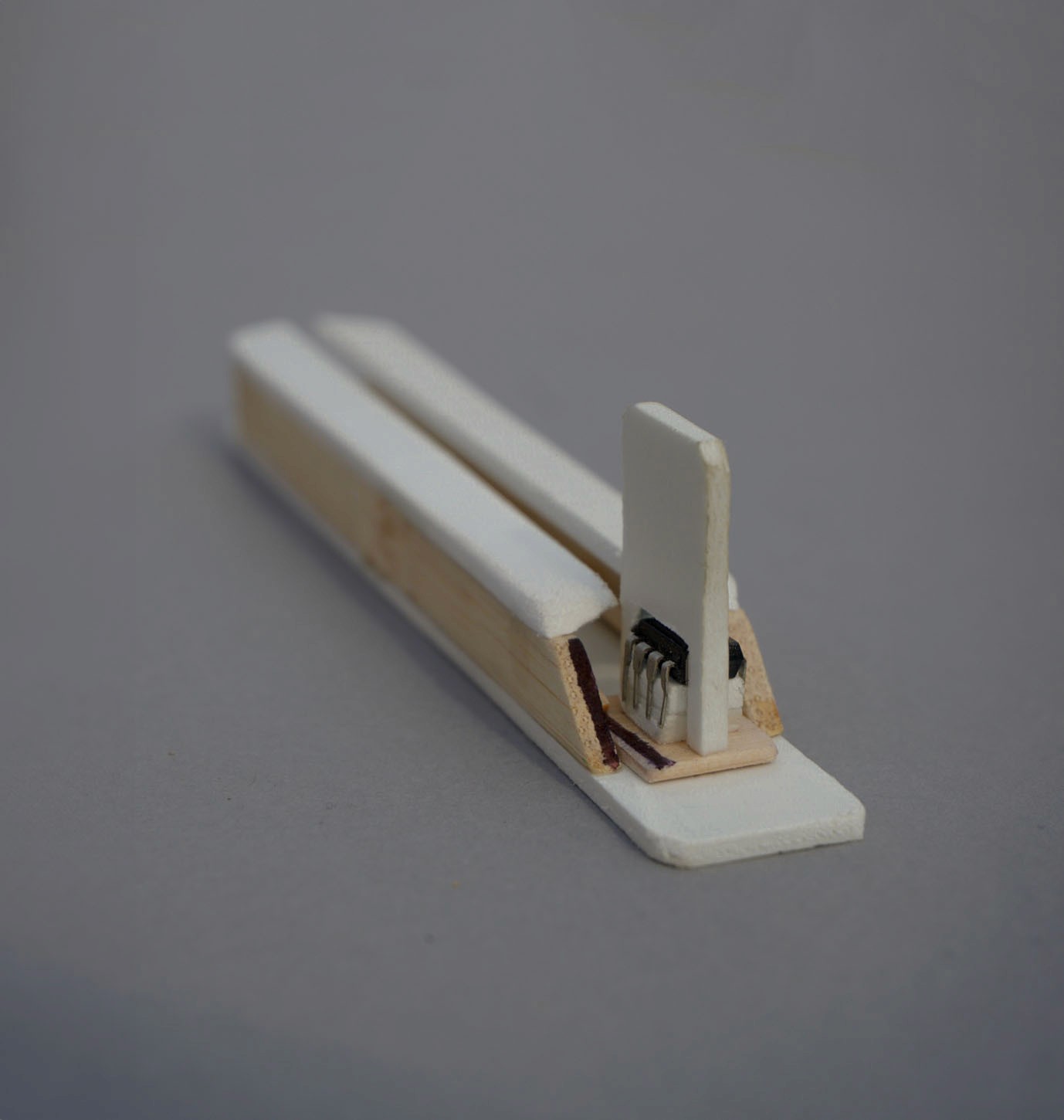

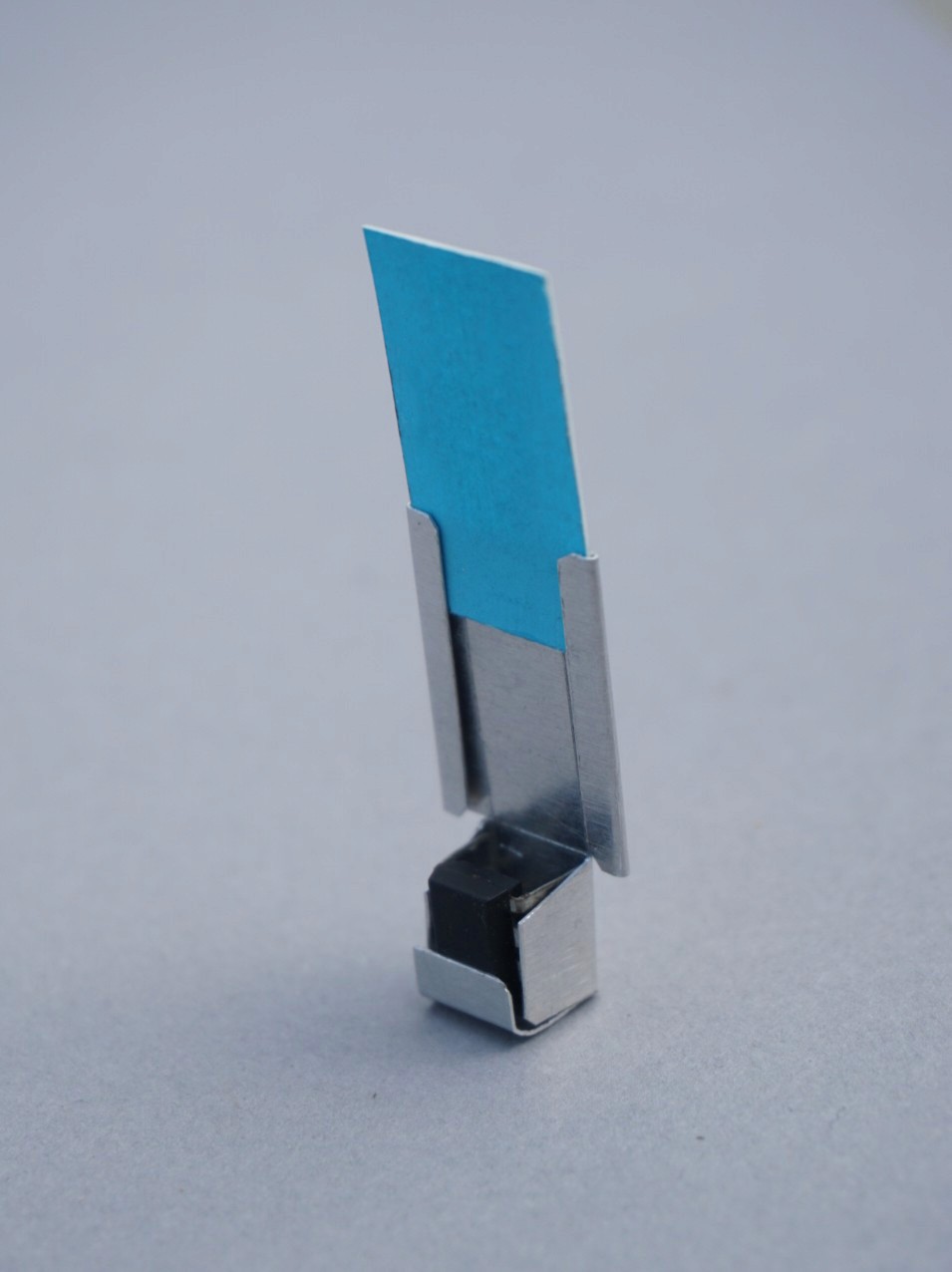

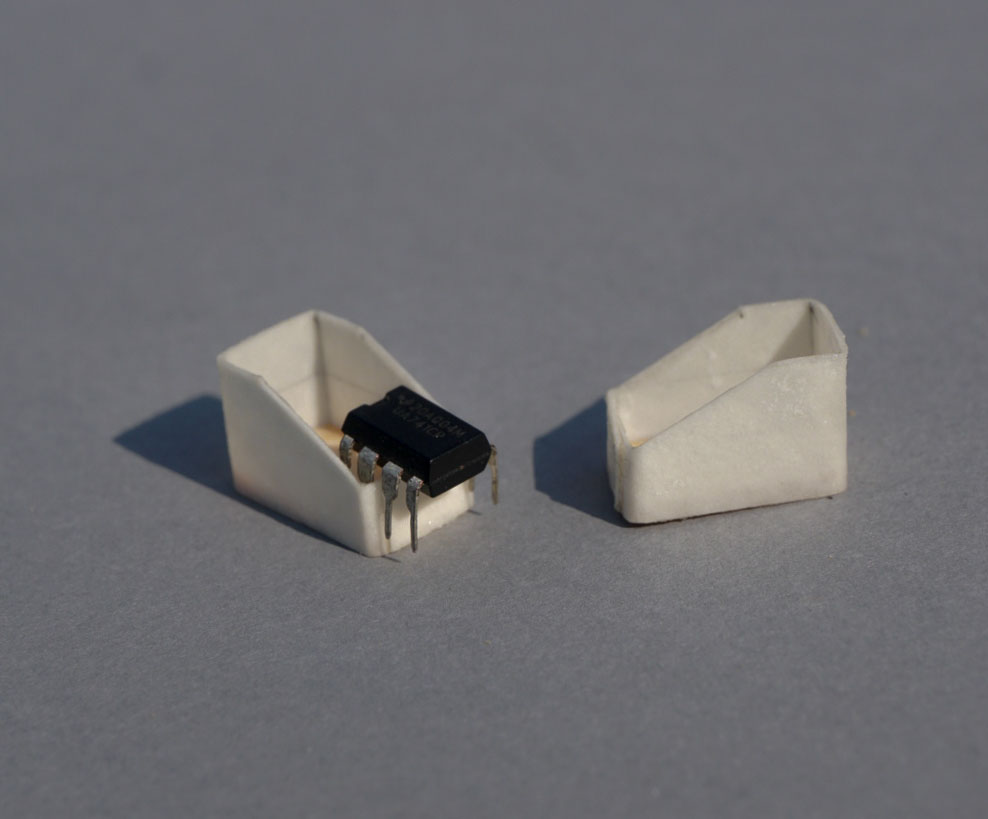

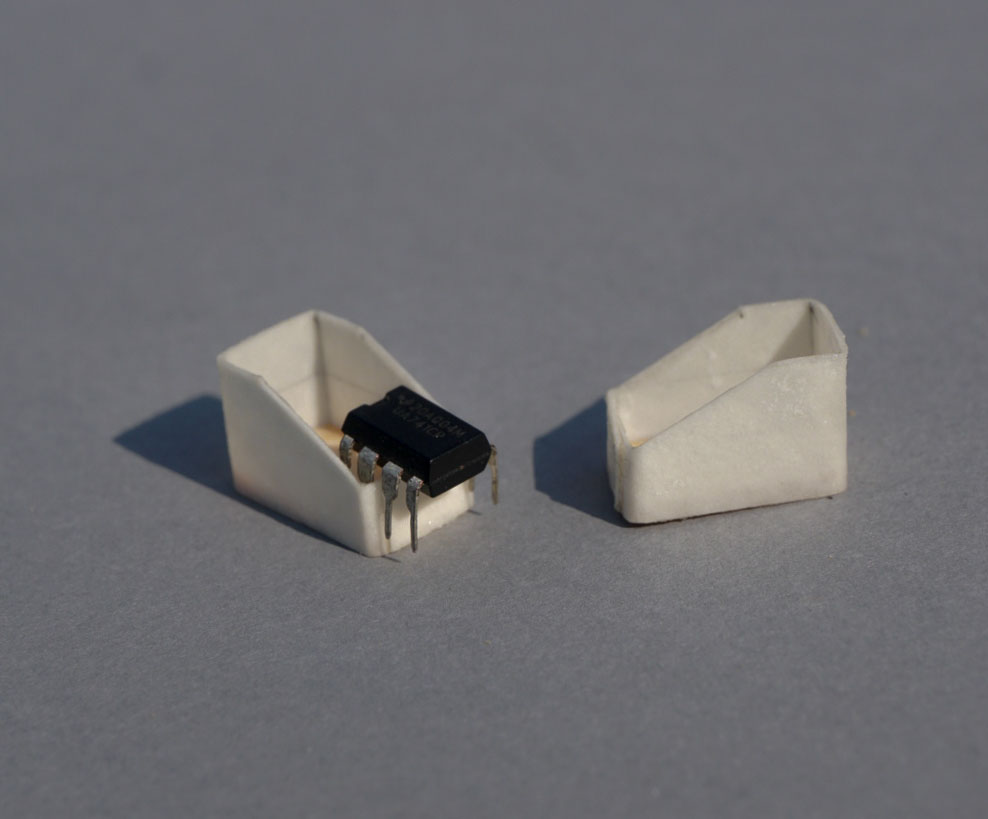

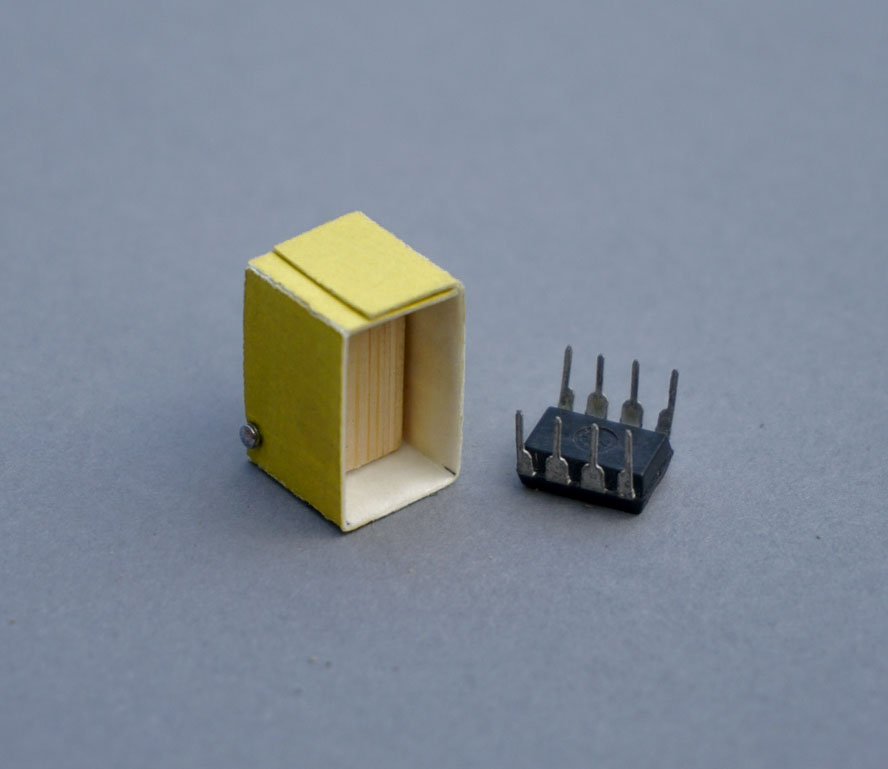

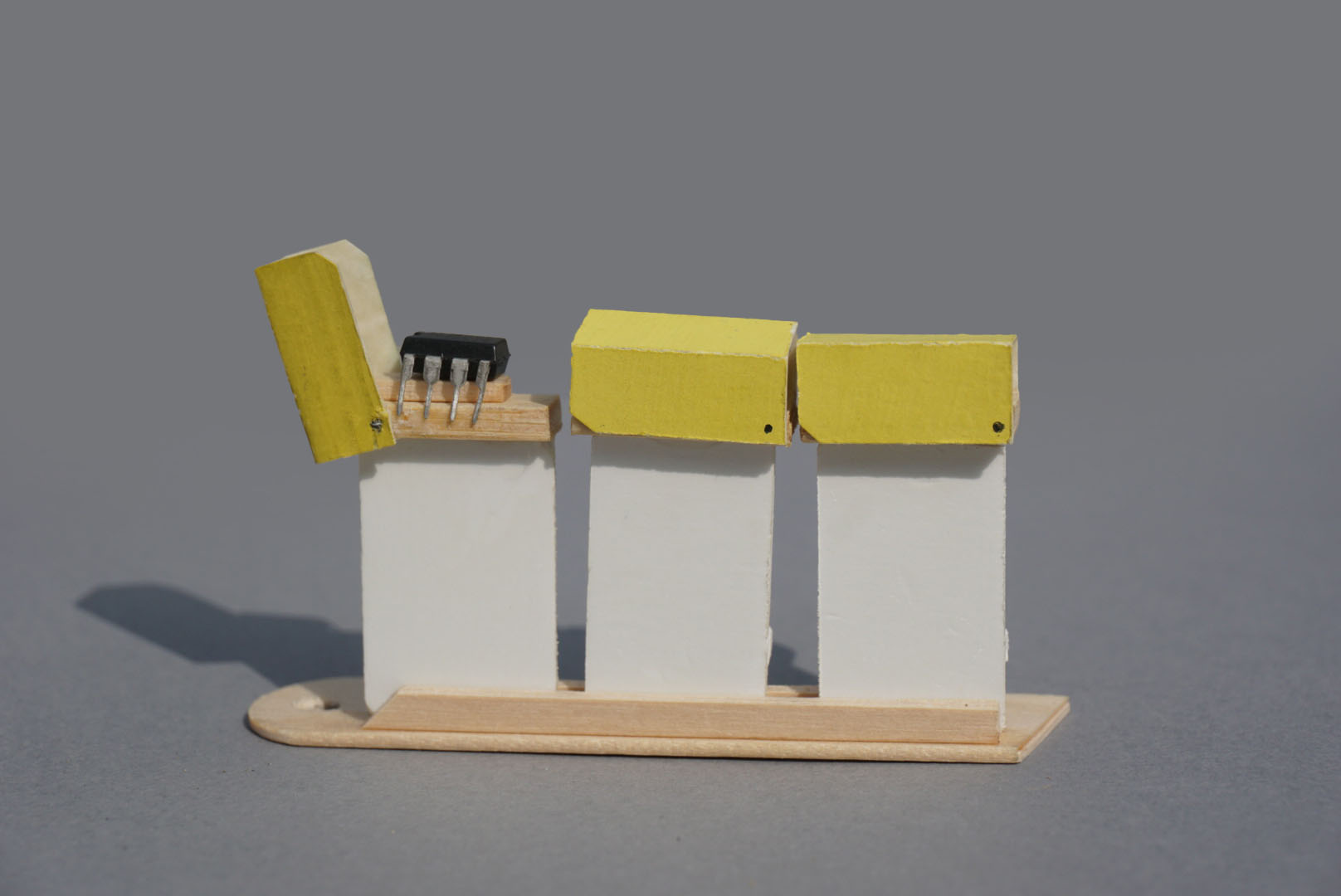

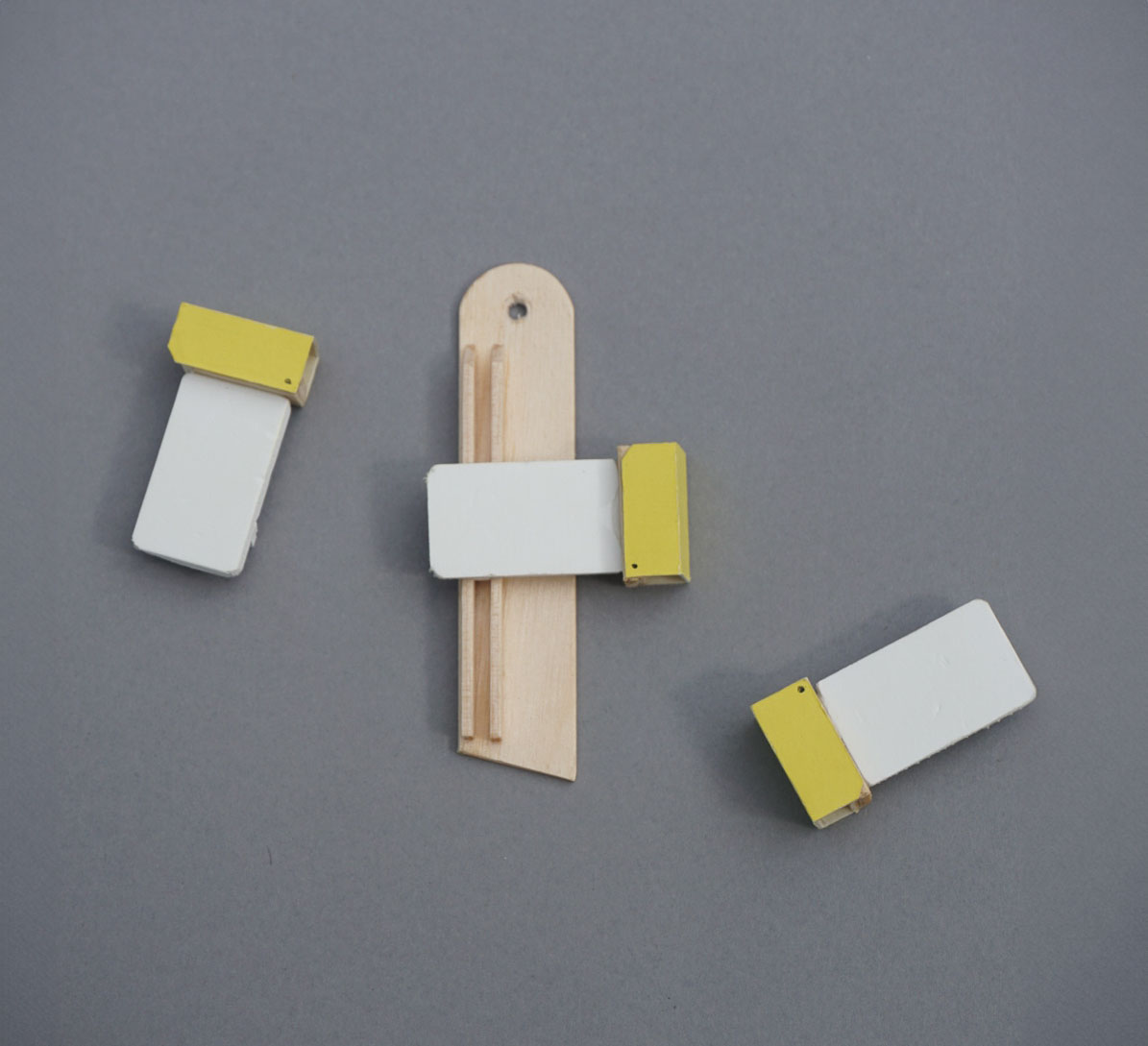

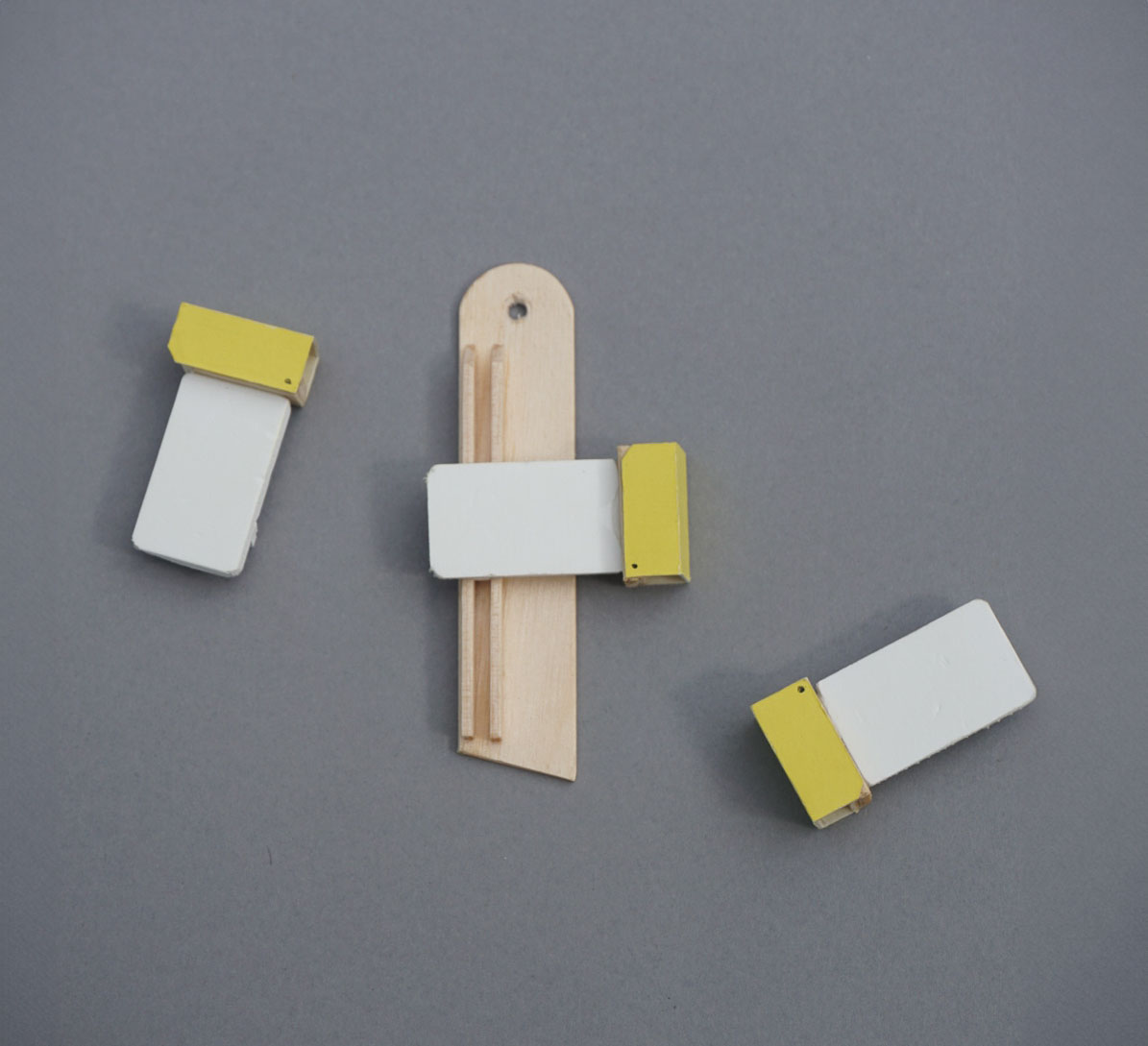

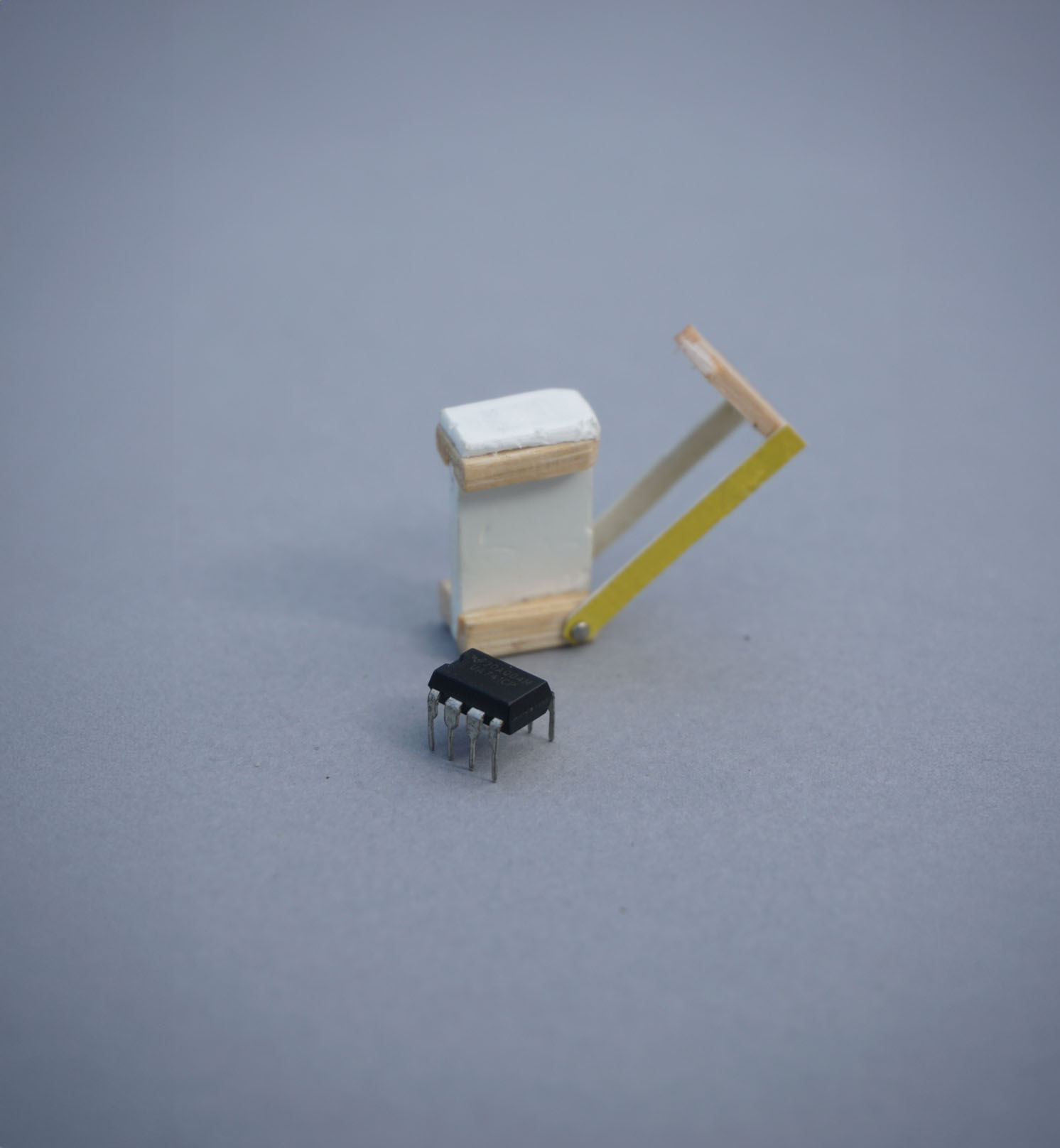

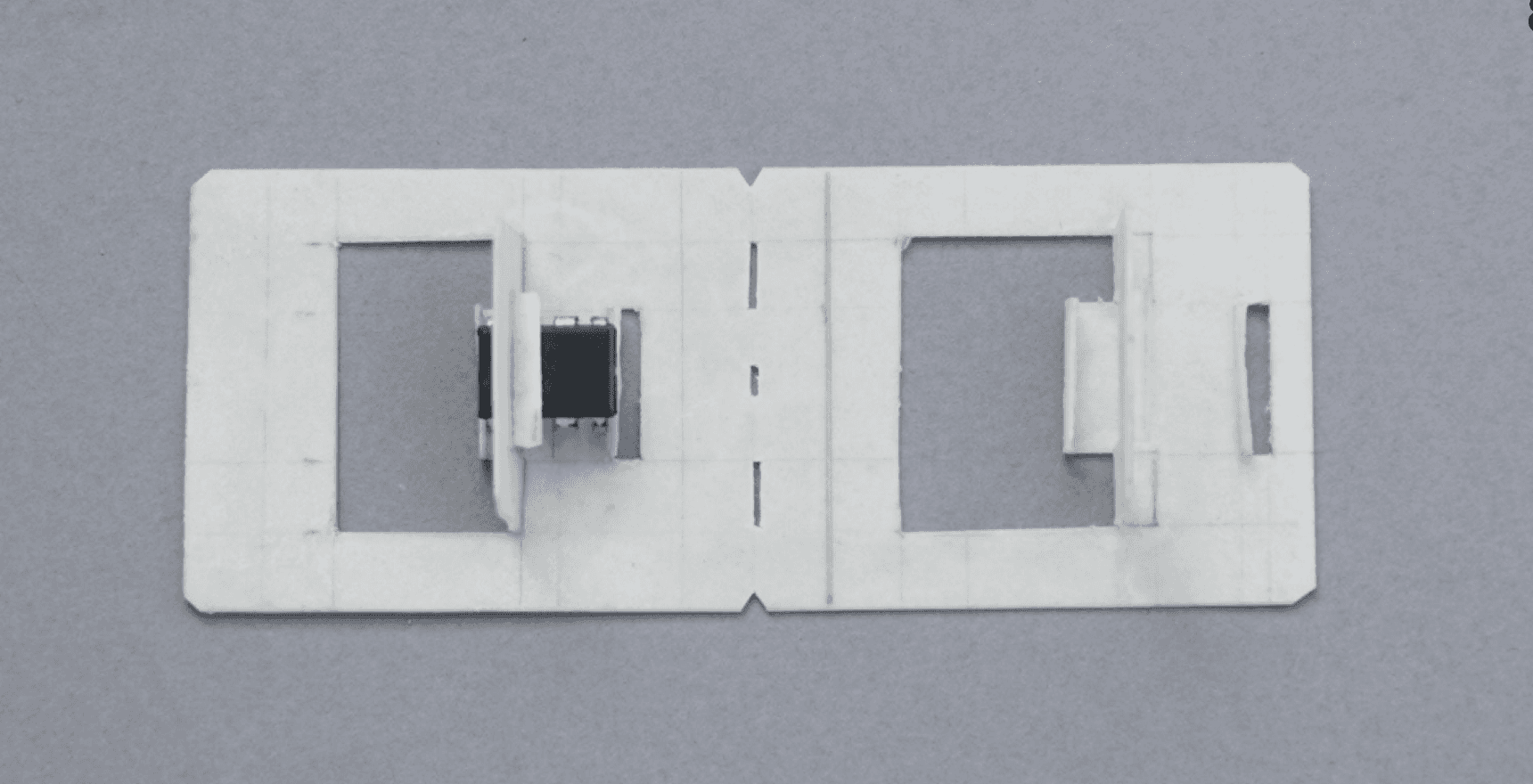

This prototype was second on the list,

but rejected for its tiny parts and

small complexities, thereby making it

less mass manufacturable.