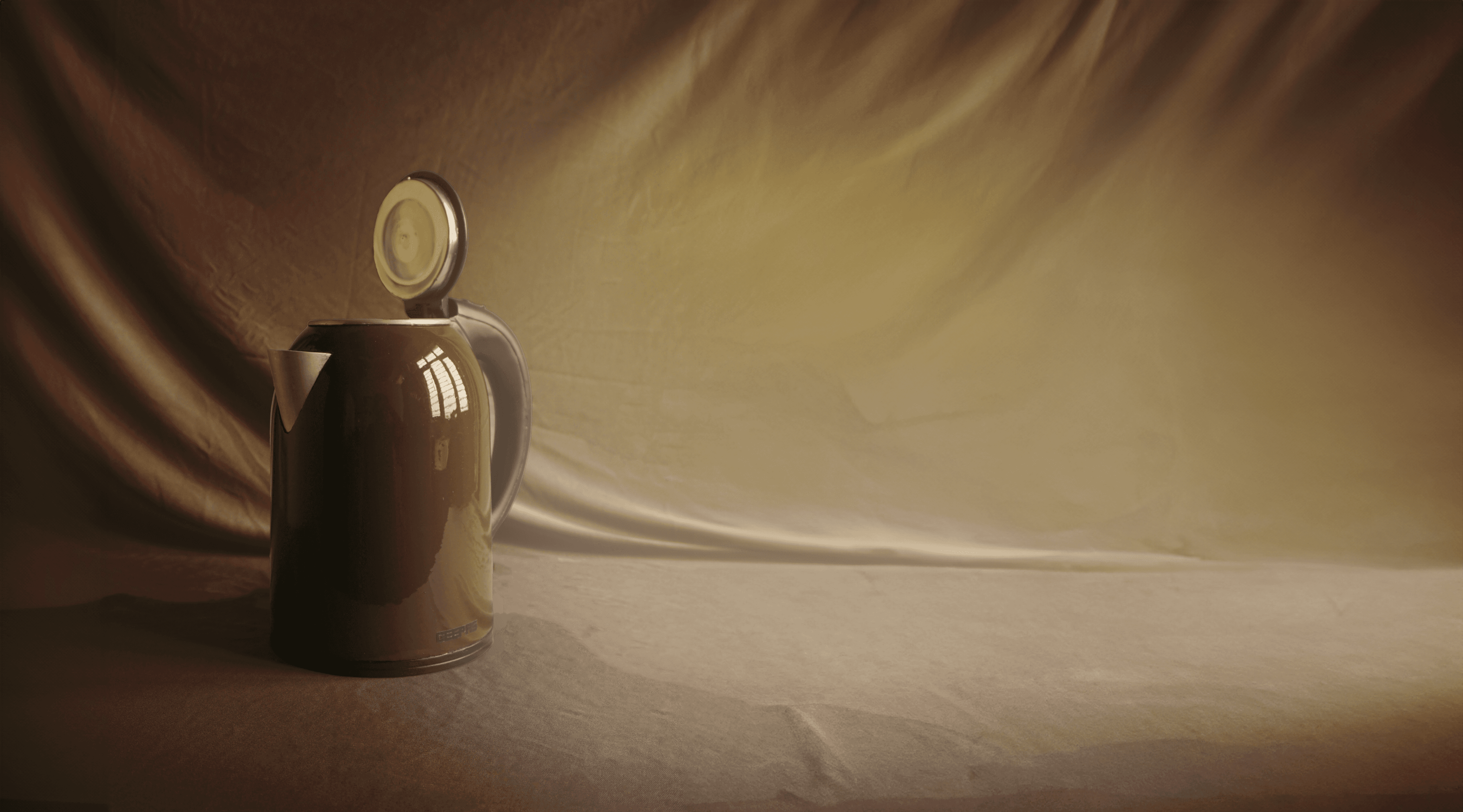

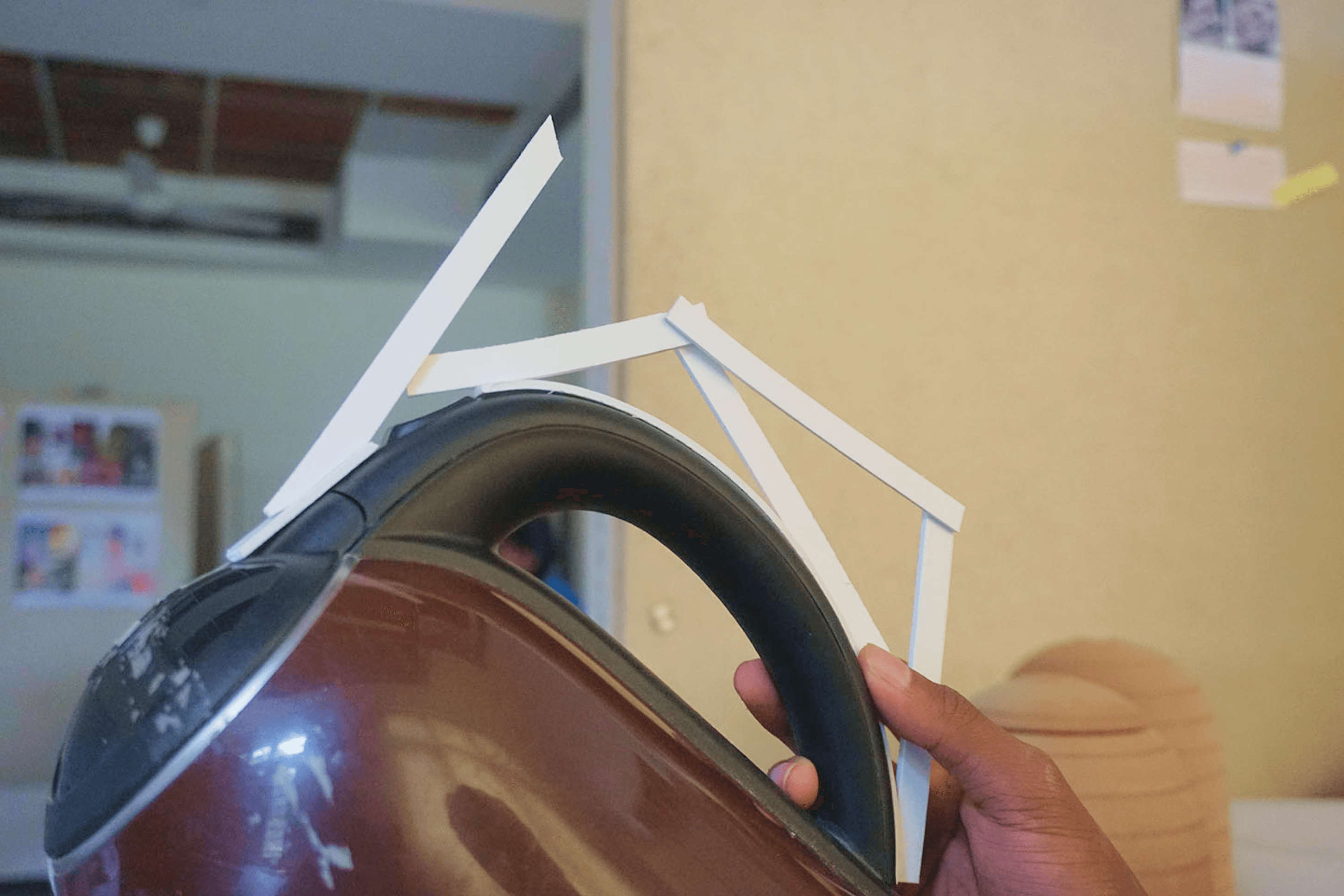

Geepas double-layered electric kettle is a blend of functionality and aesthetics

an everyday essential with thoughtful design. This project aimed to replicate it

with precision, capturing its stainless-steel body, 1.7L capacity, and striking

“Mercedes Red” finish. Beyond measurements, the challenge lay in mastering

material manipulation and finishing techniques. It was an exercise in patience

and craftsmanship, revealing the depth of design in even the simplest objects.

Key details:

Dimensions: 22 x 17 x 25 cm

Material: Stainless steel

Weight: 1.32 kg

Color: Mercedes Red

Capacity: 1.7 L

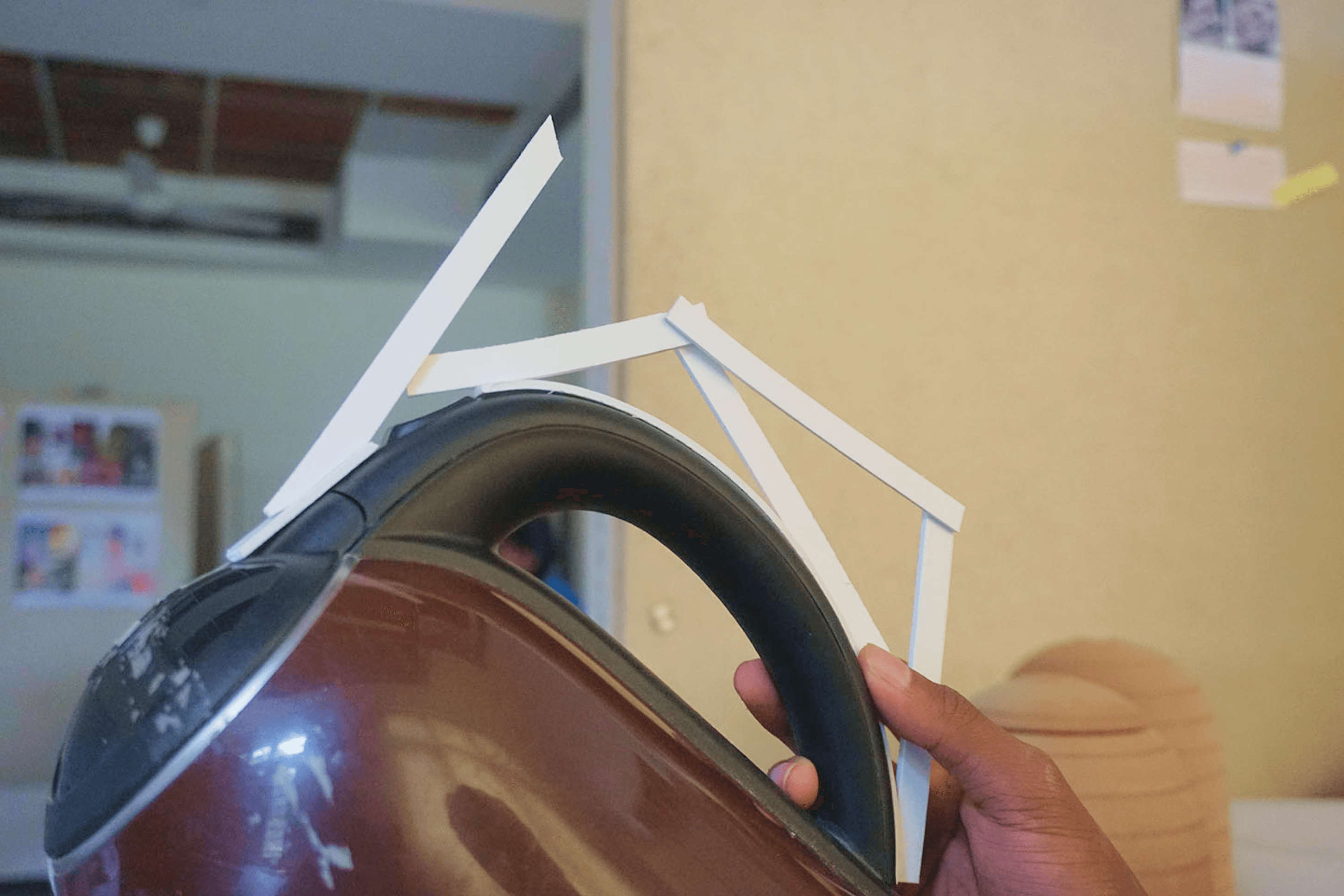

Geepas double-layered electric kettle is a blend of functionality and aesthetics

an everyday essential with thoughtful design. This project aimed to replicate it

with precision, capturing its stainless-steel body, 1.7L capacity, and striking

“Mercedes Red” finish. Beyond measurements, the challenge lay in mastering

material manipulation and finishing techniques. It was an exercise in patience

and craftsmanship, revealing the depth of design in even the simplest objects.

Key details:

Dimensions: 22 x 17 x 25 cm

Material: Stainless steel

Weight: 1.32 kg

Color: Mercedes Red

Capacity: 1.7 L

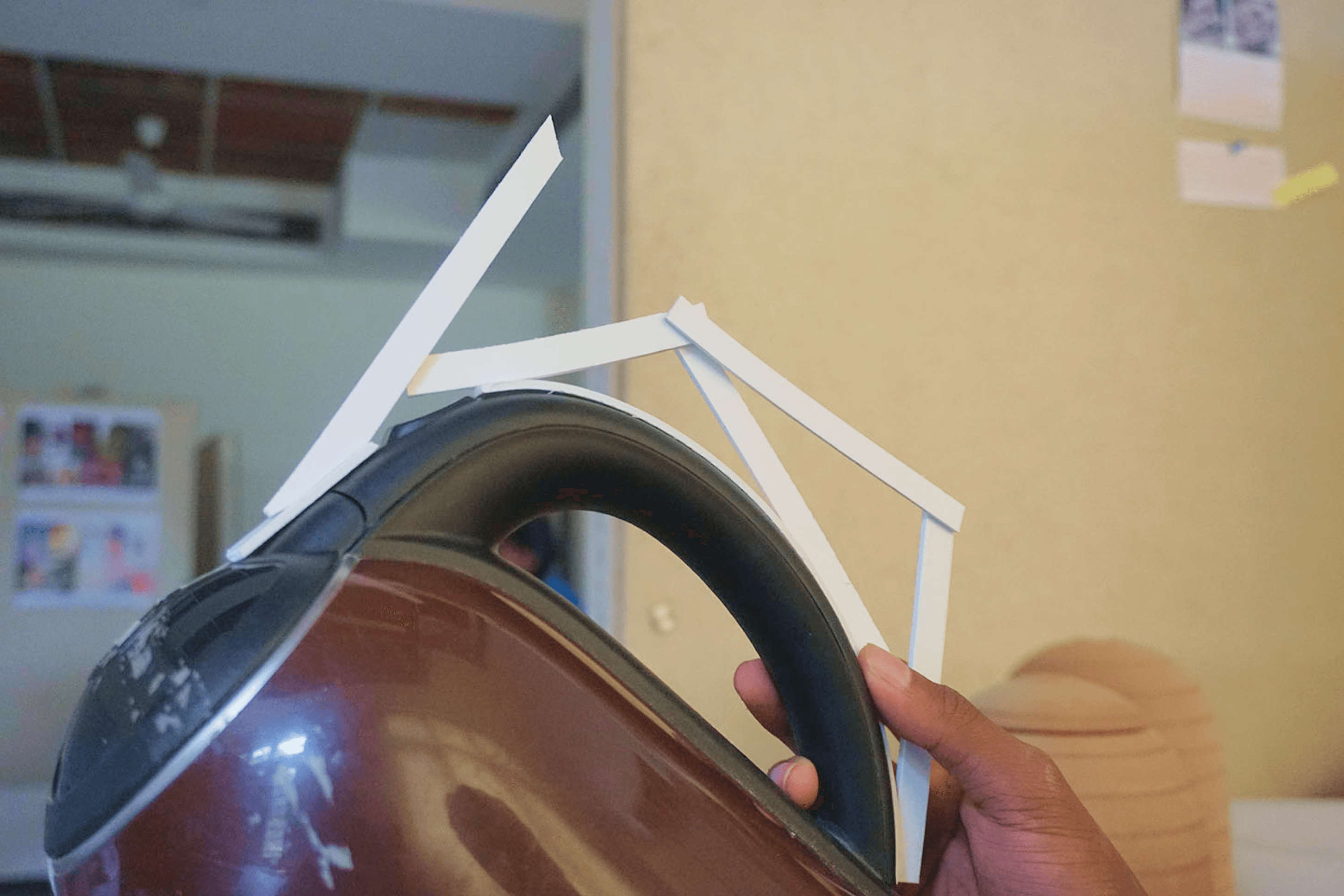

Geepas double-layered electric kettle is a blend of functionality and aesthetics

an everyday essential with thoughtful design. This project aimed to replicate it

with precision, capturing its stainless-steel body, 1.7L capacity, and striking

“Mercedes Red” finish. Beyond measurements, the challenge lay in mastering

material manipulation and finishing techniques. It was an exercise in patience

and craftsmanship, revealing the depth of design in even the simplest objects.

Key details:

Dimensions: 22 x 17 x 25 cm

Material: Stainless steel

Weight: 1.32 kg

Color: Mercedes Red

Capacity: 1.7 L

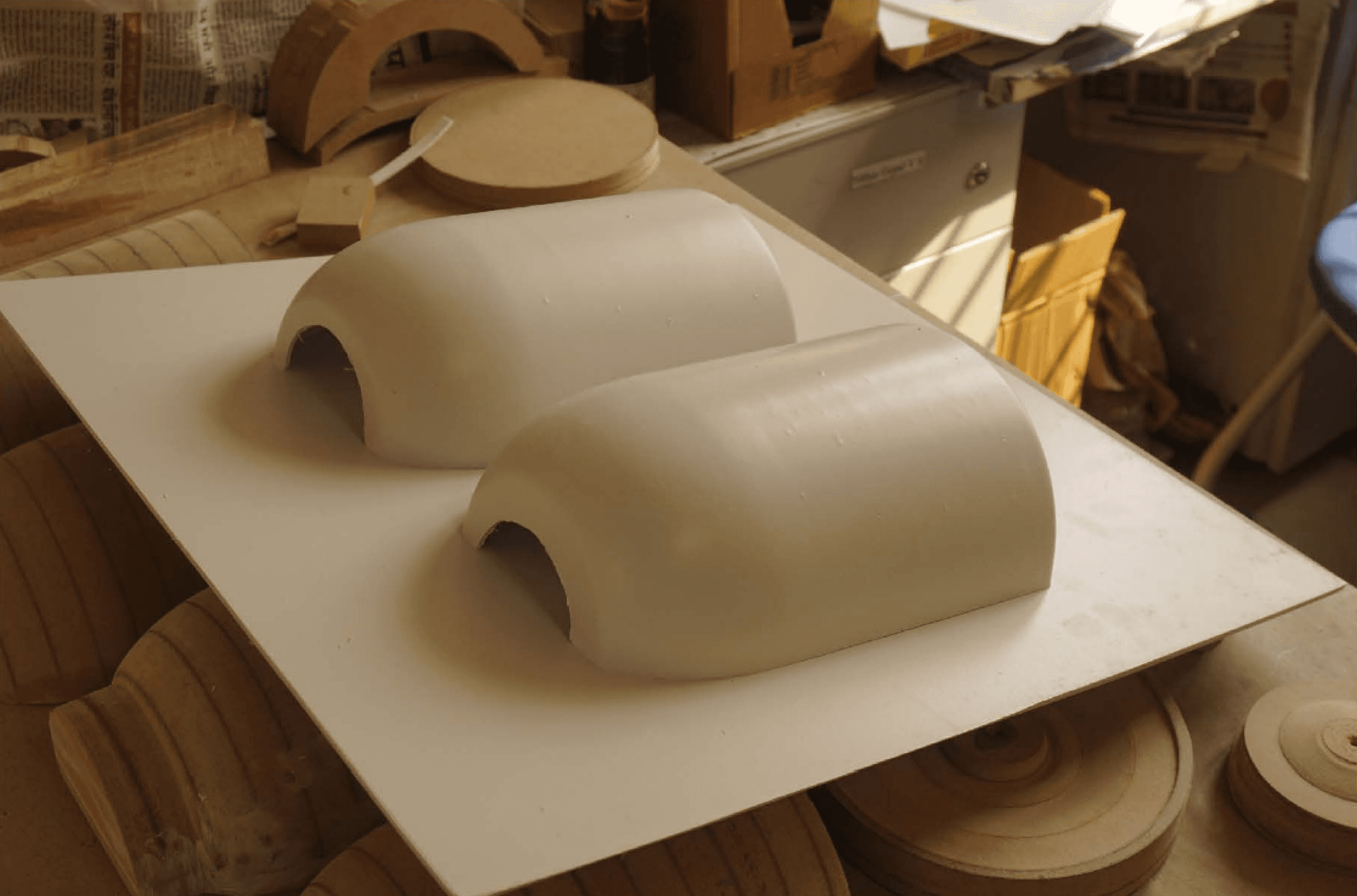

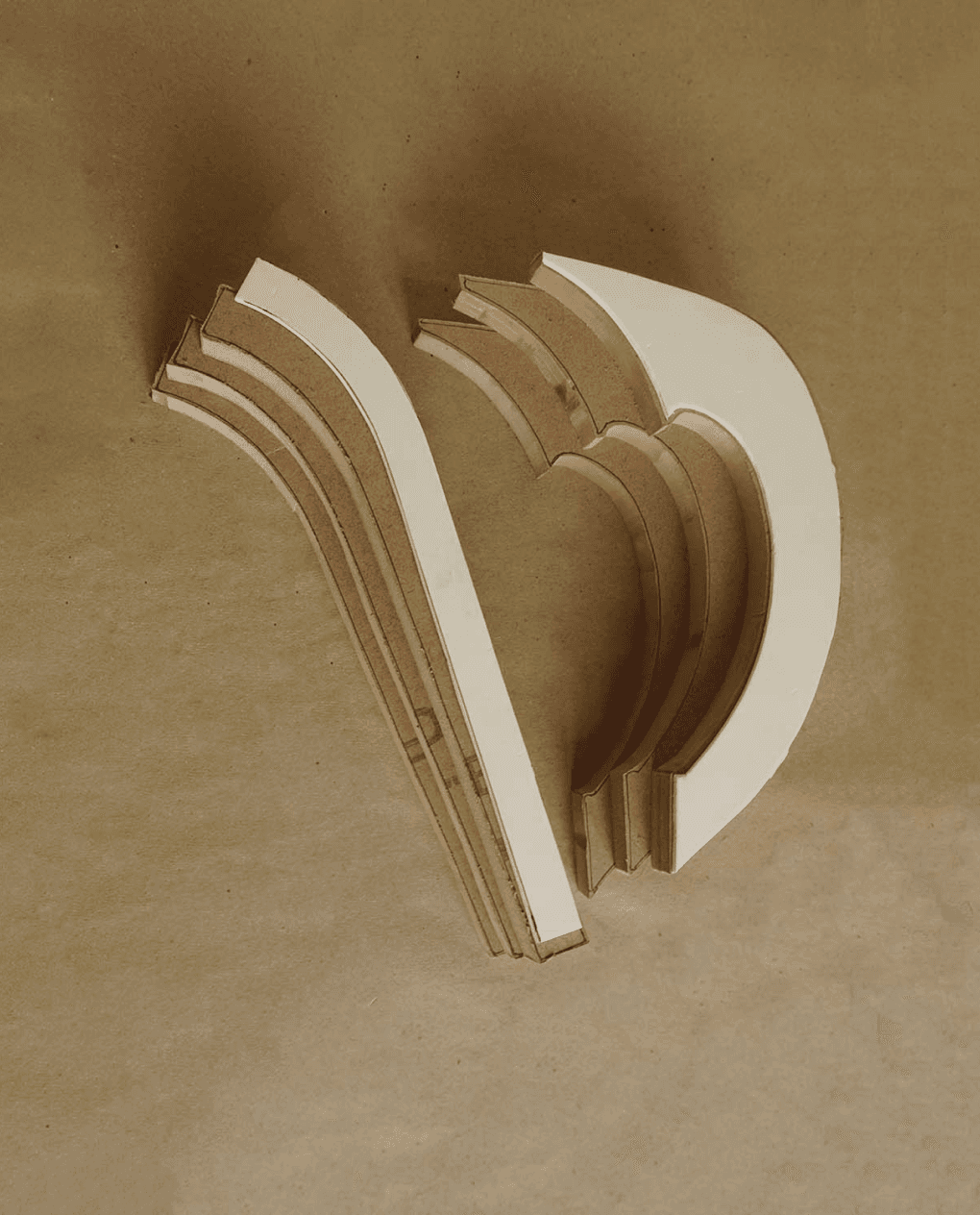

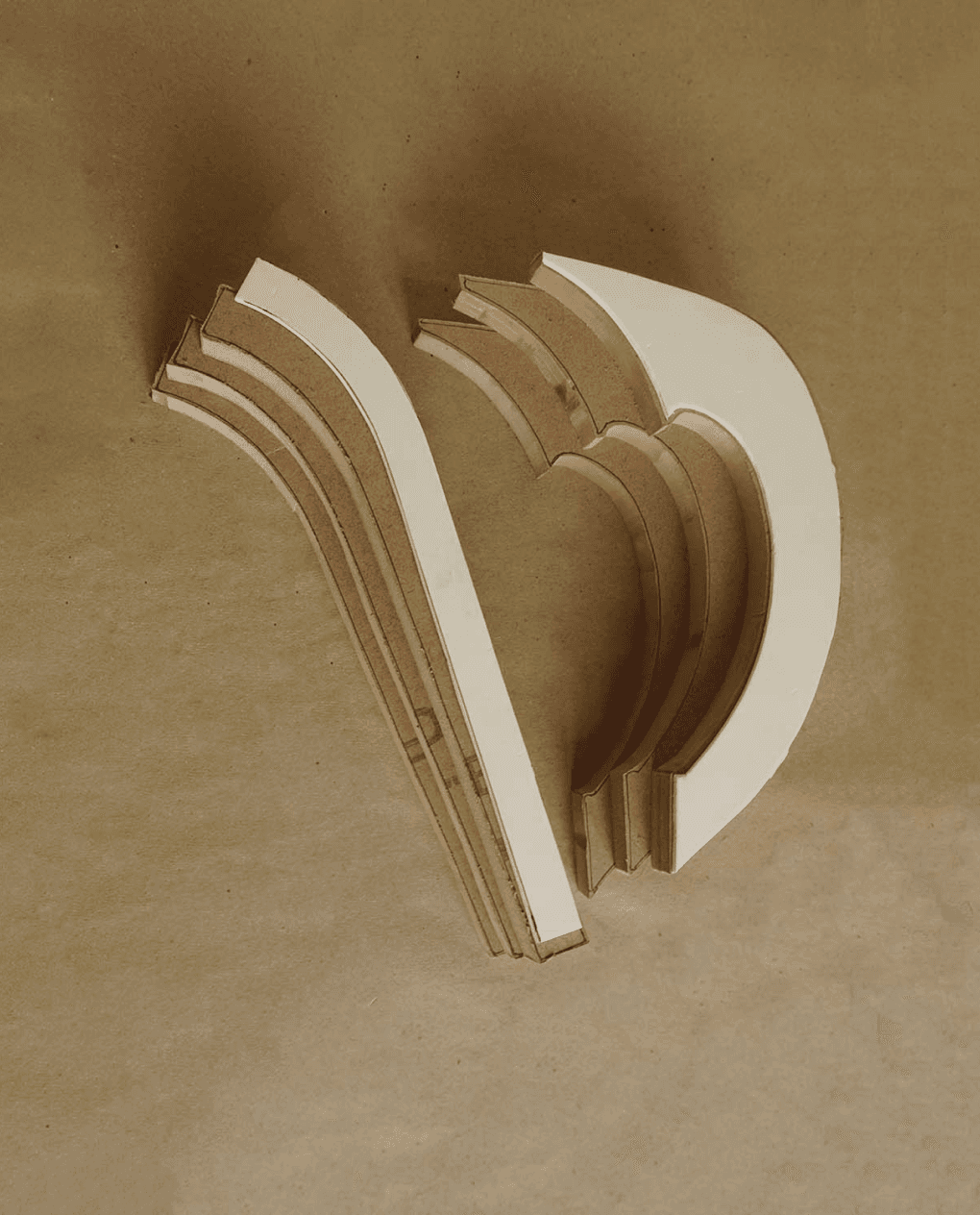

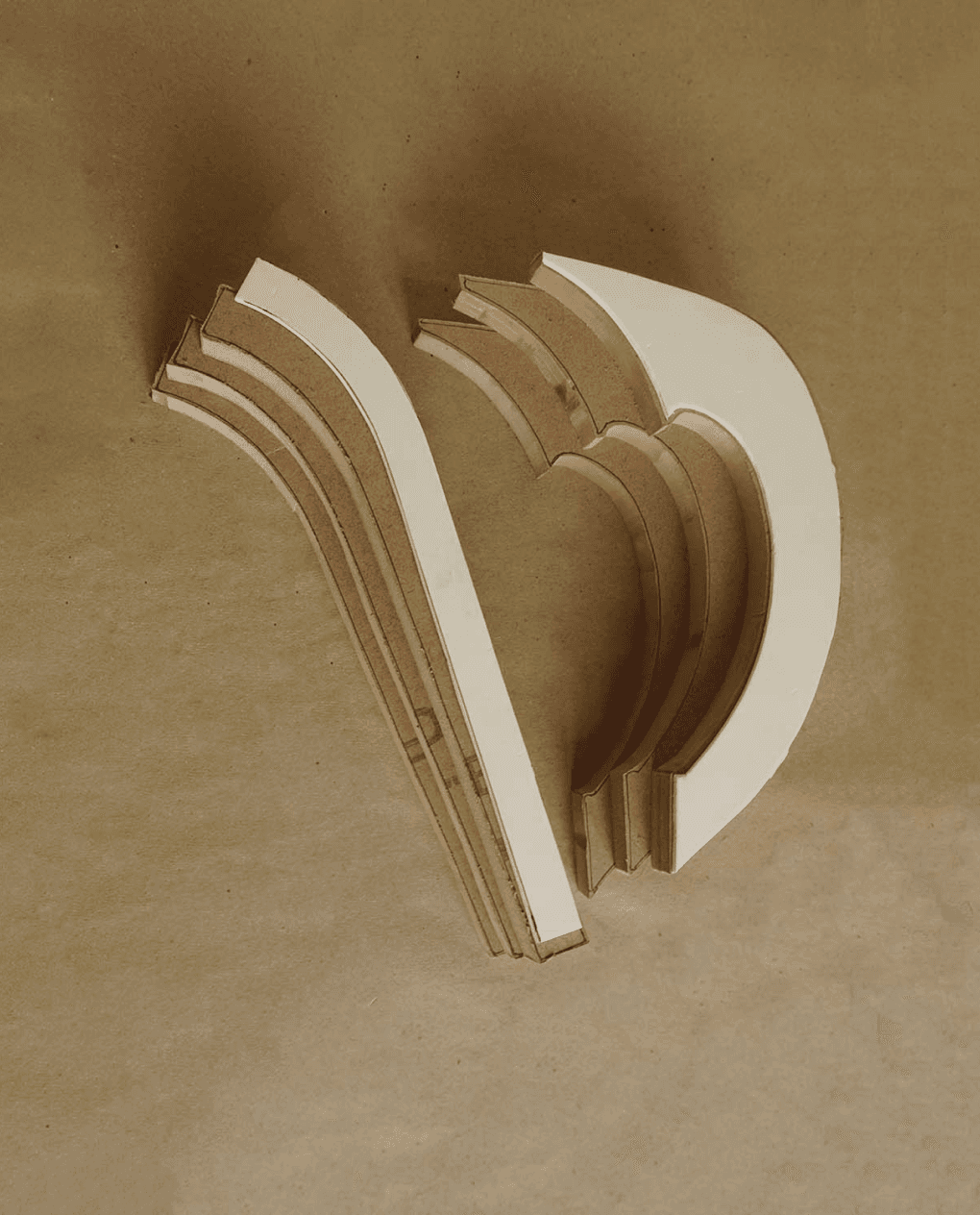

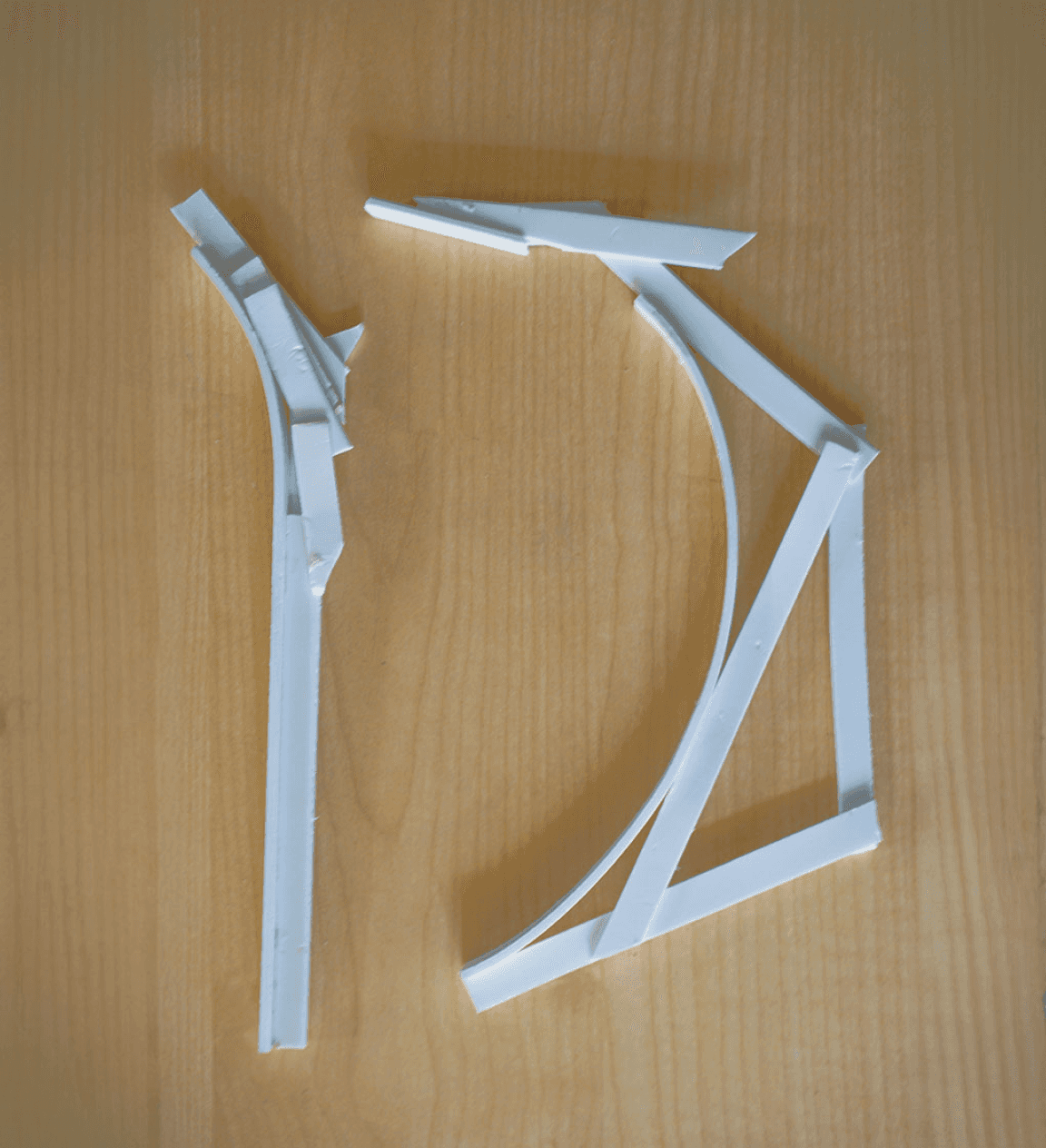

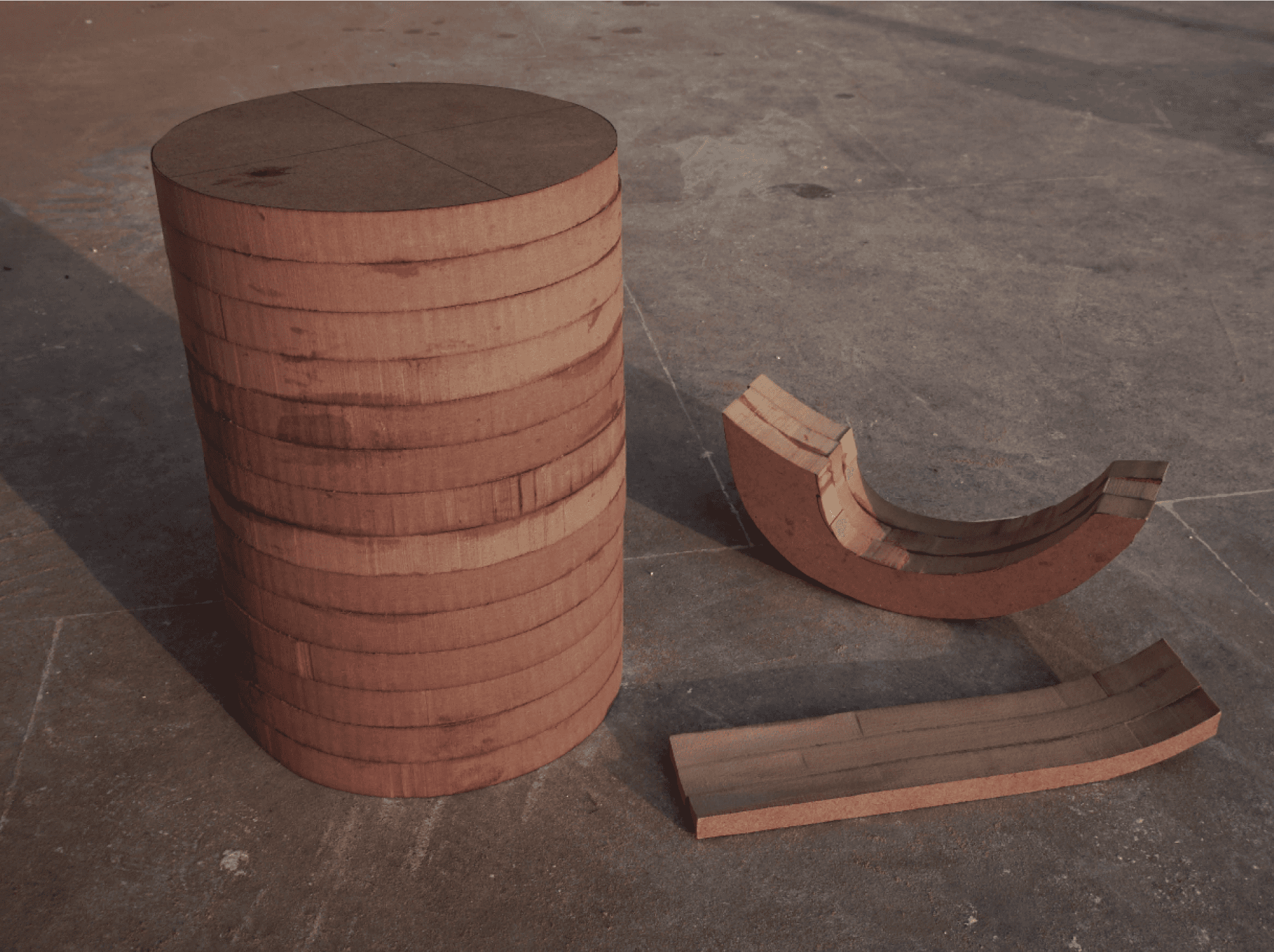

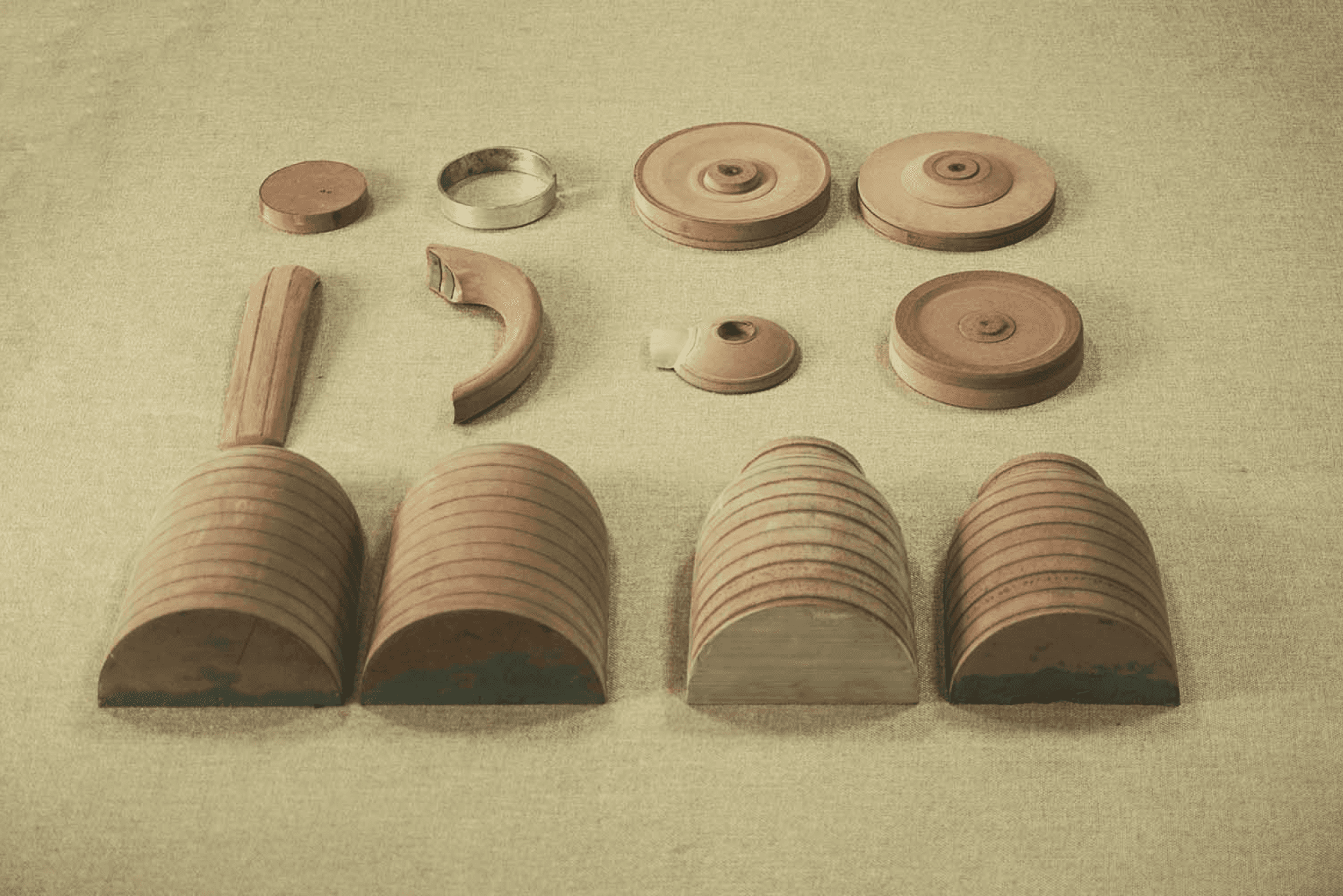

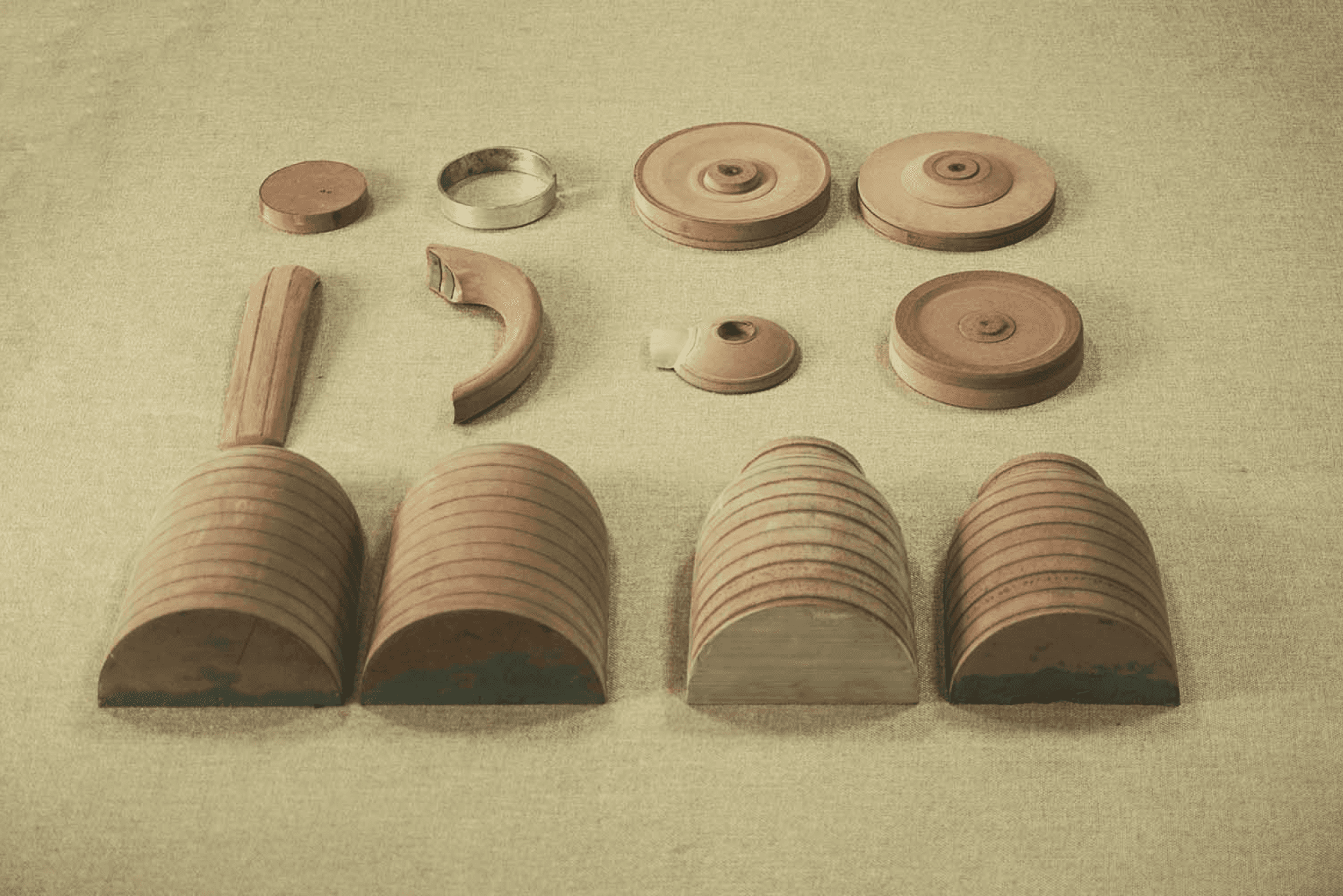

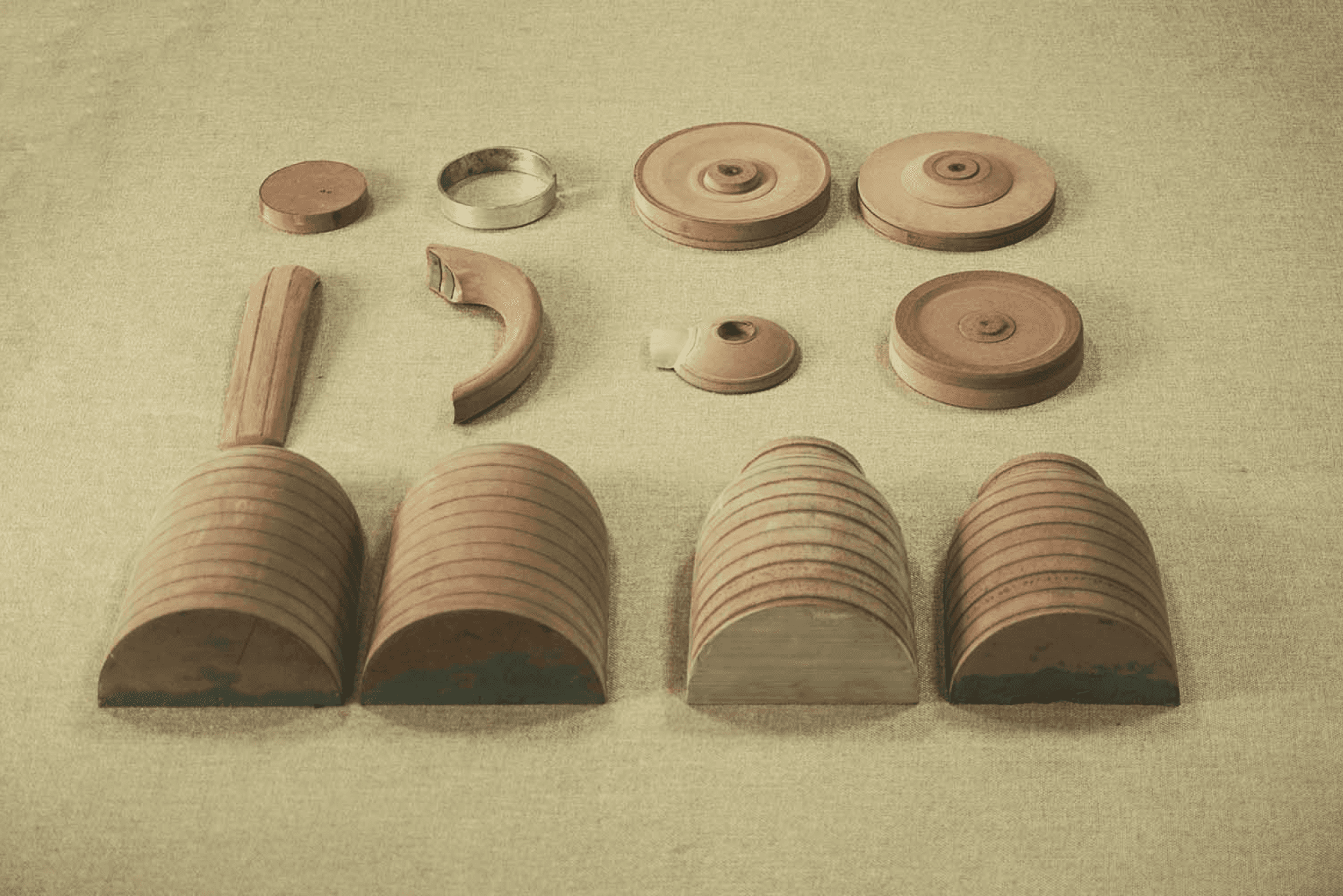

The entire mold was glued in two bundles and then

glued together, the same for handles and handle base.

Later the material was subtracted using an angle grinder.

The entire mold was glued in two bundles and then

glued together, the same for handles and handle base.

Later the material was subtracted using an angle grinder.

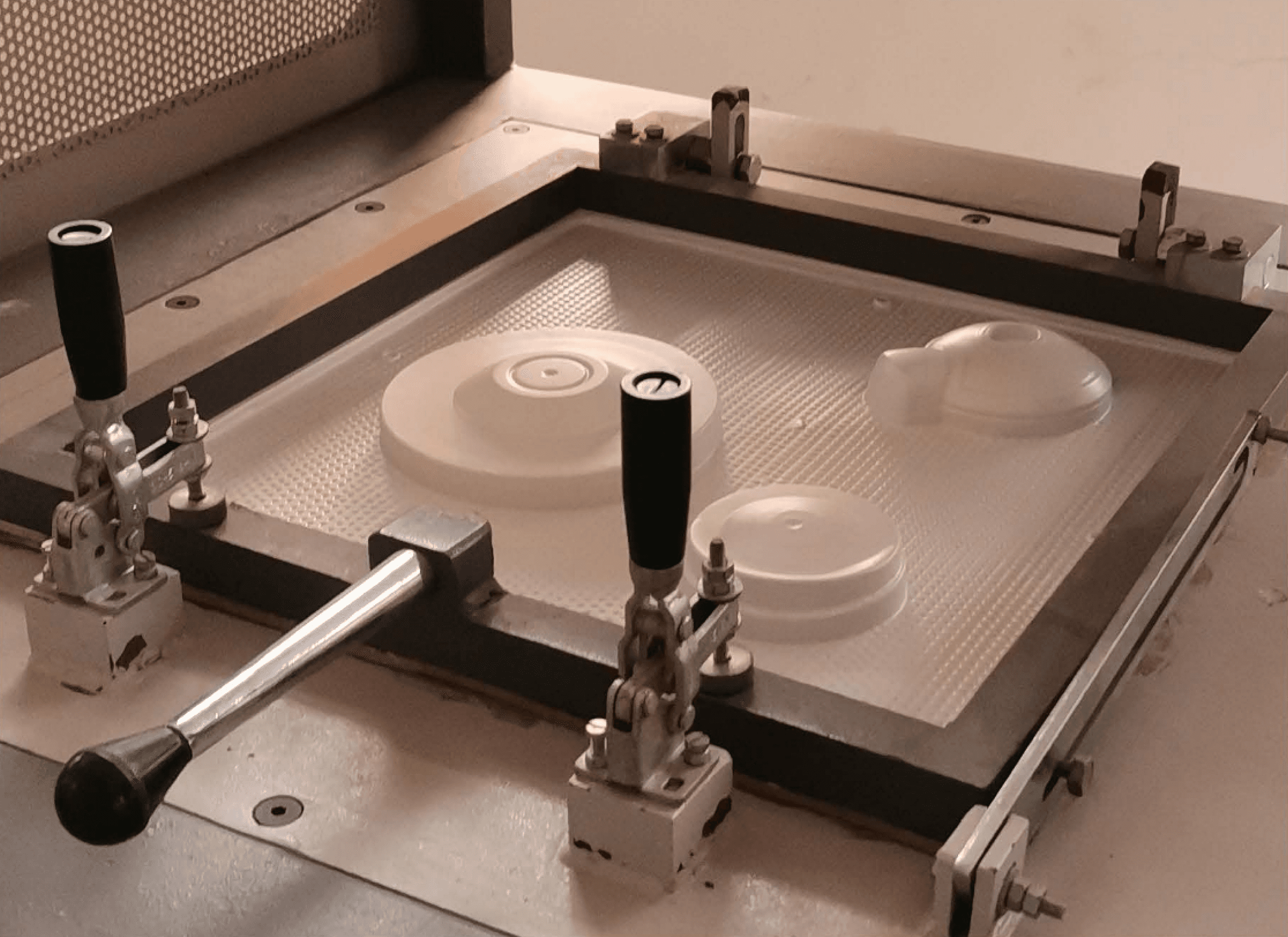

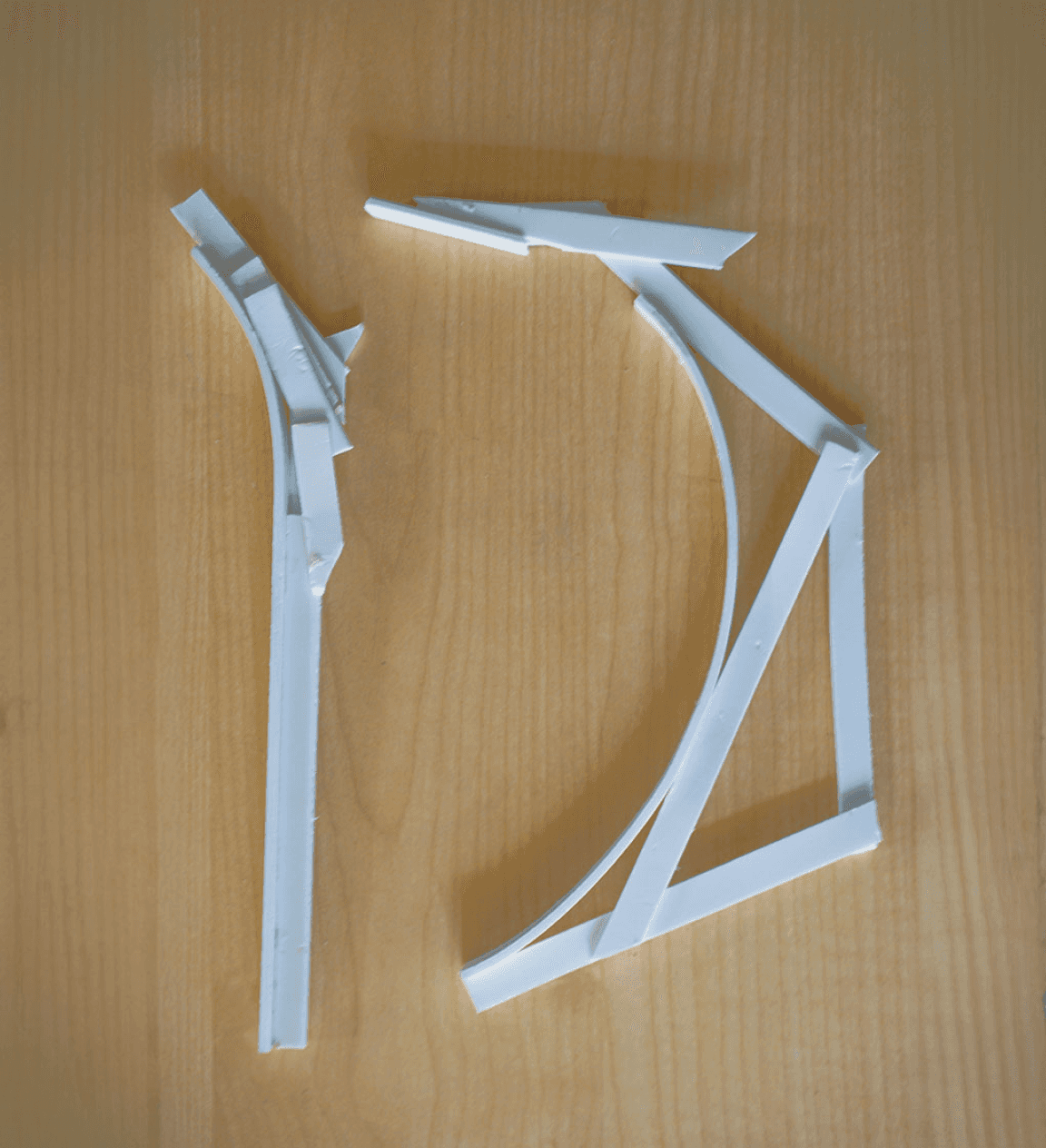

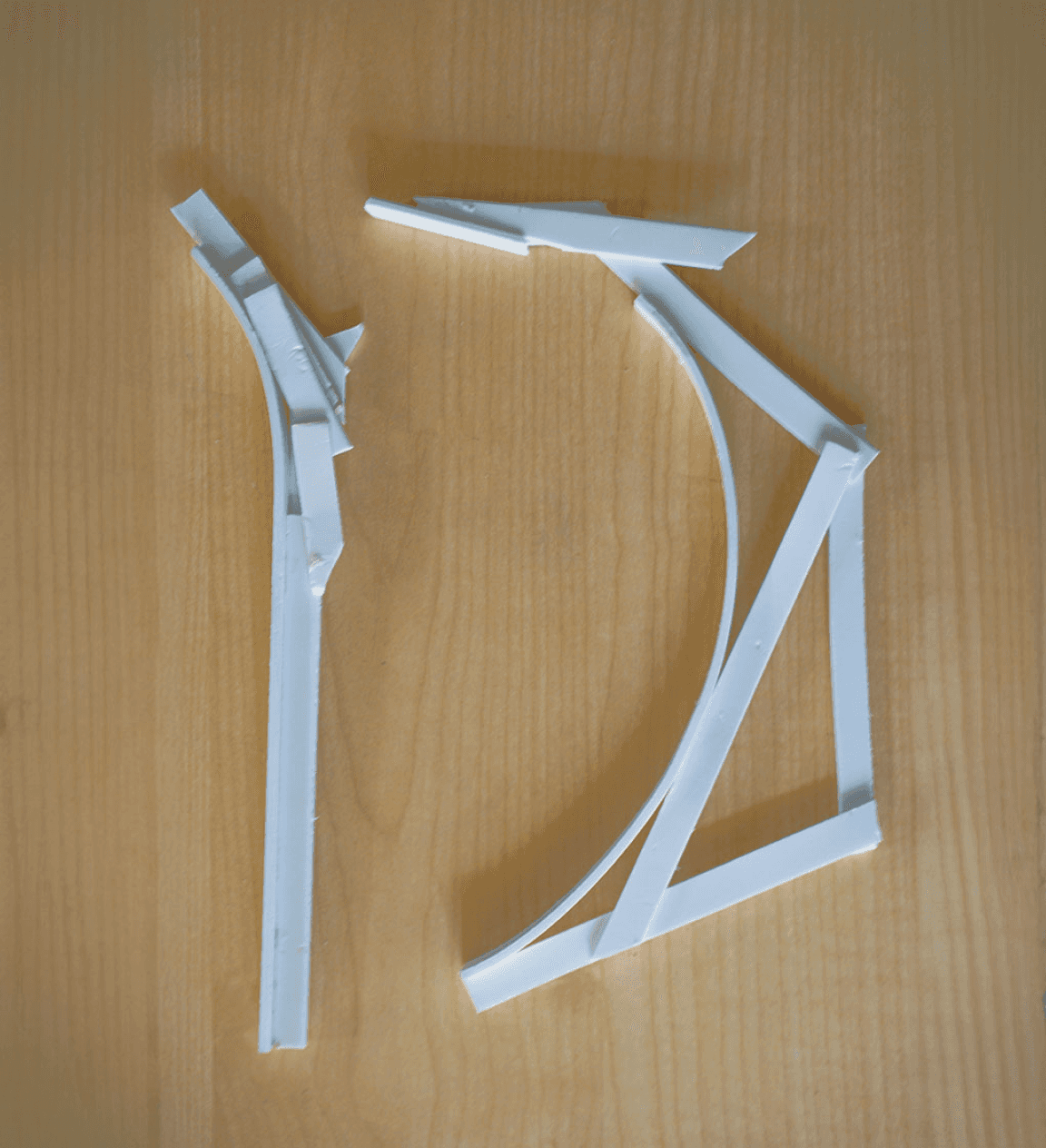

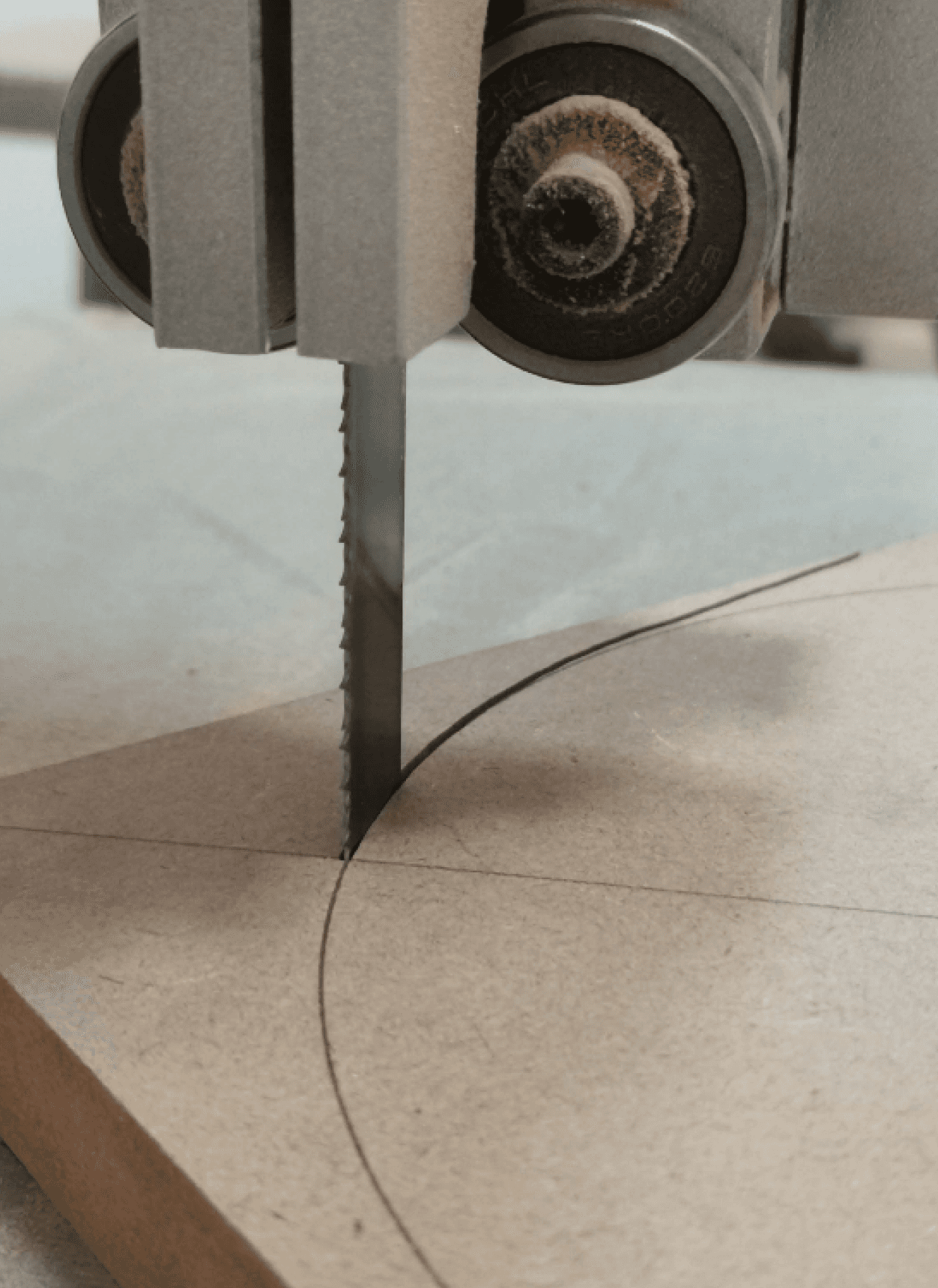

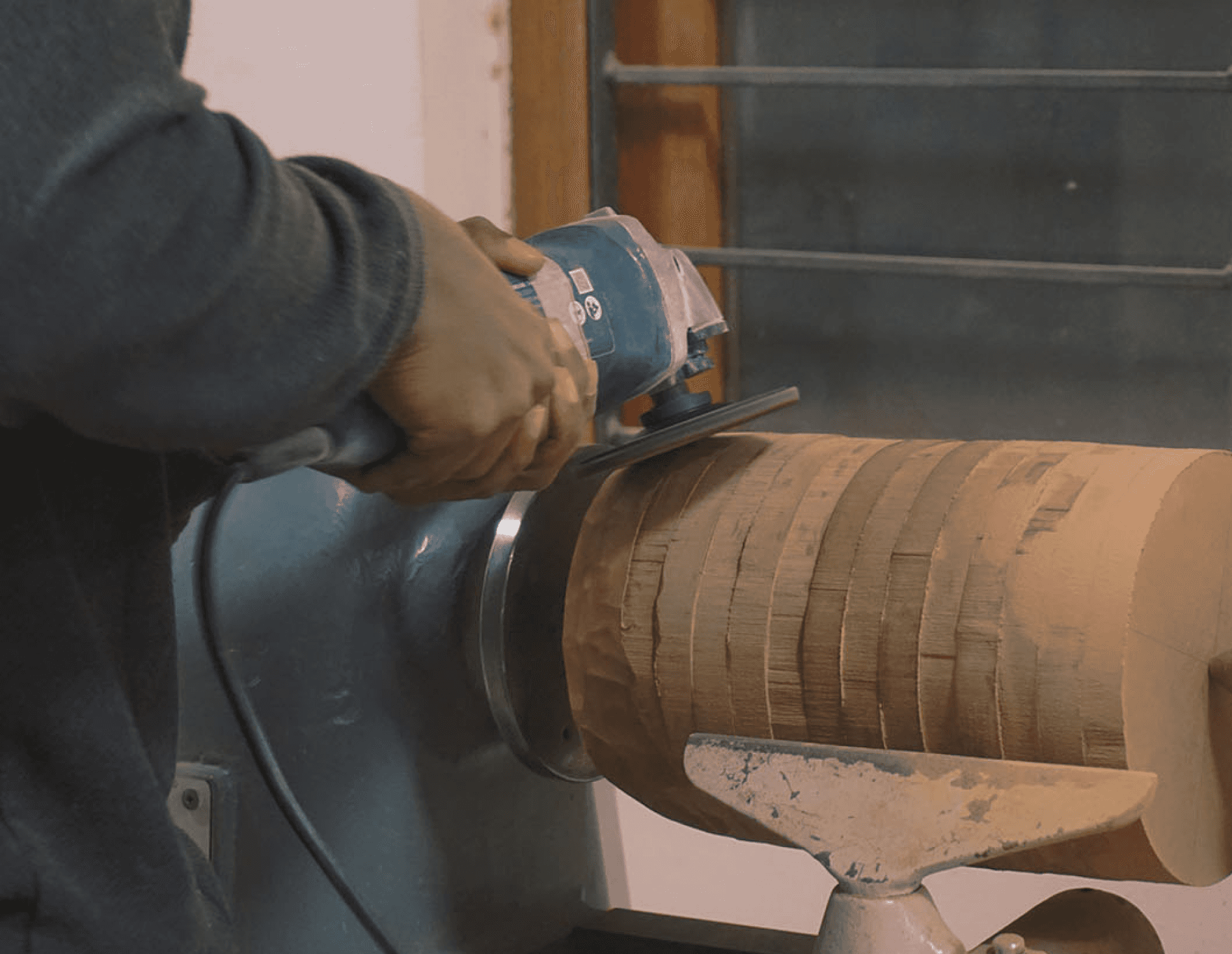

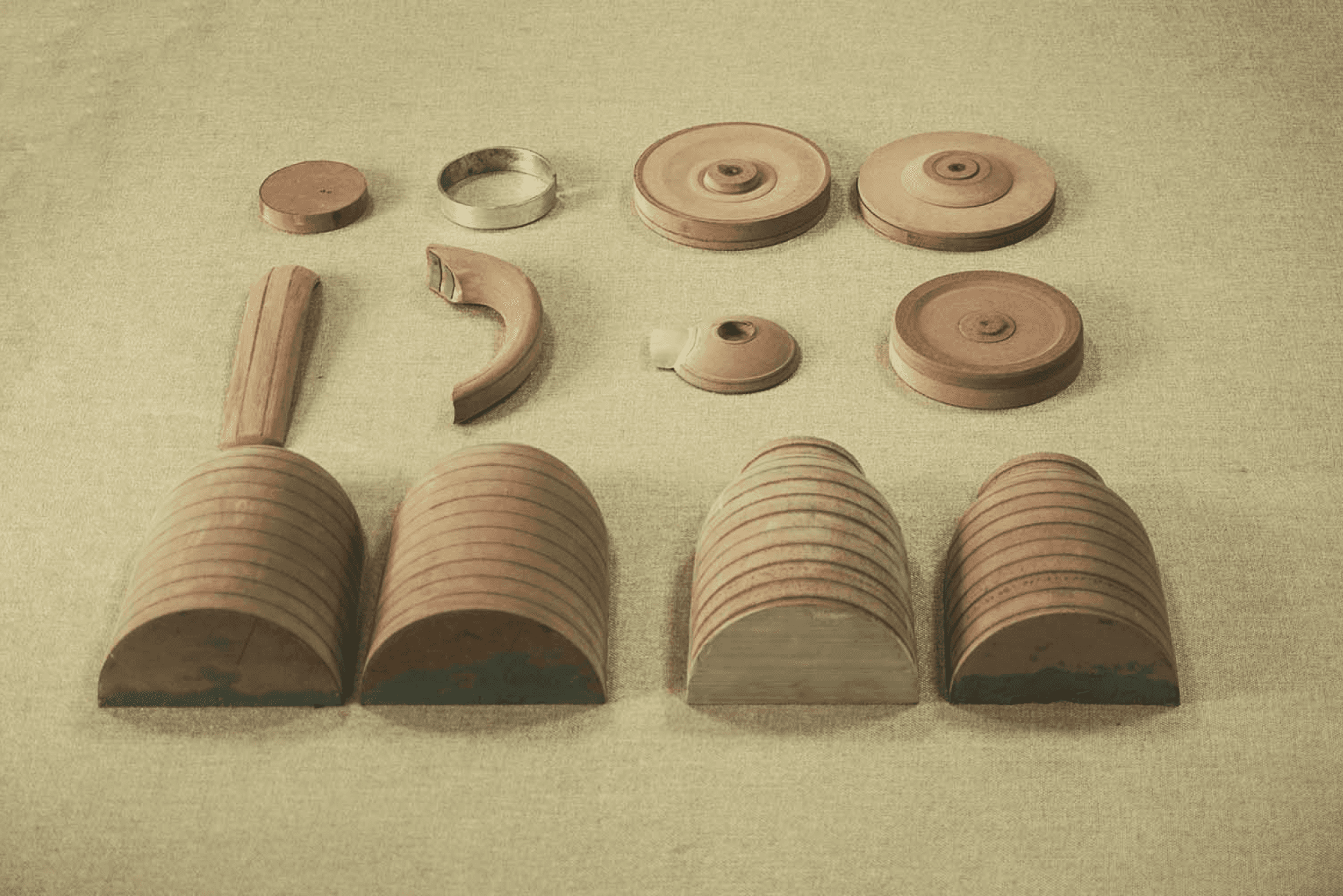

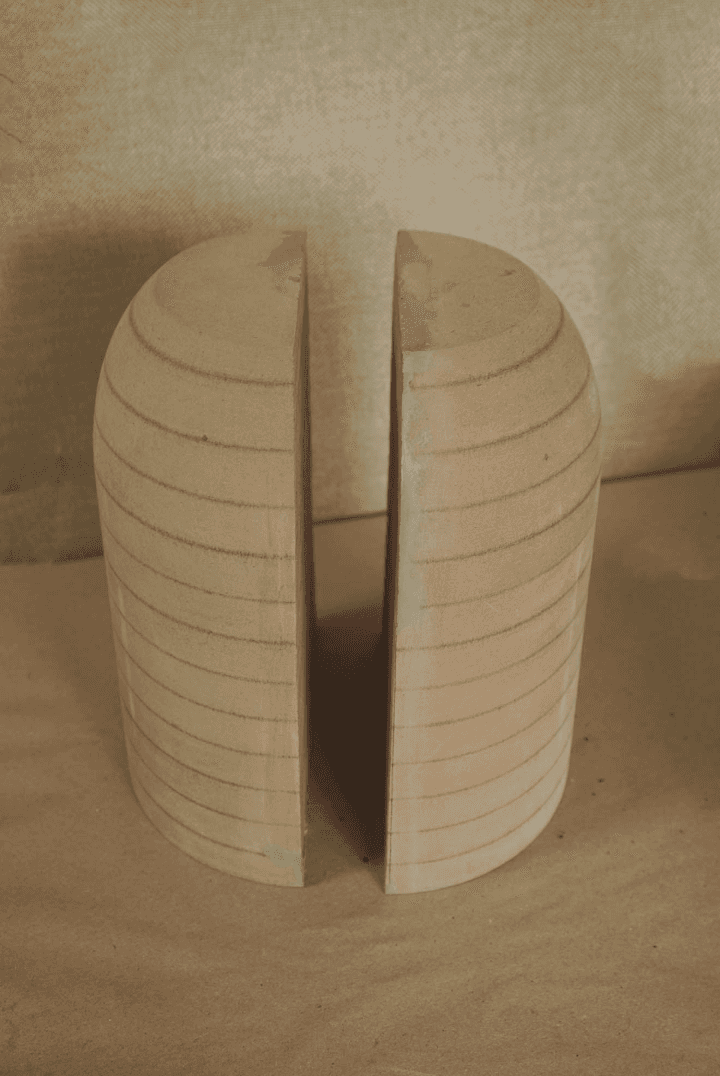

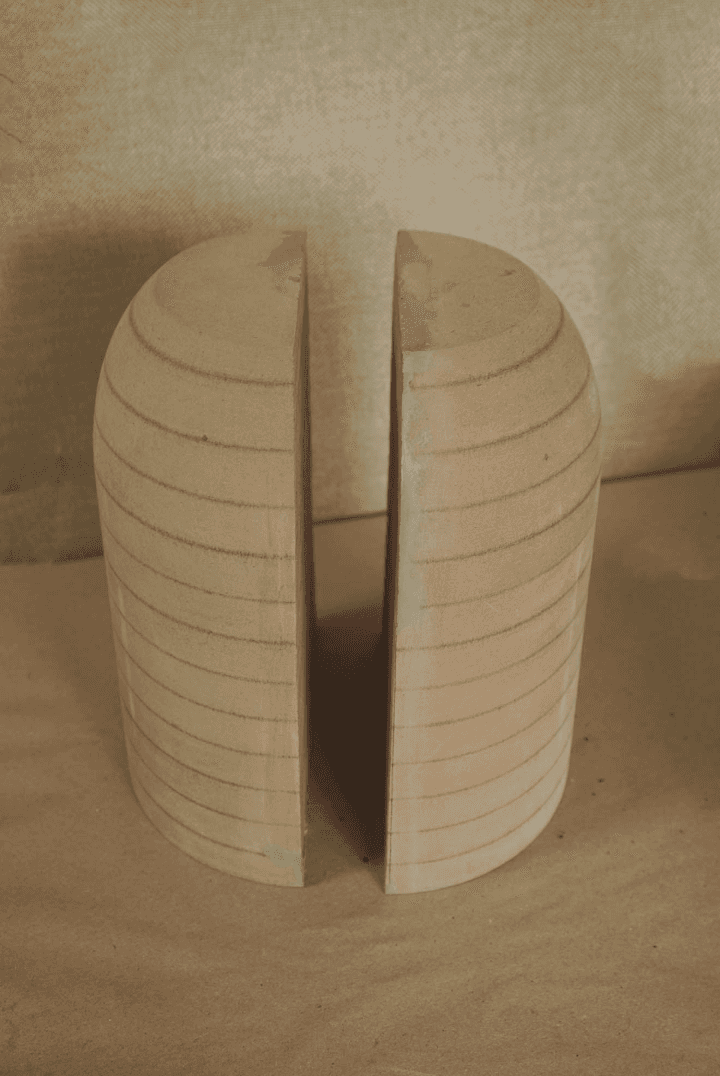

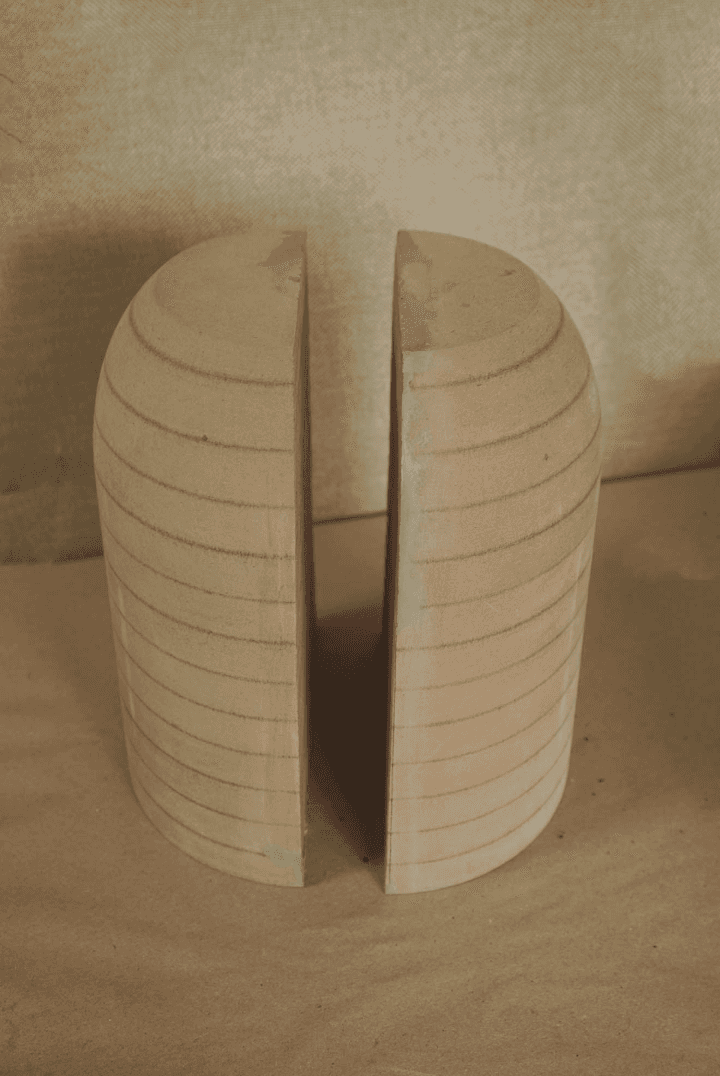

The mould was then turned using a lathe machine to achieve

the desired shape.

The mould was then turned using a lathe machine to achieve

the desired shape.

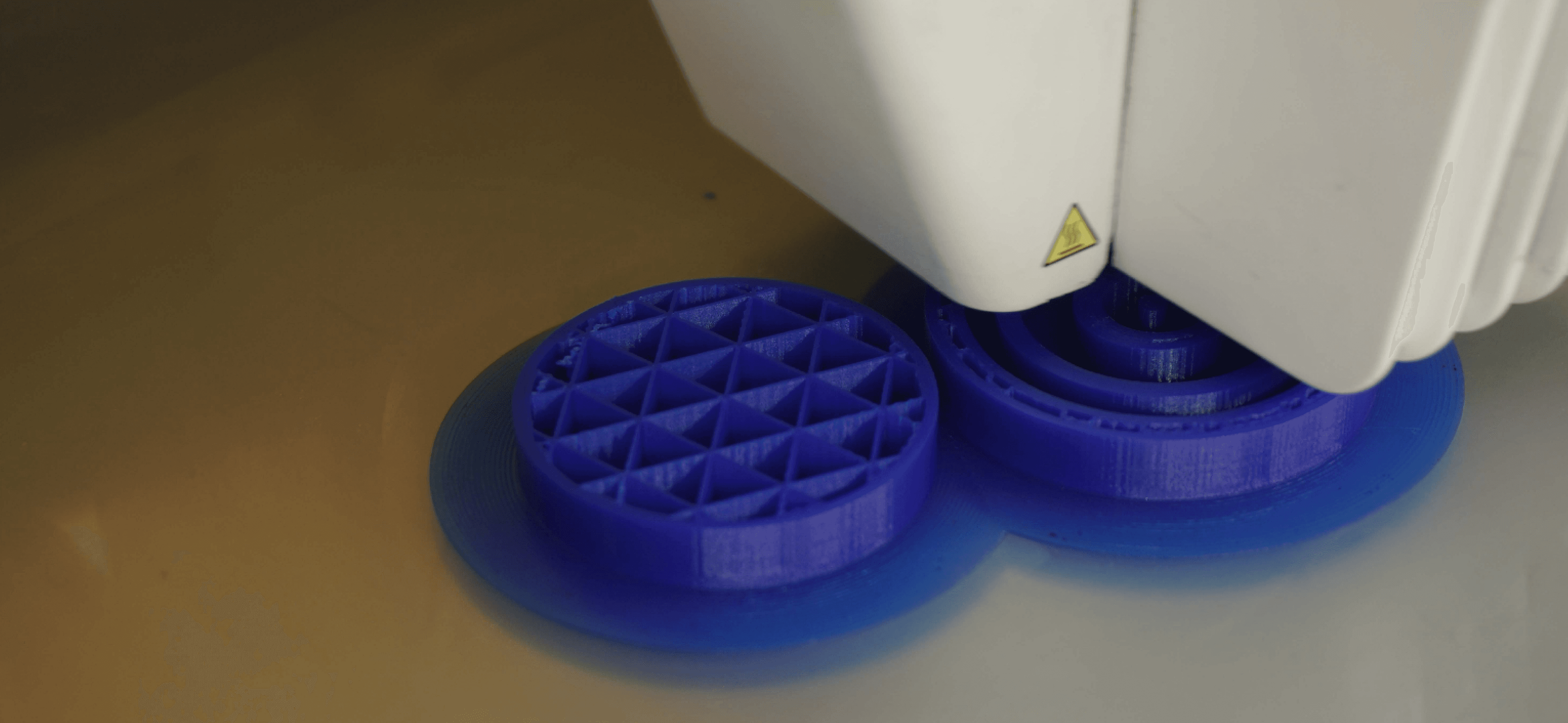

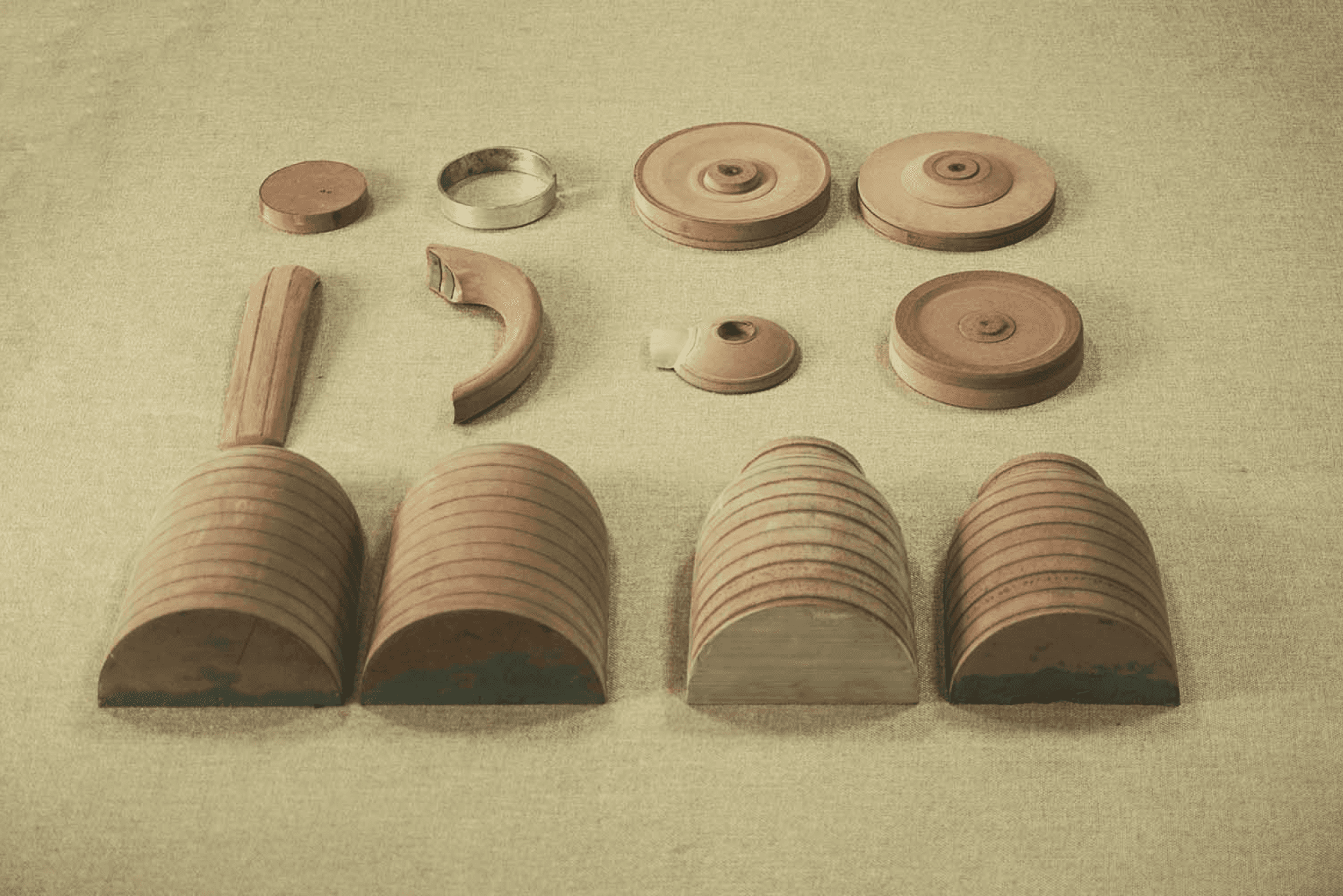

The shape was cut into two halves

for vacuum molding. The beak and top ring were made from a 5mm aluminum sheet.